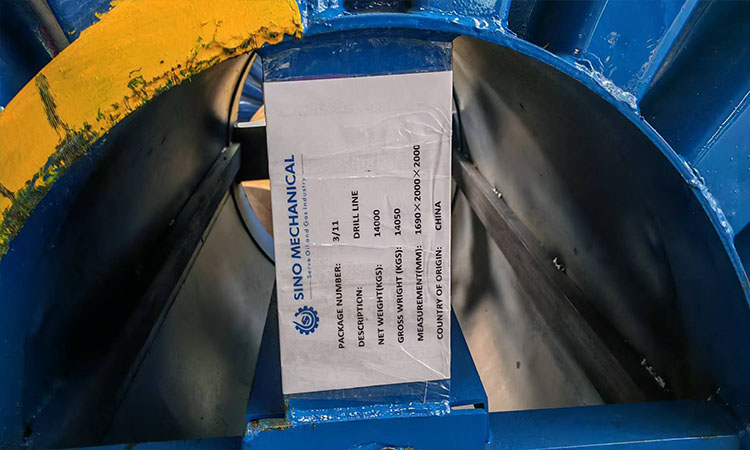

Oil drilling wire rope supplied by Sino Mechanical Equipment ready for shipment

1.Wire ropes for oil drilling provided by Sino Mechanical Equipment has the following characteristics:

1) High strength and high load-bearing capacity

Material and structure: Made of high-strength steel wire (such as high carbon steel or alloy steel), usually 6×19, 6×37 or 8×19 structure (number of strands × number of steel wires per strand) to balance flexibility and strength.

Tensile strength: Generally required to be 1770 MPa~2160 MPa, or even higher, to withstand the weight of drilling tools and dynamic impact loads.

2) Wear resistance and extrusion resistance

Surface treatment: The surface of the steel wire rope may be galvanized or coated with polymer to enhance wear resistance.

Structural design: Compacted strand or surface contact steel wire rope is used to reduce friction between steel wires and improve extrusion resistance (especially at pulleys and drums).

3) Fatigue resistance and impact resistance

Flexible design: By optimizing the twist direction (such as right-handed twist) and strand structure, bending stress is reduced and fatigue life is extended.

Dynamic load adaptability: Need to withstand vibration, drilling and other impact loads during drilling.

4) Corrosion resistance

Environmental challenges: Contact with corrosive media such as drilling mud, brine, hydrogen sulfide (H₂S).

Protective measures: Galvanized steel wire rope or stainless steel wire (such as 316 material), plastic coated steel wire rope (such as nylon coating) is used under special working conditions.

5) Stability and anti-rotation

Multi-strand non-rotating structure: such as 18×7, 35×7 multi-strand steel wire rope, to prevent the steel wire rope from rotating when hanging heavy objects, ensuring safe operation.

6) Temperature adaptability

High temperature resistance: Some deep wells or high-temperature wells need to withstand environments above 120°C, and the materials need to undergo special heat treatment.

2. Wire rope for oil drilling is a key component in drilling equipment. It is mainly used for lifting, hanging and pulling drilling tools (such as drill pipes, drill collars, casing, etc.). It needs to have high strength, wear resistance, corrosion resistance and fatigue resistance. The following is a detailed introduction to wire rope for oil drilling:

Main types

Drilling wire rope

6×19 structure: such as 6×19S, the outer layer of steel wire is thicker and has good wear resistance. It is often used for light to medium drilling operations.

6×36 structure: such as 6×36WS (composite structure), it has higher flexibility and strong fatigue resistance, and is suitable for deep or ultra-deep well operations.

8×19 structure: such as 8×19S, the multi-strand design improves flexibility and is suitable for frequent bending conditions.

Casing Wire Rope

Specially used for lowering and hanging casing, it needs to bear huge static loads, and usually adopts high-strength independent wire rope core (IWRC) structure.

Sucker Rod Wire Rope

Used for pumping units (knock-down units), it needs to resist reciprocating bending and corrosion.

3. Core Material and Structure

Wire Material:

High carbon steel (such as AISI 1080) or alloy steel (such as galvanized, zinc-aluminum alloy coating), enhanced tensile strength and corrosion resistance.

Stainless steel wire may be used in special environments (such as offshore platforms).

Rope Core Type:

Fiber Core (FC): Good flexibility, but poor high temperature resistance, suitable for light operations.

Steel Core (IWRC/WSC): High load-bearing capacity, anti-extrusion, suitable for heavy loads and deep wells.

Outer Wire Treatment:

Galvanized, phosphating or sprayed with wear-resistant layer to extend service life.

4. Key performance requirements

High strength: tensile strength is usually 1770MPa~2160MPa (such as API Spec 9A standard).

Fatigue resistance: needs to withstand high-frequency vibration and bending during drilling.

Corrosion resistance: resists corrosive media such as mud, brine, H₂S.

Abrasion resistance: prevents damage caused by friction with pulleys and drums.

5. International standards and specifications

API Spec 9A: General standard for the petroleum industry, covering wire rope design, testing and acceptance requirements.

ISO 10425: Relevant specifications of the International Organization for Standardization.

6. Common causes of failure

Fatigue fracture: Frequent bending causes micro cracks in the wire to expand.

Wear: Friction with the derrick pulley causes the outer layer of the wire to become thinner.

Corrosion: Acidic environment or brine erodes the surface of the wire.

Overload: Sudden fracture caused by exceeding the rated load.

7. Maintenance and replacement recommendations

Regular inspection: Use magnetic particle inspection or visual inspection to check for surface wear and broken wires (if the API stipulates that the number of broken wires exceeds the standard, it must be replaced).

Lubrication and maintenance: Keep the wire rope internally lubricated to reduce friction and corrosion.

Proper storage: Avoid humid environments to prevent rust.

8. Selection points

Choose a structure based on well depth, load, and environment (onshore/offshore) (such as 6×36WS for deep wells).

Galvanized or alloy coatings are preferred to extend life.

Ensure compliance with API or ISO certification to ensure safety.

If more specific parameters (such as diameter, breaking tension, etc.) are required, they can be further matched in combination with the drilling equipment model.

9. Supplier of oil drilling wire ropes

Sino Mechanical Equipment is located in Shengli Oilfield, China. It has been providing drilling equipment and drilling tools to Chinese and global drillers for decades and is a high-quality supplier of oil drilling wire ropes.