Description

Overview of Shale Shakers

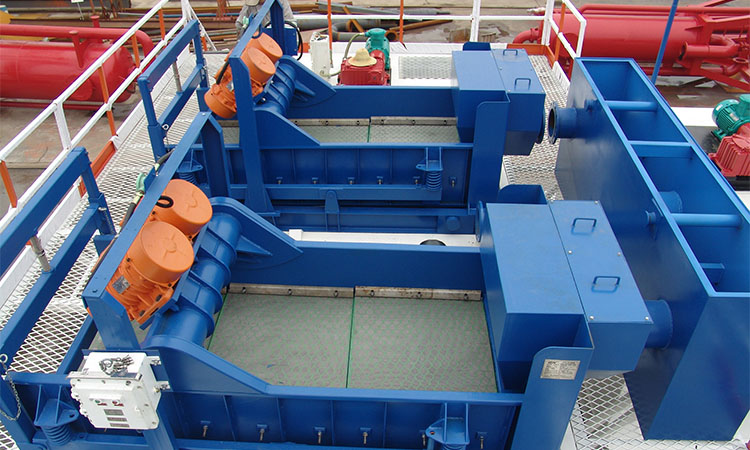

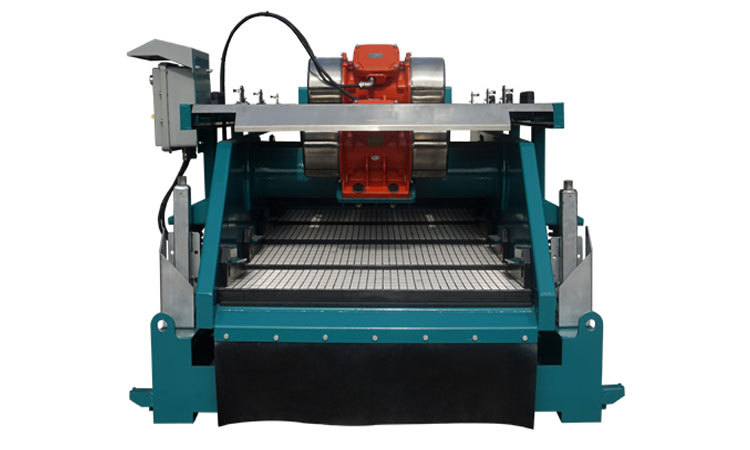

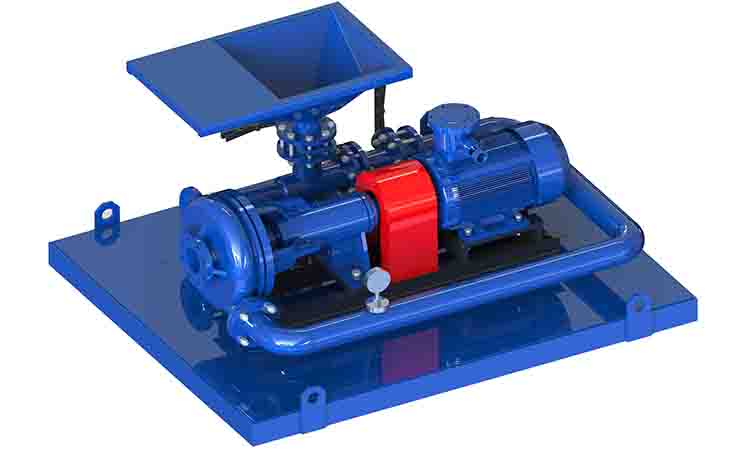

Drilling fluid shale shaker (shale shaker) is developed and launched by our company for primary solids control equipment for oil drilling. The drilling fluid shale shaker is mainly composed of a base, a screen box, a vibration spring, a vibration motor, and a feed logging tank. Our company can provide double or triple vibrating screens according to customer needs, and provide corresponding connecting manifolds. At the same time, the equipment can also be used as an underflow vibrating screen for a mud cleaner. The drilling fluid vibrating screen has the advantages of high vibration intensity, large screening area, adjustable screen box angle, compact structure, excellent performance, and high cost performance. Our vibrating screen has straight track and elliptical track, and can also be upgraded to negative pressure vibrating screen according to user requirements.

Features of Shale Shakers

1. Ajustable High G force for primary solids control or cuttings drying.

2. Heat treatment on complete shale shaker deck.

3. Vibrating Motor: IEC Ex, ATEX and UL Certified.

4. Electrical components: SIEMENS, Schneider Brand.

5. Shale Shaker Bottom Deck Material: Stainless Steel.

6. Wedge type design for easy and quick screen replacement.

7. Electric Shaker Deck angle adjustable while working.

Applications of Shale Shakers

The Shale Shakers is the first-level solid control equipment in the drilling fluid purification system. Shale Shakers are used to separate the large particle cuttings in the drilling fluid, and the treated drilling fluid containing smaller particles can enter the next level of solid control equipment to process.

The shale shaker is an important part of the mud recovery system, which helps to separate solids and liquids from drilling mud. It can realize the reuse of drilling fluid and reduce the impact on the environment.

Price of Shale Shakers

The Shale Shakers Price will change randomly with factors such as production cost, transportation cost, international situation, exchange rate, market supply and demand of raw materials. Sino Mechanical aims to provide you with high quality and best price Shale Shakers. If you are looking for Shale Shakers or Shale Shakers spares, please kindly contact us to get the latest Shale Shakers price.

Shale Shakers Supplier

Sino Mechanical, as a Shale Shakers manufacturer, has more than 20 years extensive experiences in the performance, application and cost-effective manufacturing of Shale Shakers. We are global Shale Shakers supplier. We offer a wide range of drilling equipment and have Shale Shakers for sale. We also provide OEM services. We design, manufacture, and sell Shale Shakers for your drilling applications. If you want to know latest Shale Shakers price, don’t hesitate to contact us anytime. We will get back to you within 24 hours.

Specification

Technical Specifications of Shale Shakers

Model | S752J-MDZJ | S594J-SHBJ | S595J-SDZJ | S706J-THBJ |

Vibration Mode | Linear Motion | |||

Capacity(m³/h) | 45(200GPM) | 140(616GPM) | 160(616GPM) | 140(616GPM) |

Vibration Motor(Kw) | 2×1.0 | 2×1.72 | 2×1.72 | 2×1.94 |

Screen Qty(Pcs) | 2 | 4 | 4 | 6 |

Screen Size | 750×900 | 585×1165×40 | 585×1165×40 | Up:750×900 |

Screen Area(m2) | 1.35 | 2.73 | 2.73 | Up: 2.03 |

Adjustable G Force | ≤7.5G | ≤7.3G | ||

Vibration Amplitude(mm) | 4.14~5.96 | 4.14~5.96 | 4.14~5.96 | 4.04~5.82 |

Deck Angle | +2° | -1~+5° | -1~+5° | -1~+5° |

Feeding Type | Top Box Feeder | Weir Feeder | Top | Weir Feeder |

Weir Height(mm) | 714 | 895 | 895 | 895 |

EX Standard | ExdIIBT4/IECEX/ATEX | |||

Weight(Kg) | 1041 | 1911 | 1911 | 2145 |

L×W×H(mm) | 1842x1670x1078 | 2990x2020x1437 | 3200*2020*1439 | 2749x2020x1574 |

Remarks | Above capacity only for reference, actual capacity will be various as per screen API No. and mud conditions | |||

The above specification and parameters for reference only. | ||||