Description

Overview of Decanter Centrifuge

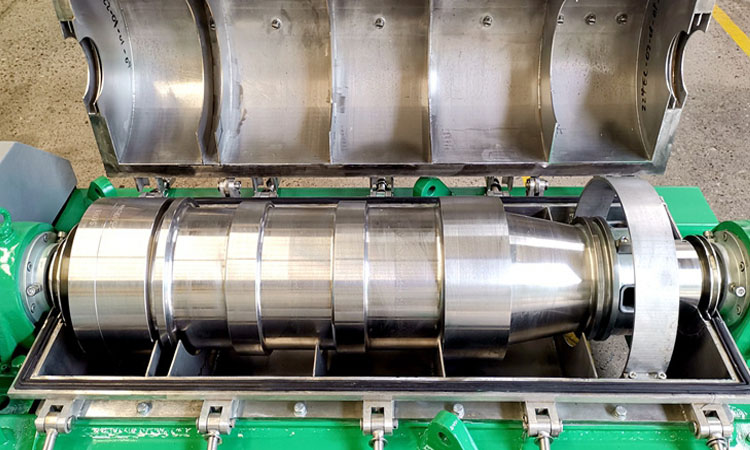

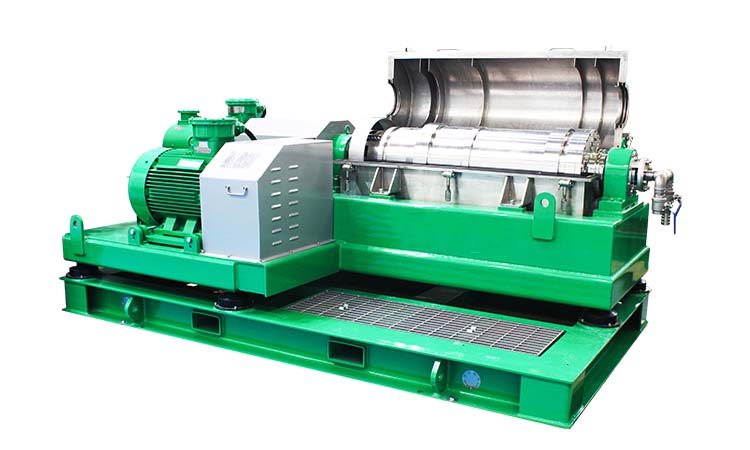

Drilling fluid Decanter Centrifuge is composed of frame, cover, main bearing, drum, screw, differential, drive system, control system and safety protection system. The drum and the screw rotate at a high speed in the same direction at a differential speed, and the material enters the screw inner cylinder through the feeding pipe, and enters the drum from the feeding port. Under the action of centrifugal force, the heavy solid material is deposited on the drum wall to form a sediment layer, and the screw continuously pushes the deposited solid material to the cone end of the drum. It is discharged out of the machine through the slag discharge port. The lighter liquid phase material forms an inner liquid ring, continuously overflows the drum from the overflow port at the large end of the drum. And it is discharged out of the machine through the liquid discharge port.

It is mainly used to recover barite in drilling mud. Decanter Centrifuge can remove fine solids, reduce the solid content of drilling fluid, control the density and viscosity of drilling fluid, and ensure the performance of drilling fluid. Decanter Centrifuge plays an important role in fast drilling.

Features of Decanter Centrifuge

1. High G Force up to max 3000. Big Volume Design.

2. Bowl Material Duplex Stainless Steel 2205 made from centrifugal casting.

3. Conveyor Wear Surface: Tungsten carbide tiles .The life is much longer than hard surface. And all tiles is interchangeable for easy maintenance.

4. Pressurized Explosion Proof with PLC and HMI control for automatically operation.

5. All the bearings for the centrifuge are SKF brand premium bearings.

Applications of Decanter Centrifuge

1. Solid phase dehydration: remove the moisture of solid particles in the material.

2. Liquid phase clarification: remove the solid particles in the suspension to obtain a clarified liquid.

3. Particle classification: Separate the solid particles with larger specific gravity than the separation liquid from those with small particles.

Price of Decanter Centrifuge

The Decanter Centrifuge Price will change randomly with factors such as production cost, transportation cost, international situation, exchange rate, market supply and demand of raw materials. Sino Mechanical aims to provide you with high quality and best price Decanter Centrifuge. If you are looking for Decanter Centrifuge, please kindly contact us to get the latest Decanter Centrifuge price.

Decanter Centrifuge Supplier

Sino Mechanical, as a Decanter Centrifuge manufacturer, has more than 20 years extensive experiences in the performance, application and cost-effective manufacturing of Decanter Centrifuge. We are global Decanter Centrifuge supplier. We offer a wide range of drilling equipment and have Decanter Centrifuge for sale. We also provide OEM services. We design, manufacture, and sell Decanter Centrifuge for your drilling applications. If you want to know latest Decanter Centrifuge price, don’t hesitate to contact us anytime. We will get back to you within 24 hours.

Specification

Technical Specifications of Decanter Centrifuge

Model | LW363C | LW363C-V | LW453C-V | LW553C-V |

Bowl Diameter | 360mm(14inch) | 360mm(14inch) | 450mm(18inch) | 550mm(22inch) |

Bowl Length | 1271mm(50inch) | 1271mm(50inch) | 1540mm(61inch) | 1800mm(71inch) |

Max. Capacity | 200GPM(45m3/h) | 200GPM(45m3/h) | 352GPM(80m3/h) | 484GPM(110M3/h) |

Effective Capacity | 132GPM(30m3/h) | 132GPM(30m3/h) | 264GPM(60m3/h) | 400GPM(90m3/h) |

Max Bowl Speed | 3900RPM | 3900RPM | 3200RPM | 3000PRM |

Typical Bowl | 3200RPM | 0~3200RPM | 0~2800RPM | 0~2500RPM |

Max G-Force | 3063 | 3063 | 2578 | 2719 |

Typical G-Force | 2062 | 0~2062 | 0~1973 | 0~1888 |

Separation point | 2~5µm | 2~5μm | 2~5µm | 2~5μm |

Differential Speed | 40 | 0~40 | 0~35 | 0~45 |

Gearbox Torch | 3500N.M | 3500N.M | 7500N.M | 12000N.M |

Gear Box Ration | 57:1 | 57:1 | 57:1 | 35:1 |

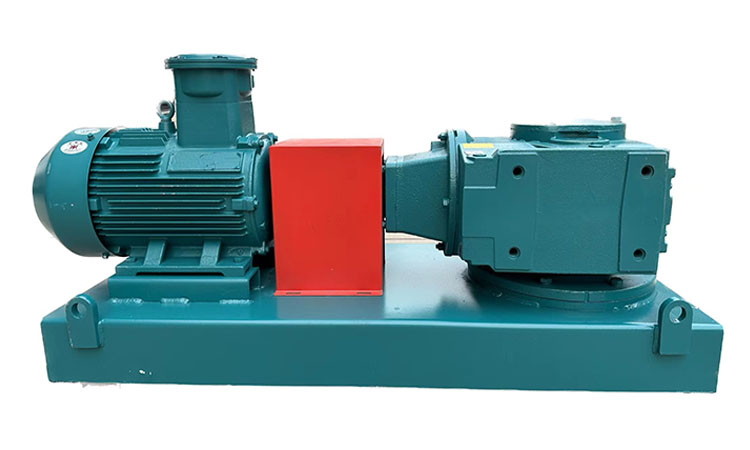

Main Drive Motor | 37KW(50HP) | 37KW(50HP) | 55KW(75HP) | 90KW(120HP) |

Back Drive Motor | 11KW(15HP) | 11KW(15HP) | 22KW(30HP) | 37KW(50HP) |

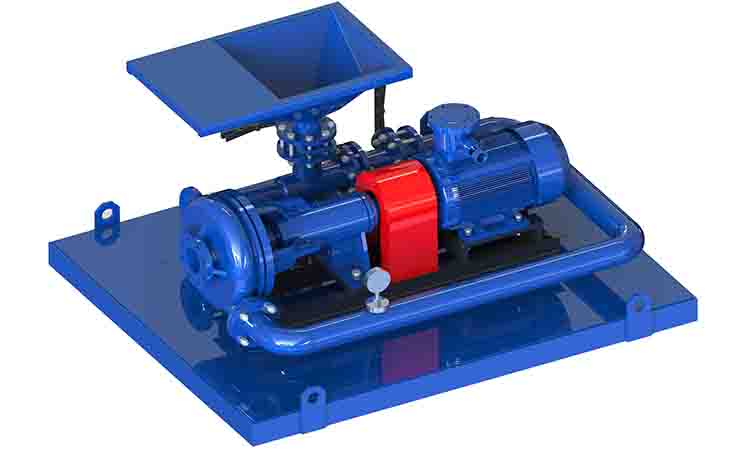

Recommend Pump | 7.5KW(10HP) | 7.5KW(10HP) | 15KW(20HP) | 22KW(30HP) |

EX Standard | ExdIIBt4 / IEC EX/ ATEX | |||

Electric Carbinet | Exd Standard | PLC+Positive Pressurized | ||

Weight | 3500KG | 3400KG | 4580KG | 5840KG |

Dimension | 3305x1638x1277mm | 3305x1638x1277mm | 3824x1798x1317 | 4293x1978x1381 |