Description

Overview of Mud Cleaner

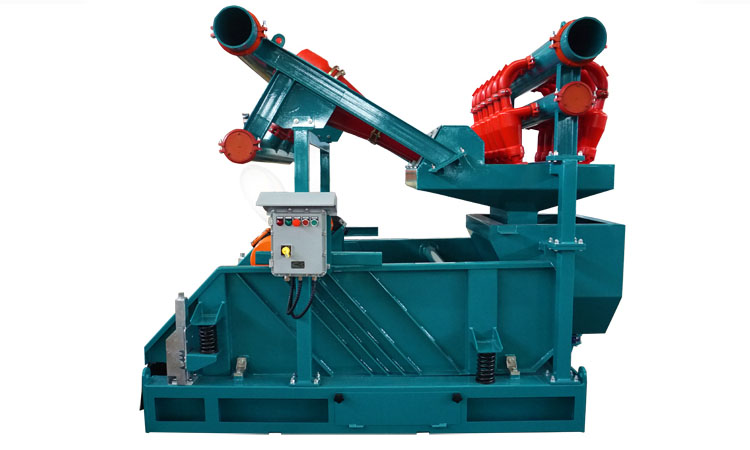

Drilling mud cleaner is also called Desander and Desilter assembly, oilfield mud cleaner, drilling fluids mud cleaners, which is the combination of desander, desilter and an underflow screen.

A mud is fed to the inlet of hydrocyclone to separate particles and the underflow passes to the fine mesh where in particles larger than barite are discarded and thrown away. It is the second and third phase cleaning equipment for a whole solids control system.

Features of Mud Cleaner

1.Desander & Desilter & Shale Shaker 3 in one unit mud cleaner for compact footprint.

2.Polyurethane Material hydrocyclone for long life.

3.Removable hydrocyclone assembly from mud cleaner skid for adjust to be a shale shaker.

4.Patent electric shaker deck angle adjustable while working, mechanical deck angle adjustment for backup application.

5. Both desander & desilter cone material is polyurethane (PU) for hard-wearing.

6. Italy brand motor, standard brand is OLI, Martin or Ital-Vibras motor as option

7. Max G force reaches to 7.5G, G force adjustable depending on drilling mud conditions

8. Heat treatment of shaker deck for steady working, Stainless Material for shaker deck bottom

9. Heavy anticorrosive painting on shaker service, 3 layer painting.

Wedge type screen and hook strip screen both available to suit client requirement.

10. Mechanical deck angle adjustment for steady and reliable performance.

11. Standard options: IECEX, ATEX, UL, DGMS, CE, Gost.

12. Top brand of electrical control panel, Siemens/Schneider brand main components

13. Composite material screen available for longer service life.

Applications of Mud Cleaner

The applicable new type is compact in structure, easy to use, easy to maintain, and reliable in operation. It can quickly remove harmful solid phases in drilling fluid, improve the performance of drilling fluid, and meet the requirements of the new high-pressure jet drilling technology.

Comparing with traditional separate Desander and Desilter, the mud cleaner has a higher cleaning function. The Underflow Screen equals another shale shaker which receives the waste out from the cyclone nozzle for additional processing. So that mud cleaner could recover more valuable drilling mud. Mud cleaner is the ideal device of the second class and the third class solid control to treat the drilling mud.

Price of Mud Cleaner

The Mud Cleaner Price will change randomly with factors such as production cost, transportation cost, international situation, exchange rate, market supply and demand of raw materials. Sino Mechanical aims to provide you with high quality and best price Mud Cleaner. If you are looking for Mud Cleaner, please kindly contact us to get the latest Mud Cleaner price.

Mud Cleaner Supplier

Sino Mechanical, as a Mud Cleaner manufacturer, has more than 20 years extensive experiences in the performance, application and cost-effective manufacturing of Mud Cleaner. We are global Mud Cleaner supplier. We offer a wide range of drilling equipment and have Mud Cleaner for sale. We also provide OEM services. We design, manufacture, and sell Mud Cleaner for your drilling applications. If you want to know latest Mud Cleaner price, don’t hesitate to contact us anytime. We will get back to you within 24 hours.

Specification

Technical Specifications of Mud Cleaner

Model | J594J-S1S8NJ | J594J-S2S12NJ | J594J-S3S16NJ | |

Capacity(m³/h) | 120(528GPM) | 240(1056GPM) | 360(1584GPM) | |

Desander Size(Inch) | 10 | 10 | 10 | |

Desander Qty(PCS) | 1 | 2 | 3 | |

Desilter Size(Inch) | 4 | 4 | 4 | |

Desilter Qty(PCS) | 8 | 12 | 16 | |

Working Pressure(Mpa) | 0.25~0.4 | 0.25~0.4 | 0.25~0.4 | |

Inlet Size (Inch) | 6 | |||

Outlet Size (Inch) | 8 | |||

Bottom Shaker Specs. | Shaker Model | S594J | J594J | J594J |

Vibration Mode | Linear Motion | |||

Motor(Kw) | 2×1.72 | |||

Screen Qty(Pcs) | 4 | 4 | 4 | |

Screen Size: (mm) | 585×1165 | 585×1165 | 585×1165 | |

Screen Area(m2) | 2.73 | 2.73 | 2.73 | |

Adjust G Force | ≤7.5G | ≤7.5G | ≤7.5G | |

Vibration Amplitude(mm) | 4.14~5.96 | 4.14~5.96 | 4.14~5.96 | |

Deck Angle Range | -1~+5° | |||

EX Standard | ExdIIBT4/IECEX/ATEX | |||

Weight | 1930 | 2285 | 2378 | |

Dimension(mm) | 2462x2042x2147 | 2707×2042×2147 | 2707×2042×2147 | |

The above specification and parameters for reference only. | ||||