Description

Overview of Hose Loops

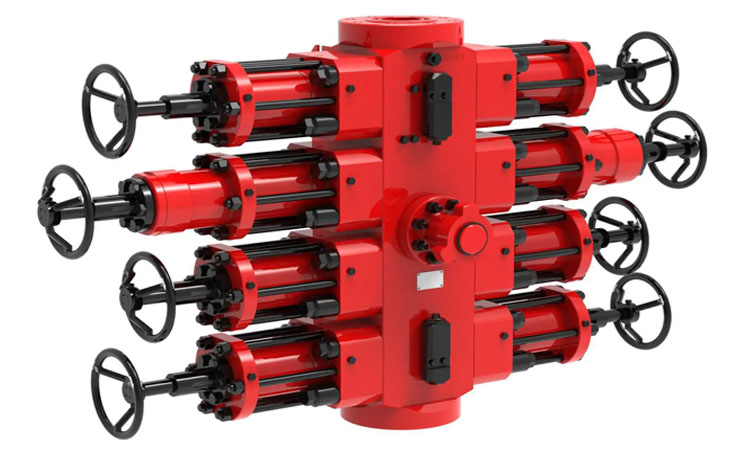

The hose loop is assembled by swivel joints, hammer union and pup joint, it can be swiveled in three directions flexibly.

Hose loops are used in a wide variety of well service applications, such as circulating lines, water lines, discharge lines, well test lines and temporary flow lines. Sino Mechanical hose loops are used most extensively for primary and secondary cementing operations.

Sino Mechanical Hose Loops include long radius type and flexible type. Long radius type combines long radius swivel joint and integral pup joint. Our hose loops can easily move in any lateral direction. The swivel joint used in our hose loops is also used to control vibration and absorb shock. Our new advanced material results in better heat treatment and more durable products. With this new material, we have been able to extend the life of our hose loops even further.

Features of Hose Loops

1. Special repair kit is available for quick and inline maintenance.

2. Easy to fold, store and transport.

3. High flexibility, less vibration, impact resistance and large flow

4. Integral hammer union connection is easy for assembly and disassembly. The hose loop is connected by union, which is simple to assemble and disassemble, crush resistance, and with high sealing performance.

5. The hose loop is characterized by flexibility, impact resistance, vibration resistance, big rate of flow, etc.

6. It has the advantage of easy fold ability, convenient transportation and storage.

7. The thread joint conforms to international specifications.

Applications of Hose Loops

1. Hose loops are used in a wide variety of well service applications, such as circulating lines, water lines, discharge lines, well test lines and temporary flow lines.

2. Hose Loop is usually used in discharge pup joint, transportation pup joint, well testing pup joint, well-cementing pup joint, and transportation liquid flow under a high-pressure environment.

Price of Hose Loops

The Hose Loops Price will change randomly with factors such as production cost, transportation cost, international situation, exchange rate, market supply and demand of raw materials. Sino Mechanical aims to provide you with high quality and best price Hose Loops. If you are looking for Hose Loops, please kindly contact us to get the latest Hose Loops price.

Hose Loops Supplier

Sino Mechanical, as a Hose Loops manufacturer, has more than 20 years extensive experiences in the performance, application and cost-effective manufacturing of Hose Loops. We are global Hose Loops supplier. We offer a wide range of drilling equipment and have Hose Loops for sale. We also provide OEM services. We design, manufacture, and sell Hose Loops for your drilling applications. If you want to know latest Hose Loops price, don’t hesitate to contact us anytime. We will get back to you within 24 hours.

Specification

Technical Specifications of Hose Loops

Product Name: Circulating Hose Loop, Chiksan Hose Loop

Material Class: AA-EE

Type: Long radius, short radius

Customized: Please provide size, type, pressure, length etc. or drawing

RATED WORKING PRESSURE | 69.0MPa~138.0Mpa | |

NOMINAL SIZE | 1″, 1″×2″, 1 1/2″, 2″, 2″×3″, 3″, 4″ | |

TEMPERATURE RATING | -29℃~121℃(PU), -46℃~121℃ (LU) | -20℉~250℉ (PU), -50℉~250℉(LU) |

SERVICE | Standard, Sour Gas | |

APPLICATION | Fracturing, Cementing, Acidizing, Testing Lines | |