Description

Overview of Mixing Hoppers

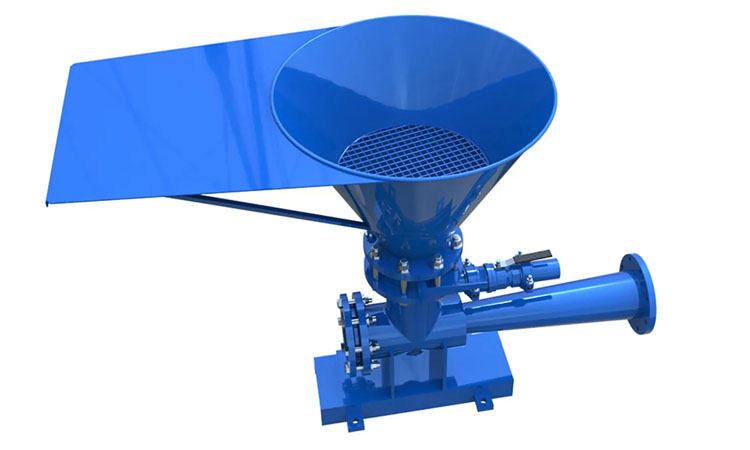

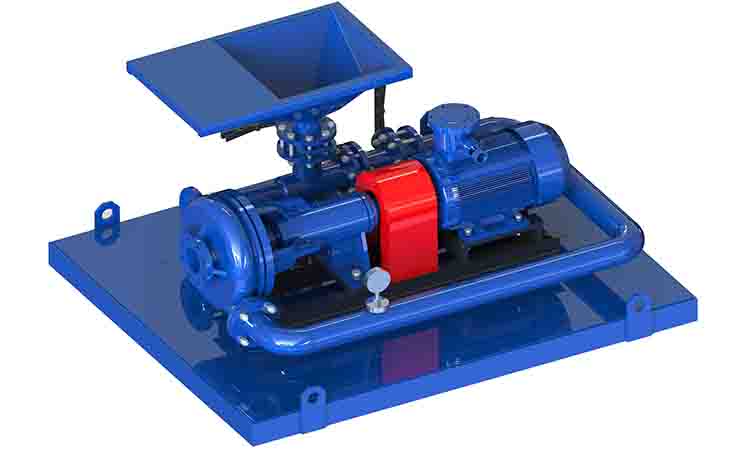

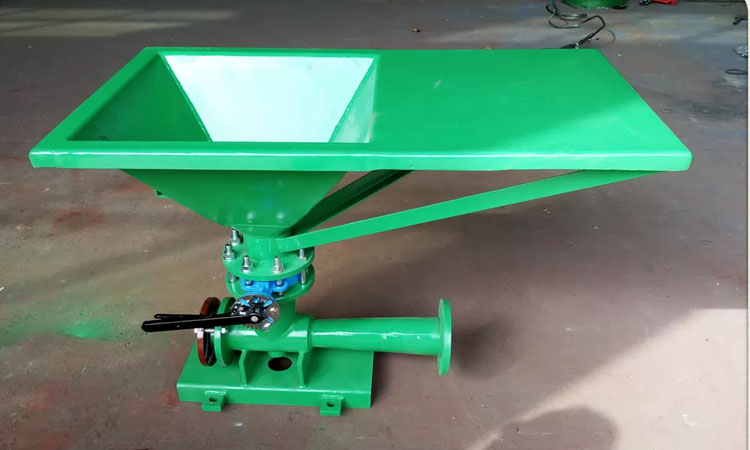

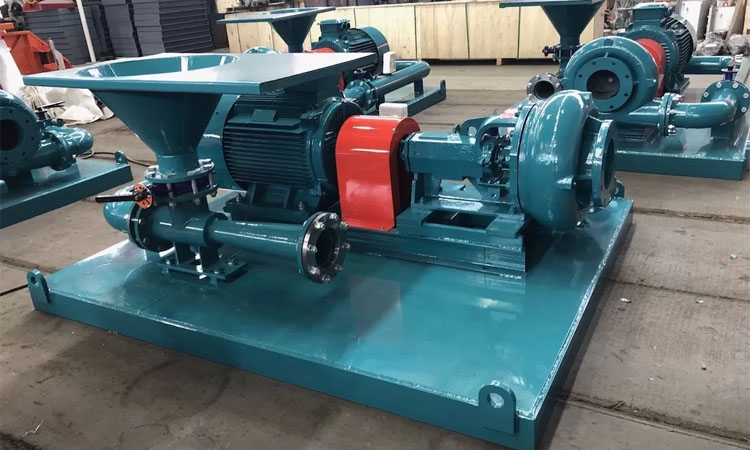

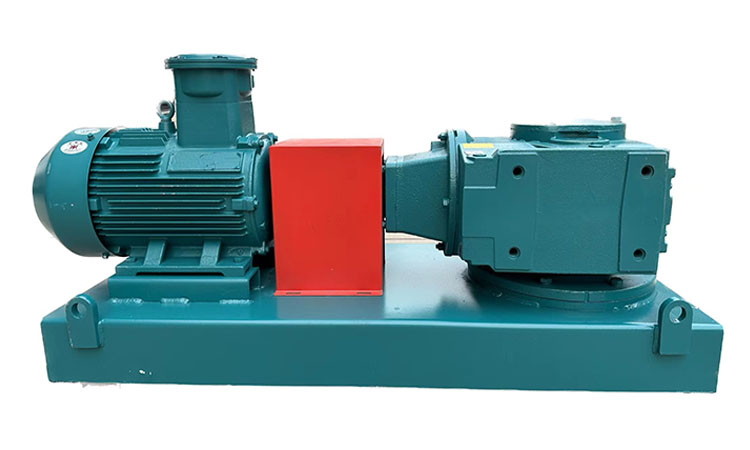

The drilling mud mixing hopper is a mud mixing funnel. Drilling mud mixing hopper has main components include nozzle, mixing chamber, venturi tube, feeding hopper, butterfly valve, sand pump or shear pump. Drilling mud mixing hopper is usually applied to oil drilling solids control.

One sand pump and one mud mixing hopper are installed on a base with pipe valves. It has a more excellent operation performance if being matched with a shear pump.

Drilling mud mixing hopper is mainly used to configure drilling fluid, change drilling fluid density, viscosity, water loss, etc. It is one of the special oilfield equipment for weighting drilling fluid. The drilling mud mixing hopper is equipped with sand pumps and pipelines to form a jet mixing device.

Features of Mixing Hoppers

1. Big hopper inlet diameter, high mixing capacity, Wide range of material applicability

2. Compact structure, less space needed and easy to move

3. Special spraying design, guarantee mixing time and performance

4. Ex motor and electrical components, mechanical seal pumps, long service life

Applications of Mixing Hoppers

Mixing Hoppers are used to prepare and increase drilling fluids weight by adding and mixing bentonite, changing fluid density, viscosity and dehydration.

Price of Mixing Hoppers

The Mixing Hoppers Price will change randomly with factors such as production cost, transportation cost, international situation, exchange rate, market supply and demand of raw materials. Sino Mechanical aims to provide you with high quality and best price Mixing Hoppers. If you are looking for Mixing Hoppers, please kindly contact us to get the latest Mixing Hoppers price.

Mixing Hoppers Supplier

Sino Mechanical, as a Mixing Hoppers manufacturer, has more than 20 years extensive experiences in the performance, application and cost-effective manufacturing of Mixing Hoppers. We are global Mixing Hoppers supplier. We offer a wide range of drilling equipment and have Mixing Hoppers for sale. We also provide OEM services. We design, manufacture, and sell Mixing Hoppers for your drilling applications. If you want to know latest Mixing Hoppers price, don’t hesitate to contact us anytime. We will get back to you within 24 hours.

Specification

Technical Specifications of Mixing Hoppers

MODEL | CAPACITY(M3/H) | PRESSURE (MPA) | MOTOR (KW) | INLET (INCH) | OUTLET (INCH) | WEIGHT (KG) | DIMENSION L×W×H(MM) |

LH-750B | 320(1408GPM) | 0.25~0.4 | 75(100HP) | 8 | 6 | 1785 | 2200×1840×1150 |

LH-550B | 272(1200GPM) | 55(75HP) | 8 | 6 | 1675 | 2200×1840×1100 | |

LH-450B | 200(880GPM) | 45(60HP) | 6 | 6 | 1475 | 2200×1840×1135 | |

LH-370B | 150(660GPM) | 37(50HP) | 6 | 6 | 1460 | 2200×1840×1135 | |

LH-300B | 120(528GPM) | 30(40HP) | 5 | 6 | 1380 | 2200×1840×1100 | |

LH-220B | 90(400GPM) | 22(30HP) | 5 | 4 | 1167 | 1850×1540×1000 | |

LH-185B | 65(286GPM) | 18.5(25HP) | 4 | 4 | 1147 | 1850×1540×1030 | |

LH-150B | 55(242GPM) | 15(20HP) | 4 | 4 | 970 | ||

LH-110B | 45(200GPM) | 11(15HP) | 4 | 4 | 950 | ||

Remarks | Electric control cabinet should be quoted separately, weight & dimension don't included control cabinet | ||||||

The above specification and parameters for reference only. | |||||||

Model | Pressure | Capacity | Nozzle | Inlet | Outlet | Weight | Dimension: L×W×H |

LDSB | 0.25~0.4Mpa | 500-1500 GPM (113-340m3/h) | 40mm | 6 Inch | 6 Inch | 174Kg | 1100×680×949mm |

LDMB | 200-500 GPM (45-113m3/h) | 20mm | 4 Inch | 4 Inch | 113Kg | 850×570×851mm | |

The above specification and parameters for reference only. | |||||||