Description

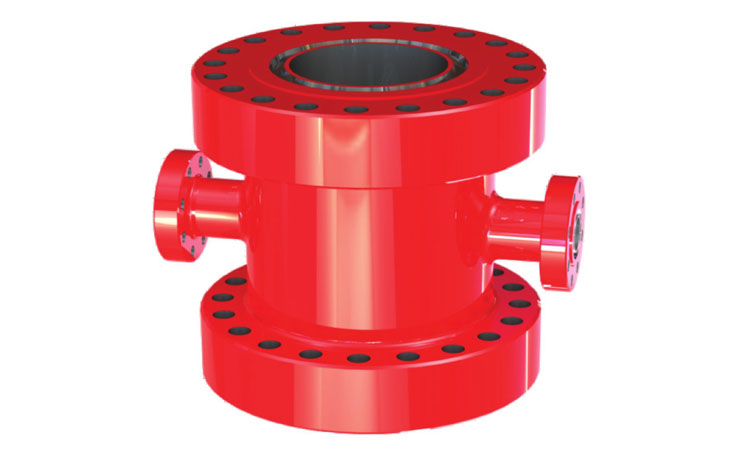

Overview of Annular BOP

Annular BOP is a large valve resembling a large rubber donut and mechanically squeezes inward to seal the drill collar, drill pipe, casing, tubing, open hole, wireline or pipe.

Annular BOP consists of body, upper housing, packing element, dust-proof ring, and piston. Annular BOP plays an essential role in keeping oilfield safe.

The annular blowout preventer is controlled by the hydraulic system. When the well is closed, the hydraulic oil enters the closed cavity of the lower part of the piston from the lower oil port of the casing, and pushes the piston to move upward, forcing the rubber core to move upward to the center, so that the reinforcing ribs are close to each other, and the rubber in between is squeezed to the center of the wellhead. Realize closed drilling tool or fully sealed wellhead.

Annular blowout preventer is an important part of well control equipment, which is mainly used to control wellhead pressure in drilling, workover service and oil testing operations, effectively prevent blowout accidents and realize construction. Annular blowout preventer is named for its packing element - rubber core ring. Also known as universal BOP, multi-effect BOP or spherical BOP.

According to the shape of the packing element of the annular BOP, it can be divided into annular BOP with conical rubber core, annular BOP with spherical rubber core, and annular BOP with combined rubber core. When there are drilling tools, tubing or casing in the well, the annular blowout preventer can seal various annular spaces with rubber cores, and can seal the wellhead for drilling when there is no drilling tool in the well.

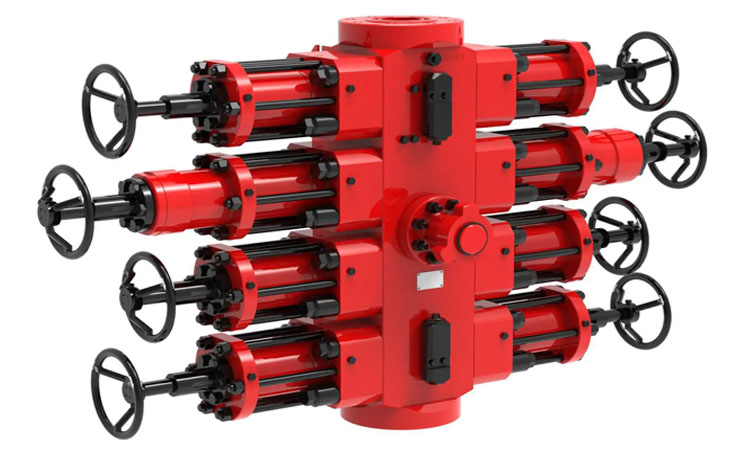

The blowout preventer is used to close the wellhead in the process of oil testing, workover, and completion to prevent blowout accidents. It combines the functions of full seal and half seal. It has the characteristics of simple structure, easy operation, and high pressure resistance. , is a safety sealing wellhead device commonly used in oil fields to prevent blowout.

During oil drilling, it is installed on the wellhead casing head to control the blowout device for high-pressure oil, gas and water. When the oil and gas pressure in the well is very high, the blowout preventer can close (shut off) the wellhead. When heavy mud is pressed from the drill pipe, there is a four-way under the ram, which can replace the gas-invaded mud and increase the pressure of the fluid column in the well to suppress the high-pressure oil and gas ejection.

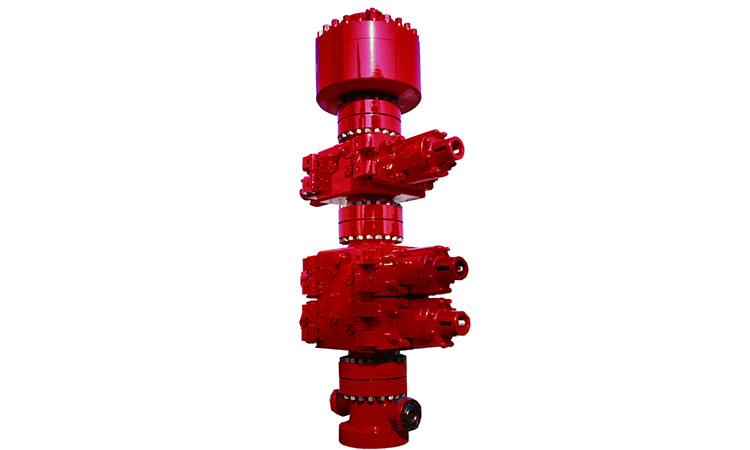

The types of BOP are ordinary BOP, universal BOP and rotary BOP. The universal blowout preventer can be activated in an emergency to deal with drilling tools and empty wells of any size; the rotary blowout preventer can realize drilling while spraying. In deep well drilling, in addition to two common blowout preventers, universal blowout preventer and rotary blowout preventer are often added, so that three or annular blowout preventers, Annular Blow-out Preventer, are usually equipped with large-scale ram type blowout preventers. When the gate is in operation, a sealed annular space will be formed between the pipe string and the wellbore. When there is a pipe string in the well, it can also complete the well closure alone, but it will not work after several times of use, and it is not allowed to shut down the well for a long time . Four kinds of blowout preventers are assembled on the wellhead.

Blowout preventer is the most important well control device, which plays an important role in drilling, especially underbalanced drilling. BOPs are designed to close the wellbore under pressure, maintain continuous control of the well, and circulate formation fluids entering the well.

When there are drilling tools, tubing or casing in the well, the annular blowout preventer can use a rubber core to seal various annular spaces of different sizes. When there is no drilling tool in the well, it can fully seal the wellhead for drilling, coring and testing. During well operations, it can also close the annular space formed by the kelly, coring tools, cables, steel wires, etc.

The annular BOP must be equipped with a hydraulic control system before it can be used alone. It is usually used in conjunction with the ram BOP, or it can be used alone. The annular blowout preventer can complete the following tasks: seal tools such as kelly, drill pipe joints, drill collars, casings and cables of various shapes and sizes; when there is no drilling tool in the well, it can completely seal the wellhead; Under the condition of the hydraulic control device of the pressure regulating valve or the control of the buffer accumulator, the drilling tool can be forced to trip through the drill pipe joint of the 18°C shoulder.

Annular BOP provides a rugged, reliable preventer and ease of service and widely used Offshore (subsea and surface) and onshore. Annular BOP is compact, seal any size kellys, drill pipe, tool joints, drill collars, casing or wireline. Sphericals also provide positive pressure control for stripping drill pipe into and out of the hole.

The Annular BOP consist of

Top Cover

Packing Element of Annular BOP

Dust Ring

Piston

Shell of Annular BOP

Features of Annular BOP

1. Compact structure, saving space

2. The radial section of the piston is "Z" shaped, with a short stroke, low height, and no machining wear-resistant belt

3. The top cover adopts spherical structure, there is no stress concentration phenomenon under pressure, the shell is evenly stressed, and it is easy to disassemble and assemble

4. The spherical rubber core has a large amount of rubber storage, reliable sealing and long service life

5. The moving parts are equipped with wear-resistant rings to reduce the wear of the seal ring and prolong the service life of the seal

6. Multiple supporting ribs distributed around the circumference are embedded in the rubber core, which is not easy to tear when sealing

7. High pressure, easy operation, quick switch.

8. Seal pipe strings of various shapes and sizes, and can also fully seal the wellhead.

9. The sealing ring adopts a lip-shaped sealing ring, which has a long service life

10. Surfacing high-nickel-based alloys on all parts of the high-sulfur blowout preventer that are in contact with well fluid can achieve the effect of H2S resistance.

Precautions of the Use of Annular Blowout Preventers

1. If a blowout occurs when there is a drilling tool in the well, the wellhead can be controlled with an annular blowout preventer first, but try not to seal it for a long time. One is that the rubber core is easily damaged, and the other is that there is no locking device. It is not used to seal the empty well under special circumstances.

2. For snubbing operation with annular blowout preventer, drilling tools with 18-degree slope must be used. When going through joints, the tripping speed should be slow, and all rubber hoops on all drilling tools should be removed.

3. When the annular blowout preventer is closed, the shut-in pressure is below 5MPa, and the drilling tool can be moved up and down, but it is forbidden to rotate the drilling tool.

4. It is strictly forbidden to release the pressure in the well by opening the annular blowout preventer to prevent the rubber core from being damaged.

5. After each well opening, it must be checked whether it is fully opened to prevent the rubber core from being damaged.

6. After cementing, plugging and other operations, the inner cavity should be rinsed clean and the switch should be kept flexible.

7. When installing or dismantling the annular blowout preventer, special attention must be paid to the gasket ring and steel ring groove, and no damage or scratch is allowed.

8. After entering the target layer, each time the drill is tripped out, the well should be shut in once with drilling tools to check the sealing effect of the rubber core. If it does not meet the requirements, it should be replaced immediately.

9. According to the relevant standards, the pressure test of the annular blowout preventer at the wellhead should be carried out regularly.

10. Only the 18-degree butt welded drill pipe joint without fine button is allowed.

11. During the tripping process, there is a small amount of leakage between the rubber core and the drill pipe, which is not only allowed, but also necessary. A small amount of leaked drilling fluid can lubricate and cool the rubber core and improve the life of the rubber core. If necessary, add lubricating fluid to the top of the rubber core to lubricate the rubber core.

12. The tripping speed must be slow, especially when passing through joints.

Applications of Annular BOP

1. When there is a pipe string in the well, a rubber core can be used to close the annular space formed by the pipe string and the wellhead.

2. When the well is empty, the wellhead can be fully sealed.

3. In the process of drilling and milling, casing grinding, well logging and salvage of well falling objects, if overflow or blowout occurs, it can seal the space formed by kelly, cables, wire ropes, tools for handling accidents and the wellhead.

4. With the cooperation of pressure reducing and regulating valves or small accumulators, it is possible to forcibly lift and lower 18° butt welded pipe joints without fine buttons.

5. In case of severe overflow or blowout, it is used to cooperate with ram blowout preventer and choke manifold to realize soft shut-in.

Price of Annular BOP

The Annular BOP Price will change randomly with factors such as production cost, transportation cost, international situation, exchange rate, market supply and demand of raw materials. Sino Mechanical aims to provide you with high quality and best price Annular BOP If you are looking for Annular BOP, Annular BOP parts, or Annular BOP packing element, please kindly contact us to get the latest Annular BOP price.

Annular BOP Supplier

Sino Mechanical, as a Annular BOP manufacturer, has more than 20 years extensive experiences in the performance, application and cost-effective manufacturing of Annular BOP We are global Annular BOP supplier. We offer a wide range of drilling equipment and have Annular BOP for sale. We also provide OEM services. We design, manufacture, and sell Annular BOP for your drilling applications. If you want to know latest Annular BOP price, don’t hesitate to contact us anytime. We will get back to you within 24 hours.

Specification

Technical Specifications of Annular BOP

MODEL | MAIN BORE | WORKING PRESSURE | OPERATING PRESSURE MPA | CONNECTION TYPE | DIMENSION MM MM | WEIGHT KG | ||

TOP | BOTTOM | OD | HEIGHT | |||||

FH18-21 | 179 (7-1/16) | 21(3000) | 8.4~10.5 | studded | fanged | 737 | 743 | 1350 |

FH18-35 | 35(5000) | 737 | 790 | 1572 | ||||

FH18-70/105 | 70(10000) | 1092 | 1136 | 5070 | ||||

FH23-21 | 228 (9) | 21(3000) | 900 | 830 | 2104 | |||

FH23-35 | 35(5000) | 998 | 1200 | 3540 | ||||

FH28-21 | 279 (11) | 21(3000) | 1013 | 838 | 2574 | |||

FH28-35 | 35(5000) | 1138 | 1081 | 4410 | ||||

FH28-35/70 | 35(5000) | 1138 | 1096 | 4451 | ||||

FH28-70/105 | 70(10000) | 1448 | 1420 | 10800 | ||||

FH35-35 | 346 (13-5/8) | 35(5000) | 1270 | 1160 | 6400 | |||

FH35-35/70 | 35(5000) | 1270 | 1227 | 6843 | ||||

FH35-70/105 | 70(10000) | 1640 | 1664 | 15110 | ||||

FH43-35 | 425 (16-3/4) | 35(5000) | 1524 | 1320 | 10834 | |||

FH48-70 | 476 (18-3/4) | 70(10000) | 1937 | 1882 | 27161 | |||