Operation and maintenance of Sino Mechanical XQ114/6YB hydraulic power tongs

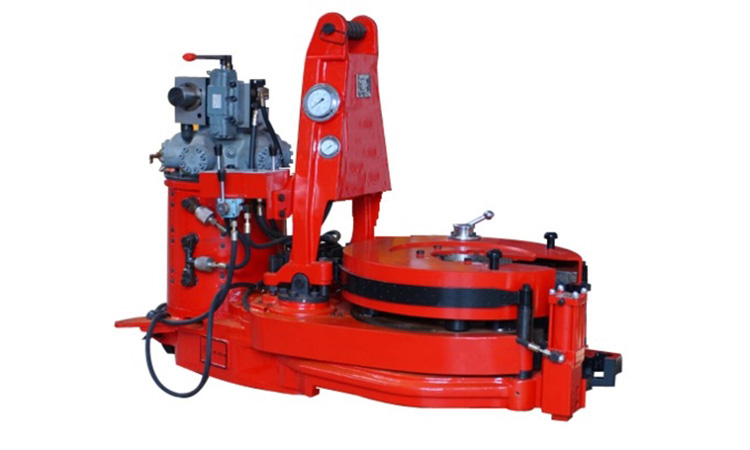

Sino Mechanical XQ114/6YB hydraulic power tongs are medium-sized power tongs used for loading and unloading oil pipe threads in oilfield well repair operations.

Operation instructions for Sino Mechanical XQ114/6YB hydraulic power tongs

1. Replacement of jaw plates

The jaw plates of the main tong and back tong of this power tong are both free-style installed, that is, the jaw plates can be loaded and unloaded from the center space. Positioning screws (Z6-81) and (B6-25) are provided on both sides of the jaw plate frame opening of the main tong and back tong to limit the jaw plates (Z6-79) and (B6-31) so that they do not fall out during transportation. When the jaw plates need to be removed, start the main tong and back tong to expose the positioning screws from the tong head opening, withdraw the main tong positioning screws (Z6-81), and remove or load the main tong jaw plate assembly from the center of the tong head. The specification number of the newly installed jaw plate must be consistent with the diameter of the clamping column. Withdraw the back-tong positioning screw (B6-25), remove or install the back-tong jaw plate assembly from the back-tong opening, and the specification number of the newly installed jaw plate must be consistent with the diameter of the clamping coupling.

2. Gear shifting operation

Operate the manual reversing valve (Z6-33) and press down the fork shaft (Z6-90) to shift to high gear. Operate the manual reversing valve (Z6-33) and lift up the fork shaft (Z6-90) to shift to low gear. The gear shifting operation must be performed at a slower speed to prevent damage to the gears.

3. Loading and unloading buckle operation

Loading buckle operation

When the main and back tong heads are aligned with the opening, move the reset knobs (Z6-49) and (B6-3) to the loading buckle direction, push the power tong to the pipe column, operate the manual reversing valve (Z6-33) to rotate the main tong in the loading buckle direction, and perform loading buckle. After loading buckle, operate the manual reversing valve (Z6-33) to reverse the main tong, align the main and back tong heads with the openings, and then remove the power tong from the pipe column. That is, an unloading buckle operation is completed.

Unloading buckle operation

When the main and back tong heads are aligned with the openings, move the reset knobs (Z649) and (B6-3) to the unloading buckle direction, push the power tong to the pipe column, operate the manual reversing valve (Z6-33) to rotate the main tong in the unloading buckle direction, and perform unloading buckle. After unloading the buckle, operate the manual reversing valve (Z6-33) to reverse the main tong, align the main tong and back tong heads with the openings respectively, and then remove the power tong from the pipe column. This completes an unloading buckle operation.

4. Replace the tong teeth

Use a screwdriver to push the tong tooth stop pin (Z6-74) on the jaw plate to remove the tong teeth

The tong teeth are available in large arc and small arc types. The applicable size is marked on the back of the tong teeth. The large arc tong teeth are suitable for clamping 89~141.5 (3 1/2"~4 1/2") pipes or couplings. The small arc tong teeth are suitable for clamping 73~78 (27/8"~3") pipes or couplings.

Sino Mechanical XQ114/6YB hydraulic power tongs maintenance and lubrication

1. After each handling, clean the main and back tongs with kerosene or diesel, and fill the grease nozzles of the machine body with butter. 2. After cleaning the tongs, grease the jaws, jaw frame, and open gears.

3. If the jaws do not extend due to insufficient braking force, the braking pressure needs to be adjusted, and the bolts with holes (Z654) need to be tightened slightly. Be careful not to tighten them too much to overheat the friction plate.

4. After each use, check the tongs. If there is water accumulation or sludge, it must be removed in time. 5. After each use, the rotating pins must be filled with oil.

6. Steam cleaning of the tongs is not allowed to prevent the bearings from losing oil or getting water and being damaged.

7. The hydraulic oil temperature must not exceed 65℃. Overheating will cause the hydraulic system seal to fail.

8. The hydraulic oil must be kept clean and the oil filter must be kept filtering oil normally. If the oil is dirty, it needs to be replaced in time.

9. Hydraulic oil selection:

(1) YC-N46 low-condensation hydraulic oil, suitable for ambient temperature -20℃~+40℃;

(2) YB-N46 anti-wear hydraulic oil, suitable for ambient temperature -10℃~+40℃;

(3) YA-N46 ordinary hydraulic oil, suitable for ambient temperature

0℃~+40℃

Supplier of Hydraulic Power Tongs

Sino Mechanical Equipment is a supplier of Hydraulic Power Tongs, providing various types of oil drilling and well repair equipment, such as: hydraulic power tongs, Traveling Block and Hook Blocks, Wire Ropes, Deadline Anchor, casing Elevator / Spiders, Mud pumps, Drilling Drawworks, etc. Sino Mechanical Equipment is located in Shengli Oilfield, the second largest oilfield in China. It has a long experience in producing oil drilling equipment and provides high-quality oil drilling equipment and services to the world.