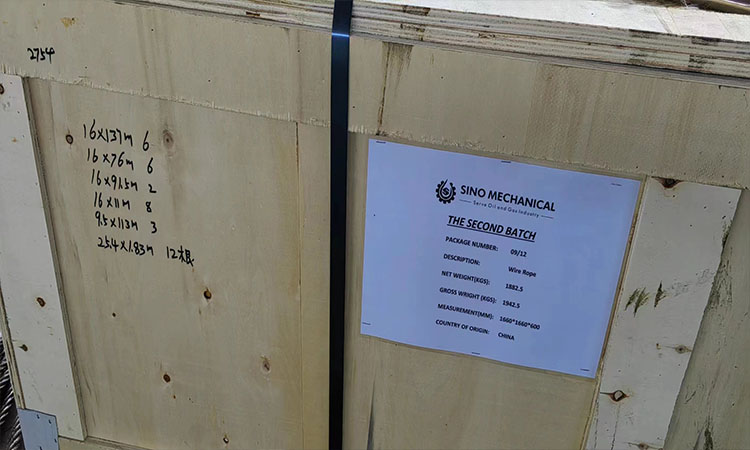

Sino Mechanical slings, wire rope ship to European customers

Sino Mechanical Equipment has completed the production and inspection of slings and wire ropes and is preparing to ship them to European drilling customers.

Drilling wire rope is an important tool used in the oil drilling industry. It undertakes the important tasks of lowering drill bits and other drilling tools to the wellhead and lifting drilling tools.

Slings

Sling is the connection between the crane or the main body of the hoisted object and the hoisted object. It is also a general term covering slings and spreaders. Slings mainly include metal slings and synthetic fiber slings. Among them, metal slings mainly include wire rope slings, chain slings, shackles, hooks, hanging (clamp) clamps, magnetic slings, etc. Synthetic fiber slings mainly include rope and belt slings produced from nylon, polypropylene, polyester, and high-strength high-modulus polyethylene fibers.

Wire rope

Wire rope is a flexible material made of many thin steel wires twisted together. It is widely used in various industrial and civil fields such as hoisting, lifting, traction and support. Steel wire ropes offer excellent performance in a variety of applications due to their high strength, wear resistance, and corrosion resistance.

The production process of steel wire rope

The production process of steel wire rope usually includes the following steps: first, you need to select a suitable material, usually using high-strength carbon steel wire; then, multiple steel wires are woven or twisted together in a certain order and method to form a thicker wire rope. of twisted strands; next, multiple twisted strands are braided or twisted together again to form a more complex structure, thus obtaining a thicker wire rope; finally, as needed, multiple thicker wire ropes can be braided Or twisted together to form a larger diameter wire rope.

The structure of a wire rope determines its performance. Typically, the more complex the structure of a wire rope, the greater its strength and load-bearing capacity. At the same time, appropriate structure can also improve the flexibility and durability of the wire rope. In addition to ordinary structural steel wire ropes, there are also some special structural steel wire ropes, such as parallel knots, ring-strand strands, embedded hole strands, etc., which have better adaptability and performance under special conditions.

The application of wire ropes

Wire ropes are widely used in various industries. On construction sites, wire ropes are used as components of hoisting machinery and tower cranes to safely and reliably lift and carry heavy objects. In marine engineering, wire ropes play an important role in oil well communication, offshore platform anchoring, and ship towing power. In transportation, steel wire ropes are used to make cable cars, baskets and various ropeway systems. In agriculture and fishery, wire ropes can be used for tractor pulling, fishing net dragging, etc.

Selection of steel wire ropes for oil drilling cranes

The steel wire rope used for pulling the sucker rod and oil pipe

The steel wire rope used for pulling the sucker rod and oil pipe will choose a compacted strand steel wire rope, and the rope core will be a fibrous or metal core line contact wire rope or a rotation-resistant wire rope. When the well depth is shallow, the 6x25F or 6x26WS wire rope is usually chosen.

Sand fishing wire rope

In the oil drilling process, the sand fishing operation also requires the use of crane wire ropes. In order to ensure safety and avoid accidents such as detachment of the drilling rope from the wire rope of the sand fishing drum connected to it, a 6x7 line contact wire rope is generally selected to increase the breaking tension of the entire wire rope and have good impact resistance and structural stability.

Drilling wire rope

The exploitation of oil resources is inseparable from drilling platforms and oil production platforms. Among them, the drilling ropes used in drilling platforms are crane wire ropes that form part of the operating system of oil drilling rigs and derricks. In order to avoid being affected by the corrosive environment around the oil well, compacted strand wire ropes are generally used, and the rope core is made of fiber or metal core. Line contact wire rope.

Derrick installation winch rope

The application of floor-standing multi-rope winches has promoted the use and development of multi-rope lifting steel structure derricks. Generally, 6x26WS-IWRC, 6x31WS-IWRC, 6x36WS-IWRC and other types of line contact wire ropes are used.

Pumping unit donkey head rope

Oil production operation is one of the main types of operations that consumes wire ropes from oil drilling cranes, and a large amount of wire ropes are required. In oil production operations, most of the crane wire ropes used are sucker rods and oil pipe traction ropes. These wire ropes mainly play a connecting role between the pumping head and the sucker rod. Since the oil pumping unit will generate large pressure during operation, the steel wire rope used in oil production operations has higher requirements for strength and wear resistance. Point contact wire ropes or anti-rotation wire ropes with metal rope cores are usually used.

Shallow sea anchor ropes, mast-type derrick taut ropes

Shallow sea derricks have higher corrosion resistance requirements for crane wire ropes, so point contact wire ropes with metal rope cores are generally selected.

Drilling wire rope is a special-purpose wire rope. With the continuous advancement of wire rope design technology and the continuous development of drilling rig manufacturing technology, Sino Mechanical Equipment is also constantly updating the manufacturing technology of wire rope to meet the changing drilling needs.