Mud pumps shipped to European customers

Mud pumps shipped to European customers

The mud pump is an important part of the drilling equipment. It refers to the machine that transports mud or water and other flushing fluids into the borehole during the drilling process.

In commonly used positive circulation drilling, it is to send the surface flushing medium, clear water, mud or polymer flushing liquid, under a certain pressure, directly to the bottom of the drill bit through the high-pressure hose, faucet and the center hole of the drill pipe string to achieve The purpose is to cool the drill bit, remove the cut cuttings and transport them to the surface.

Traditionally, we divide mud pumps into two parts: the liquid end and the power end. The power end is used to transmit power and convert motion modes and speeds, and the liquid end provides appropriate gathering force; the liquid end is used to convert mechanical energy into liquid internal energy to transport mud.

The main components of the mud pump power end are:

Base, frame, pinion shaft assembly, large gear shaft assembly, crosshead assembly, transmission unit or DC motor, etc.;

The main components of the mud pump liquid end are:

Liquid cylinder, suction valve, discharge valve, cylinder liner, piston, piston rod (plunger, packing and cylinder liner) suction pipe, suction air bag, discharge pipe, discharge filter assembly, discharge air bag, safety valve, cylinder Cover, valve cover, spray pump assembly.

Working principle of mud pumps

The mud pump is a reciprocating plunger pump that converts rotational motion into reciprocating linear motion of the crosshead and piston through a crank connecting rod mechanism, compressing low-pressure mud into high-pressure mud. During the drilling process, drilling fluid with high viscosity, large specific gravity and high sand content is transported to the bottom at high pressure to cool the drill bit, flush the bottom of the well, break rocks, and carry cuttings when returning from the bottom of the well. It is an important part of oil drilling. And operate one of the most important process equipment.

The working process of the mud pump is divided into two steps: suction process and discharge process.

Traditionally, we divide mud pumps into two parts: the liquid end and the power end. The power end is used to transmit power and convert movement modes and speeds. Provide appropriate power for the liquid end; the liquid end is used to convert mechanical energy into liquid internal energy to transport mud.

Inspection before starting the mud pumps

1. Ensure that all relatively moving parts are effectively lubricated and the temperature is normal.

2. Make sure the cooling device is working properly.

3. The connection sealing device is reliable.

4. Check all valves on the mud pipeline to see if they are in the correct state before starting.

5. Check whether the inflation pressure of the air bag meets the requirements.

6. Check whether the pump pressure gauge and safety valve are in normal position.

Inspection precautions after starting the mud pumps

1. Check the water supply situation

2. Check whether the connection card between the piston tie rod and the middle tie rod makes any abnormal noise, and check whether all bolts, nuts, valve covers, and cylinder heads on the hydraulic cylinder are loose. If any abnormal noise is found, it should be dealt with in time.

3. Check whether there is leakage in the alarm holes at each high-pressure seal (F pump), and whether there is a piercing leakage sound in the pump valve and cylinder head. If any problems are found, deal with them in time.

4. Pay attention to changes in pump pressure and handle abnormalities appropriately if found.

5. Pay attention to whether the sound of each operating part is normal, and pay attention to the water supply of the spray pump.

6. Pay attention to whether the temperature of each bearing part, crosshead guide plate and other parts with relative motion is too high or there are any abnormalities.

7. The basic elements for the normal operation of a drilling pump are: medium power, medium pump pressure, medium speed operation, no loosening of the tightening, no leakage of the seal, no fluctuation of pump pressure, normal temperature, and normal sound.

8. Overload operation is strictly prohibited. Use large pistons and low pump speeds as much as possible.

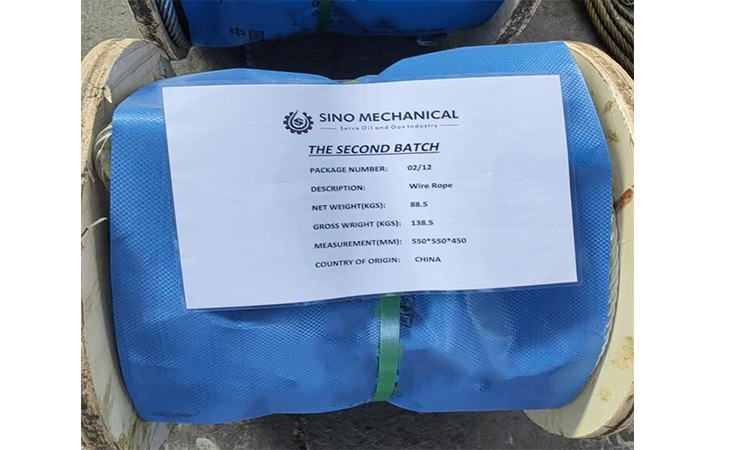

Sino Mechanical Equipment provides various oil drilling equipment, such as: drilling mud pumps and accessories, diesel engines, air winches, drawworks, traveling block and hook combinations, wire ropes, etc. It is committed to developing and providing high-quality oil drilling equipment to meet the changing needs of customers and contribute more to the development of the petroleum industry.