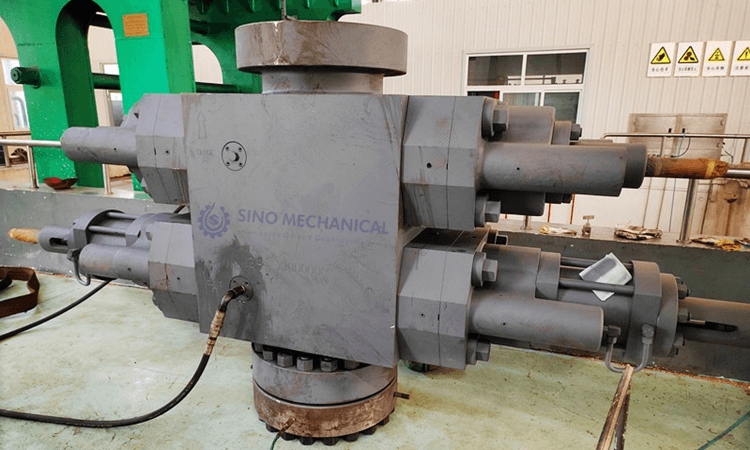

Drill Pipe Delivered to South Africa Successfully

RFQ of drill pipe with technical specifications as per below was received two month ago from our client in South Africa.

1. 3 1/2" Drill pipe, G105, NC38, NW 13,3, QTY: 350 PCS

2. 4-1/2" Drill pipe, G105, NC50, N W 16,6, QTY: 350 PCS

As our client needs those drilling pipes urgently for their oil well drilling operation. Sino Mechanical delivered 700 PCS drilling pipes to China port with in 15 days. Relying on our strong supplier system and professional technical team, Sino Mechanical found all the drill pipes in stock quickly.

Sino Mechanical is located in the second largest oil field in China, Shengli Oilfield. And our group company is mainly responsible for domestic drilling business. We are mainly responsible for foreign drilling business. So we can quickly find the stock of the oilfield equipment that customers need urgently. What's more we can guarantee high quality and best price because we have more than 20 years experience in the field of oil and gas. Sino Mechanical delivers drilling equipment, rig equipment and oil refinery equipment to global.

Our goal is to be your one stop oilfield equipment supplier port.

What is a drill pipe?

Drill pipe is the main tool in oil and gas drilling and geological survey. The drill pipe is made of seamless steel pipe. It is used to connect surface drilling rigs and equipment such as drill bits at the bottom of the well.

Oil drill pipes are not only affected by the complex downhole environment during service, but also subjected to various alternating stresses, such as tension, compression, torsion, bending, impact, etc.

With the continuous complexity of the underground environment of coal mines, the performance requirements of customers for drill pipes are gradually increasing. Due to the continuous application of mine drilling technology, drilling costs and drilling risks are also increasing. Traditional drill pipes can no longer meet the requirements of use. The new generation of drill pipe newly developed and produced by Sino Mechanical is developing towards high strength, high toughness, corrosion resistance, safety and environmental protection. And we are committed to continuously intelligentizing drill pipes. In addition, we have further improved the transmission data rate and temperature resistance of the drill pipe.

Types of drill pipe

Drill pipe can be divided into three categories. And they are kelly, platform drill pipe and heavy weigh drill pipe.

(1) Kelly: The kelly is located at the top of the drill string, and there are two types: square and hexagonal. The function of the kelly is to cooperate with the core bushing and the rotary table core bushing during drilling. It then transfers the ground rotation torque to the drill pipe. In this way, it can drive the drill string and drill bit to rotate. Moreover, the kelly can bear the full weight of the drill string. The kelly is also a channel for drilling fluid circulation.

(2) Ordinary drill pipe: it is the basic component of the drill string. Its main function is to transmit torque and transport drilling fluid. Moreover, it relies on the gradual lengthening of the drill pipe to continuously deepen the wellbore. Therefore, drill pipe plays a very important role in oil drilling.

(3) Heavy weight drill pipe: Heavy drill pipe is similar to oil drill pipe, and it is also a hollow steel column. The length of the heavy drill pipe is about 10 meters. However, the single weight of the weighted drill pipe is heavier than that of the oil drill pipe. The wall thickness of the weighted drill pipe is 2-3 times that of the drill pipe. The weighted drill pipe is connected between the drill pipe and the drill collar. It prevents fatigue failure due to changes in the section of the drill string. It can also replace part of the drill collar. The suspension of the heavy drill pipe is simple, and the tripping operation is convenient. Using heavier drillpipes also saves tripping time.

Function of drill pipe

The drill pipe plays the role of transmitting power and transporting drilling fluid and mud. Moreover, the drill pipe also plays a role in lifting, lowering or rotating the drilling and grinding equipment at the bottom. At the same time, the high-pressure flushing fluid also flows to the bottom of the well through the inner hole of the drill pipe.

Production process of drill pipe

The production process of drill pipe can be roughly divided into blanking, rough turning, modulation heat treatment, thread machining, nitriding treatment, friction welding, spraying, and packaging. In the whole processing process, modulation heat treatment and friction welding process are important processes that affect the performance of drill pipe.

Price of Drill Pipe

The drill pipe Price will change randomly with factors such as production cost, transportation cost, international situation, exchange rate, market supply and demand of raw materials. Sino Mechanical aims to provide you with high quality and best price drill pipe. If you are looking for drill pipe, please kindly contact us to get the latest drill pipe price.

Drill Pipe Supplier

Sino Mechanical, as a drill pipe manufacturer, has more than 20 years extensive experiences in the performance, application and cost-effective manufacturing of drill pipe. We are global drill pipe supplier. We offer a wide range of drilling equipment and have different types of drill pipe for sale. We also provide OEM services. We design, manufacture, and sell drill pipe for your drilling applications. If you want to know latest drill pipe price or get drill pipe specifications, send your RFQ to sales@sinomechanical.com. Or call us at +8613949215821. We will get back to you within 24 hours.