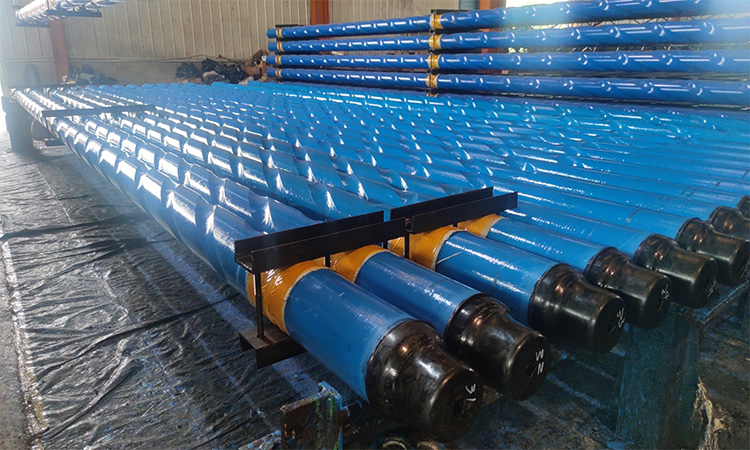

Sino Mechanical drill collars ship to Middle East customers

Sino Mechanical Equipment has completed the production and inspection of drill collars and is preparing to ship them to drilling customers in the Middle East.

The specifications of this drill collar are as bellow:

Spiral drill collar 8"×2-13/16" 6-5/8REG material 4145HM

Spiral drill collar 6-1/2"×2-13/16" NC50 material 4145HM

Spiral drill collar 4-3/4"×2" NC38 material 4145HM

The drill collar is located at the lowermost part of the drill string and is the main component of the lower drill tool assembly. Its main features are large wall thickness, large gravity and stiffness. In order to facilitate drilling work, elevator grooves and slip grooves can be processed on the outer surface of the internal thread of the drill collar. Drill collar implementation standard API Spec 7-1.

The drill collar is connected to the drill pipe with a threaded thread on the top and the drill bit on the bottom. Its main function is to use its own weight to provide drilling pressure for the drill bit to break the rock and achieve drilling. In addition, since the drill collar itself is relatively rigid, it can be combined with a stabilizer to form a rigid drill string, which can prevent the lower drill string from bending during drilling and avoid well deviation.

Classification of drill collars

Drill collars are generally divided into three types: spiral drill collars, non-magnetic drill collars, and Integral drill collars.

1) The integral drill collar is a smooth thick-walled round tube with connecting threads processed on both ends.

(2) Spiral drill collars are processed with spiral grooves on the outer cylindrical surface of round drill collars to reduce the contact area with the well wall, which can effectively prevent pressure differential stuck.

(3) Non-magnetic drill collars are mainly used for monitoring during oil drilling, and their structures are the same as integral drill collars. Non-magnetic drill collars are made of materials with very low magnetic permeability such as N1310 low carbon alloy steel. The material is forged through strict chemical composition analysis. The material's mechanical properties have been tested to ensure that the hardness, toughness, impact value and corrosion resistance meet standards, and it has good low magnetic permeability and good machining performance.

The main function of drill collars

1) Apply drilling pressure to the drill bit;

(2) Ensure the necessary strength under compression conditions;

(3) Reduce the vibration, swing, and beating of the drill bit to make the drill bit work smoothly;

(4) Control well deviation.

Precautions for cleaning spiral oil drill collar parts

1. Hydraulic parts cleaning should be carried out on a special cleaning table. It cannot be cleaned anywhere. It should be kept away from pollution sources and the cleaning site should be clean.

2. The cleaning fluid of the long spiral drilling rig is allowed to use kerosene, gasoline and hydraulic oil with the same grade as the working oil of the hydraulic system.

3. Cleaned parts are not allowed to be wiped with cotton, linen, silk or chemical fiber fabrics to prevent fallen fibers from contaminating the system.

4. After cleaning, the parts of the long auger drill are not allowed to be placed directly on the ground, cement floor, floor, bench and assembly workbench. They should be placed in a container with a lid and injected with clean hydraulic oil.

5. It is best to take protective measures for cleaned parts to keep them away from oxidative pollution.

Drill collar is a type of petroleum drilling tools. Petroleum drilling tools include drill collars, drill pipes, adapters, centralizers, etc. Petroleum drilling tool products generally refer to special pipes used for formation drilling and mining in the oil and natural gas mining industry. Oil drilling tools Tools are irreplaceable high-tech tool products in the petroleum industry. They are consumable and are widely used in deep underground operations such as oil exploration, geological exploration and deep well excavation.

Sino Mechanical Equipment is a high-tech enterprise that provides various drilling tools for the exploration and development of oil, natural gas and other oil and gas energy. It is committed to developing and providing high-quality oil drilling equipment to meet the changing needs of customers and contribute more to the development of the petroleum industry.