Double Ram BOP Shear Testing and Pressure testing

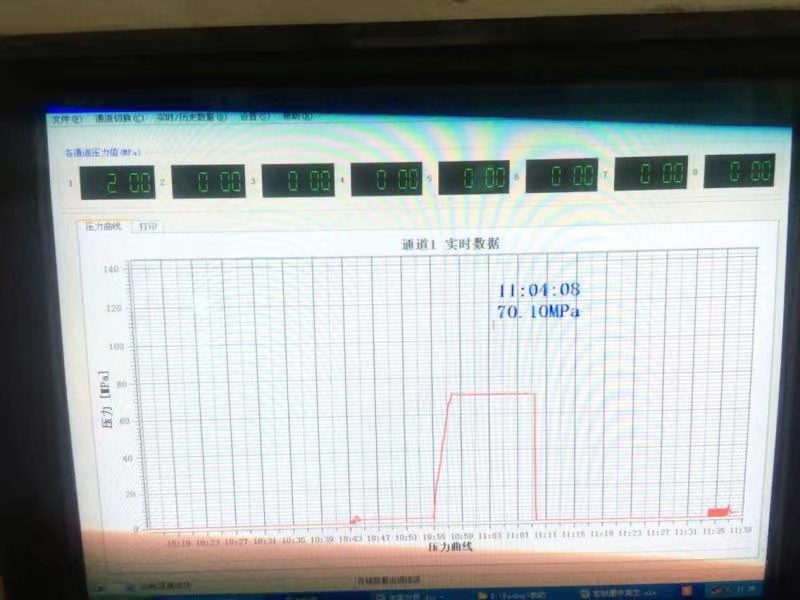

PO of double ram BOP was received from customers from Kuwait. The delivery time is 25 working days for customers’ urgent operation requirements. We make good preparations for the production and finish each step very well and save time as well. Finally, the production of this double ram BOP was finished within 20 days. And we conduct shear testing and pressure testing under the witness of DNV third party inspection team. The testing result is successfully and we will paint this double ram BOP ASAP to catch up the delivery time. The doublt ram BOP is with following technical specifications,

Blowout Preventer

Double Ram, 13 5/8”

Working Pressure: 10,000 PSI

Type U Chinese,

Studded Top: 13 5/8″, 10,000PSI, BX159

Studded Bottom: 13 5/8″, 10,000PSI, BX159

Studded Side Outlet: 4 1/16″ , 10,000PSI

With inner seals and Tandem Booster

A blowout preventer (BOP) is a large, specialized valve that is mounted on top of the well during the drilling and completion stages of operation used to seal, control and monitor oil and gas wells.

During drilling, mud is pumped down the drill string to lubricate and cool the bit, and provide equalizing pressure in the well. If the well’s hydro-static pressure falls below the formation’s pressure, a kick can occur, allowing gas, oil, and saltwater fluids to enter the well bore. The BOP has the capability to control this flow by sealing off the well bore in several ways.

We understand the importance of Blowout Preventer during drilling operations for drilling contractor, and we will ensure the safety, quality and fast delivery time at the same time. Any requirements for wellheads made in China, contact us anytime.

What is Double Ram BOP?

The ram BOP uses hydraulic pressure to push the sealing element from the left and right sides to the center of the wellbore to close the wellhead. Because the sealing element is two set of rams with rubber cores, it is called a ram blowout preventer.

The hydraulic double ram BOP is designed to effectively control blowout during oil (gas) testing. The hydraulic double ram BOP is also used for workover and measurement data of low-pressure wellheads. The hydraulic double ram BOP can be used alone or in combination with a single ram BOP. It can also be used in conjunction with annular BOP.

Features of Double Ram BOP

Sino Mechanical double ram BOP is designed and manufactured according to API16A standard. BOP is available with variable rams in different sizes. It has pipe ram, blind ram, shear ram and blind shear ram. In order to save the time of replacing the ram, the design of the variable ram is also adopted.

The rubber core at the front of the gate is of good quality. The top rubber core and the middle flange sealing group can meet extreme working conditions, such as high and low temperature and acidic environment.

The shell material is low alloy steel casting or forging. The chemical composition, mechanical properties and forming process all meet the corresponding standard requirements.

1. The hydraulic sealing time of the fast-acting annular blowout preventer is generally not more than 30 seconds.

The hydraulic sealing time of the ram BOP is 3-8 seconds.

The time to open the hydraulic discharge valve is 3 seconds.

2. Easy to operate. Safe and reliable. The opening and closing of the blowout preventer at the wellhead are hydraulically operated. Pneumatic or hydraulic control.

3. On-site maintenance is convenient. If the ram of the ram BOP is broken or the packing element of the annular BOP is broken, they can be replaced on site.

What is the difference between a pipe RAM and an annular BOP?

The annular BOP helps seal the space around the drill pipe (also known as annular space). However, a ram BOP is designed to seal off a well when the drill pipe, tubing, or casing is in the well.

The connection ways of Double Ram BOP

There are three connection methods for the top and bottom. And they are studded, flanged and clamped.

The dimensions of connecting flanges, bolts, clamps, and steel ring grooves are all in accordance with API6A and API16A standards.

Ram BOP Technical Specifications

1. Nominal diameter

Definition: The diameter of the upper and lower through holes inside the blowout preventer, in mm.

Types: 180mm, 230mm, 280mm, 346mm, 426mm, 476mm, 528mm, 540mm, 680mm.

2. Definition of rated working pressure

The maximum wellhead pressure that the blowout preventer can withstand when it is working, in MPa.

Type: 14MPa, 21MPa, 35MPa, 70MPa, 105MPa.

Applications of Double Ram BOP

1. When there is a pipe in the well, it can close the annular space between the casing and the tubing.

2. When there is no drilling tool in the well, use the blind shear ram to seal the empty well.3. In order to effectively control the formation pressure, Double Ram BOP can be used in conjunction with the oil (gas) test manifold to achieve balanced pressure operations.

3. Special operations such as well killing and well washing can be realized under the condition of closing the wellhead.

During normal drilling operations, the drilling mud pump sucks the drilling fluid from the drilling fluid tank and circulates it to the bottom of the well through the surface high-pressure manifold, standpipe, hose, swivel, kelly, drill pipe, drill collar, and drill bit. And then it carries the cuttings back up the annular space to the wellhead, and then the drilling fluid is exported to the shale shaker, degasser, and desander through the overflow prevention pipe. The purified drilling fluid returns to the drilling fluid tank. After the overflow occurs, close the blowout preventer and shut down the well. When the well killing operation is performed, the drilling fluid pump will suck the drilling fluid from the drilling fluid tank. Through the surface high-pressure manifold, standpipe, hose, faucet, kelly, drill pipe , drill collars, and drill bits to the bottom of the well. Replace the intrusive fluid in the well, and pass through the four-way side hole to the choke manifold. Regulate the annular pressure through the choke valve. The returned drilling fluid is led to the drilling fluid gas separator through the return pipeline. After the intrusive gas is removed, the qualified drilling fluid is led to the drilling fluid tank. The removed gas is led to a safe place for combustion through the exhaust pipeline to prevent pollution.

Price of Double Double Ram BOP

The Double Ram BOP Price will change randomly with factors such as production cost, transportation cost, international situation, exchange rate, market supply and demand of raw materials. Sino Mechanical aims to provide you with high quality and best price double Ram BOP. If you are looking for double Ram BOP or Ram BOP spares, please kindly contact us to get the latest Ram BOP price.

Supplier of Double Ram BOP

Sino Mechanical, as a Ram BOP manufacturer, has more than 20 years extensive experiences in the performance, application and cost-effective manufacturing of Ram BOP. We are global Ram BOP supplier. We offer a wide range of drilling equipment and have Ram BOP for sale. We also provide OEM services. We design, manufacture, and sell Ram BOP for your drilling applications. If you want to know latest Ram BOP price, don't hesitate to call us at +8613949215821 or send your RFQ to sales@sinomechanical.com.We will get back to you within 24 hours.