Description

Overview of Vacuum Degassers

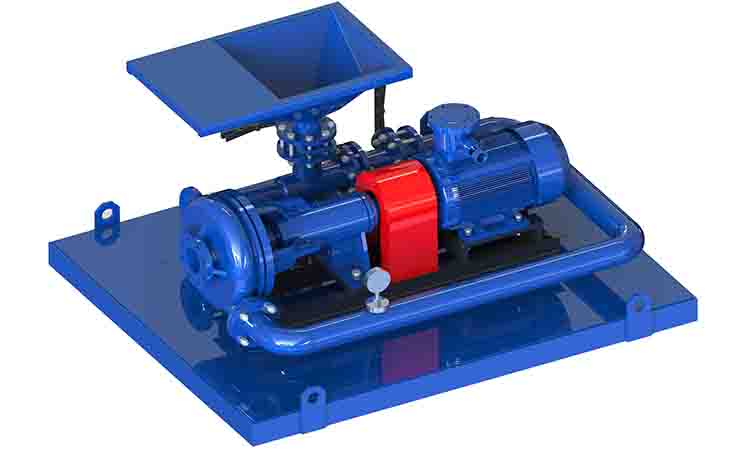

Vacuum degasser is a special equipment used to deal with gas immersion drilling fluid. Vacuum degasser removes dissolved gas including H2S and corrosive oxygen from a liquid solution by lowering the pressure inside a vessel containing the solution. It is suitable for all kinds of matching and plays an important role in restoring the specific gravity of the mud, stabilizing the viscosity performance of the mud, and reducing drilling costs. At the same time, the vacuum degasser can also be used as a high-power agitator, which is suitable for supporting various mud circulation purification systems. The vacuum degasser is a negative pressure degasser. The vacuum degasser plays an important role in restoring the specific gravity of the mud, stabilizing the viscosity performance of the mud, and reducing the drilling cost.

The drilling fluid vacuum degasser is mainly used to remove the gas intruding into the drilling fluid, which does not belong to the scope of solid control. However, because gas invasion has great harm to the specific gravity, viscosity performance and density of drilling fluid, a degassing device is usually used.

Drilling fluid degasser generally includes vacuum degasser, jet degasser and centrifugal degasser. Vacuum degasser, also known as negative pressure degasser, centrifugal vacuum degasser, drilling fluid degasser, can quickly remove various gases intruded into drilling fluid. It is usually suitable for all kinds of mud circulation and purification systems.

The drilling fluid vacuum degasser is usually installed after the drilling fluid shale shaker, which can effectively separate the harmful gases in the drilling fluid mud. The vacuum degasser can also maintain the specific gravity of the mud, protect the sand pump and mud pump, and improve the treatment effect of subsequent equipment. Our vacuum degasser adopts the self-sufficient slurry suction method, so no additional slurry supply pump is required. The vacuum degasser can be equipped with an infrared liquid level monitoring system to ensure the continuity and safety of the equipment.

Features of Vacuum Degassers

1. It can quickly remove the gas in the air-invasion mud, restore the mud specific gravity, and stabilize the mud performance.

2. Self-priming device, no supply pump required.

3. Compact design, small footprint.

4. Free from corrosion, reducing the cost of repair and maintenance.

5. An optional infrared liquid level monitoring system enables automatic control of the equipment.

6. It can be used as a high-power stirrer.

7. The explosion-proof motor can be selected according to customer requirements.

8. Vacuum degassers with different degassing forms can be customized according to customer requirements.

9. With the same processing capacity, it consumes less power than similar products.

10. The unique structural design directly discharges the treated mud, so there is no need to equip a high-power centrifugal pump.

11. The combination of vacuum separation, crushing separation and microporous separation and other separation technologies has strong degassing ability.

12. The liquid level valve automatically adjusts the vacuum pressure.

13. The equipment is controlled by delay linkage mode, which is easy to operate.

Applications of Vacuum Degassers

Vacuum Degasser is adapted to get rid of various cut-in gases in the drilling fluids. Vacuum degasser is very important for returning mud gravity, stabilizing mud viscosity and reducing drilling cost. Therefore, it works as one type mud cleaning equipment. As it is placed after the shale shaker, so we call it second stage mud cleaning equipment in mud recycling system. At the same time vacuum degasser can be used as a heavy-power agitator.

1. The suction of the vacuum pump is used to make the mud enter the vacuum tank, and use it to draw the gas out of the vacuum tank. The vacuum pump plays two different roles here.

2. During the working process, the water ring vacuum pump is always in an isothermal state. It is suitable for the suction of flammable and explosive gases, with reliable safety performance.

3. Mud shoots through the windows of the rotor to the walls at high speed. The air bubbles in the mud are completely broken, and the degassing effect is good.

4. The main motor is offset, and the center of gravity of the whole machine is lowered.

5. The belt drive is adopted to avoid the complexity of the reduction mechanism.

6. The application of the steam-water separator will not cause water and gas to be discharged at the same time, so that the exhaust pipe will always be unblocked. In addition, water can also be circulated to the vacuum pump, saving water.

7. The suction pipe is inserted into the mud tank, and it can be used as a high-power agitator in the case of no air immersion in the mud.

Installation and Use of Vacuum Degasser

1. When installing, the site requirements are not very strict. As long as there is no obvious inclination.

2. Before starting, the end of the discharge pipe and the suction pipe should be immersed in the mud at the same time. Otherwise, it won't work.

3. A filter (40-60 mesh) should be installed at the air inlet of the exhaust pipe to prevent granular objects from entering the pump.

4. Before starting, first open the ball valve on the water supply line of the vacuum pump (you can also remove the water supply line of the vacuum pump and use a hose to supply water). Then unscrew the plug on the air-water separator and fill it with water. Stop when the water overflows from the overflow port, and screw on the plug. Finally, turn the coupling several turns by hand or with a pipe wrench to verify that there is no seizure or other damage in the pump before starting.

5. Before starting, you should first find out the direction of rotation of the motor. Both the vacuum pump and the main motor belt shield are marked with direction arrows, which should be consistent with the direction. Reverse operation is absolutely prohibited.

6. When the working water in the vacuum pump is supplied by the gas-water separator, it should be ensured that the temperature of the water is at most 150C-200C higher than the ambient temperature. Otherwise, new cold water should be replaced so that the vacuum pump can work normally.

7. After use, the water in the pump and the air-water separator must be drained.

8. Users should prepare the drain hose and exhaust hose by themselves.

Working Principle of Vacuum Degasser

The vacuum degasser uses the suction of the vacuum pump to create a negative pressure zone in the vacuum tank. Under the action of atmospheric pressure, the mud enters the hollow shaft of the rotor through the suction pipe, and then is thrown to the tank wall in the form of spray by the windows around the hollow shaft. The drilling fluid is separated into thin layers due to the collision and separation wheel. The air bubbles immersed in the mud then collapse and the gas escapes. Through the suction of the vacuum pump and the separation of the gas-water separator, the gas is discharged to a safe place through the exhaust pipe of the separator. The mud is discharged out of the tank by the impeller. Because the main motor starts first and the impeller connected with the motor is in a high-speed rotation state, so the mud can only enter the tank from the suction pipe and will not be sucked from the discharge pipe.

Price of Vacuum Degassers

The Degassers Price will change randomly with factors such as production cost, transportation cost, international situation, exchange rate, market supply and demand of raw materials. Sino Mechanical aims to provide you with high quality and best price Degassers. If you are looking for Degassers, please kindly contact us to get the latest Degassers price.

Vacuum Degassers Supplier

Sino Mechanical, as a Degassers manufacturer, has more than 20 years extensive experiences in the performance, application and cost-effective manufacturing of Degassers. We are global Degassers supplier. We offer a wide range of drilling equipment and have Degassers for sale. We also provide OEM services. We design, manufacture, and sell Degassers for your drilling applications. If you want to know latest Degassers price, don’t hesitate to contact us anytime. We will get back to you within 24 hours.

Specification

Technical Specifications of Vacuum Degassers

With the combination of vacuum separation, crushing separation and microporous separation, the degassing ability is strong.

The level valve automatically adjusts the vacuum pressure.

Using delay linkage control device, it is easy to operate.

As for ZCQ280-22 and ZCQ200-15 vacuum degasser, it does not need to be equipped with any other delivery pump and power can work. But the inlet and outlet liquid saliva seal is needed during installation. Otherwise it cannot work normally.

As for ZCQ270-5.5 vacuum degasser, It needs to be equipped with a separate delivery pump that can work normally.

As for ZCQ270-5.5 vacuum degasser, It does not need to seal the inlet and outlet. And it is easy to install on site.

Model | ZCQ280-22 | ZCQ200-15 | ZCQ270-5.5 |

Capacity(m³/h) | 280~320 | 200~240 | 270 |

Vacuum(mmHg) | 280~400 | 280~400 | 200~400 |

Vacuum Pump Power(kw) | 4 | 4 | 5.5 |

Main Motor Power(kw) | 22 | 15 | - |

Degasser Rotation Speed(min) | 980 | 980 | - |

Weight(kg) | 1700 | 1500 | 1700 |

External Dimension(mm) | 2350×1150×2477 | 2000×900×2000 | 2439×2226×1987 |