Description

Overview of Choke and Kill Lines

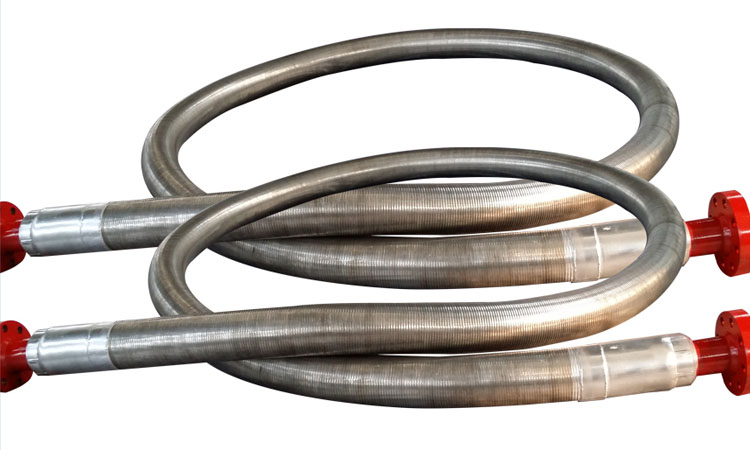

Choke and kill hoses are essential to control the well control equipment. Sino Mechanical Choke and Kill Lines are specifically designed to handle the high pressures and flow rates this use requires.

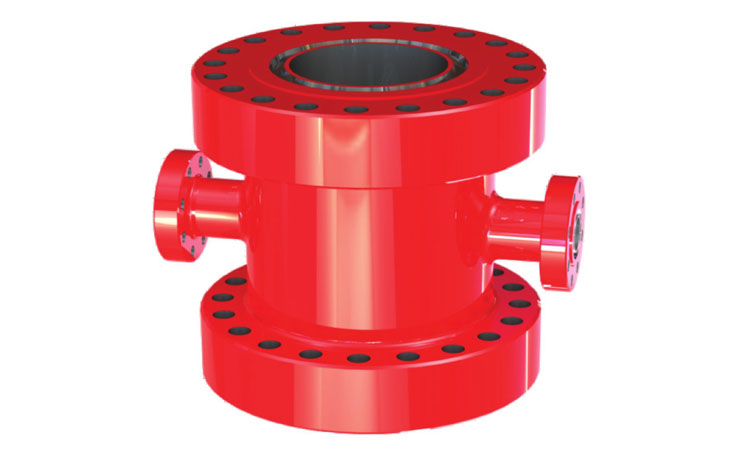

Choke and Kill Lines allows fluids to be pumped into or removed from the well with the BOPs closed. External conduit arranged laterally along the riser pipe and used for circulation of fluids into and out of the wellbore to control well pressure.

Kill line is the pumping outlet connected to Mud cross/drilling spool below BOP stack, allow to pump fluid thru it to the annulus while killing/filling operations. A kill line can help watch the wellbore's pressure. Kill Line is a high-pressure line that connects the mud pump and the well and through which heavy drilling fluid can be pumped into the well to control a threatened blowout.

Choke line is a line connected to mud cross/ drilling spool below BOP stack, lined up to choke manifold. Its allow to divert the return from the well to the mud system/poor boy/flare pit while killing operation and establish choking pressure on the well if required.

Choke Line is an extension of pipe from the blowout preventer assembly used to direct well fluids from the annulus to the choke manifold.

Features of Choke and Kill Lines

1. The reinforcement layer of the Choke and Kill Lines is made of imported high-strength steel wire of the spiral rubber hose. The rubber of the inner lining layer is made of the original rubber of German Lanxess Company. Synthetic materials are used as the sealing layer, and different formulas are adopted according to different media.

2. According to the pressure and use environment, the flange joints at the end of the Choke and Kill Lines use 45K/60K/75K. The material is anti-corrosion treated and heat treated. The flange adopts a swivel flange. Integral forging process is used, and there is no need to consider the alignment problem during installation

3. The fire resistance of the Choke and Kill Lines meets the standard of rated working pressure under the flame temperature of 704℃ for 30mins. The exterior adopts stainless steel telescopic joint armor structure.

4. Can withstand oil-based mud, water-based mud.

5. The inner wall of Choke and Kill Lines is highly wear-resistant and can withstand the flow rate of high-speed mixed mud.

6. Can withstand extreme weather such as high temperature and severe cold.

7. Choke and Kill Lines is both corrosion resistant and anti static.

Applications of Choke and Kill Lines

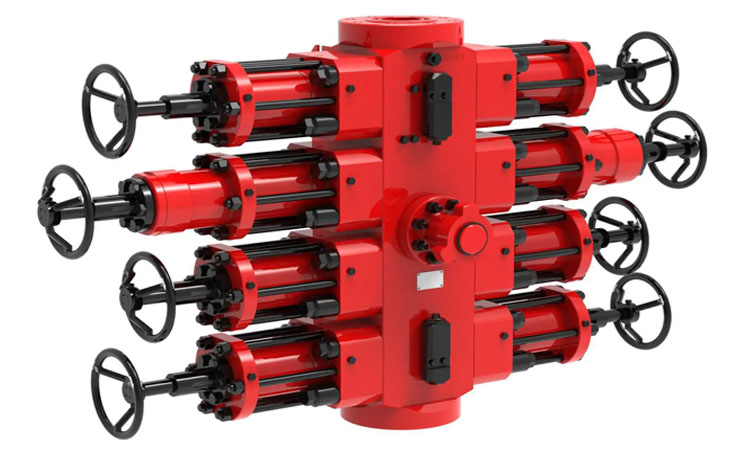

The choke and kill lines provide durable, high-pressure systems for directing fluid flow in normal drilling operations as well as hazardous well control operations.

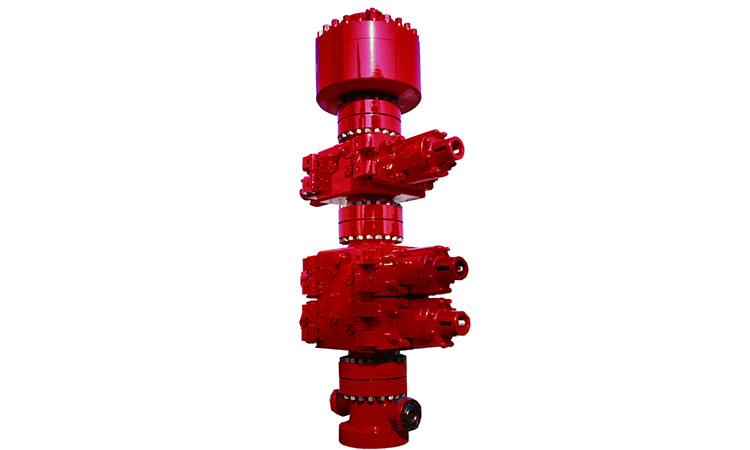

1. It is suitable for the connection between choke manifold, kill manifold and drilling spool in oil drilling.

2. The relative movement of the drilling platform, semi-submersible drilling ship or drilling ship, and the change of the installation size of the drilling rig, etc.

3. Transport oil, gas, mud and other high-pressure media.

4. Choke and Kill Lines can also be used for the connection between the mud tank and the liquid-gas separator.

Price of Choke and Kill Lines

The Choke and Kill Lines Price will change randomly with factors such as production cost, transportation cost, international situation, exchange rate, market supply and demand of raw materials. Sino Mechanical aims to provide you with high quality and best price Choke and Kill Lines. If you are looking for Choke and Kill Lines, please kindly contact us to get the latest Choke and Kill Lines price.

Choke and Kill Lines Supplier

Sino Mechanical, as a Choke and Kill Lines manufacturer, has more than 20 years extensive experiences in the performance, application and cost-effective manufacturing of Choke and Kill Lines. We are global Choke and Kill Lines supplier. We offer a wide range of drilling equipment and have Choke and Kill Lines for sale. We also provide OEM services. We design, manufacture, and sell Choke and Kill Lines for your drilling applications. If you want to know latest Choke and Kill Lines price, don’t hesitate to contact us anytime. We will get back to you within 24 hours.

Specification

Technical Specifications of Choke and Kill Lines

Inter dia. | Rated operating | Test pressure in | Min. burst pressure in | Min. bending radius |

50.8(2) | 35.0(5 000) | 52.5(7500) | 78.75(11250) | 900 |

64(2 1/2) | 1000 | |||

76.2(3) | 1000 | |||

89(3 1/2) | 1100 | |||

101.6(4) | 1200 | |||

50.8(2) | 70.0(10 000) | 105.0(15 000) | 157.5(22 500) | 1000 |

63.5(2 1/2) | 1100 | |||

76.2(3) | 1150 | |||

89(31/2) | 1200 | |||

101.6(4) | 1250 | |||

50.8(2) | 105.0(15000) | 157.5(22500) | 236.25(33750) | 1000 |

63.5(2 1/2) | 1150 | |||

76.2(3) | 1200 | |||

50.8(2) | 138.0(20000) | 207.0(30000) | 310.0(45000) | 900 |

64(2 1/2) | 1100 | |||

76.2(3) | 1200 |