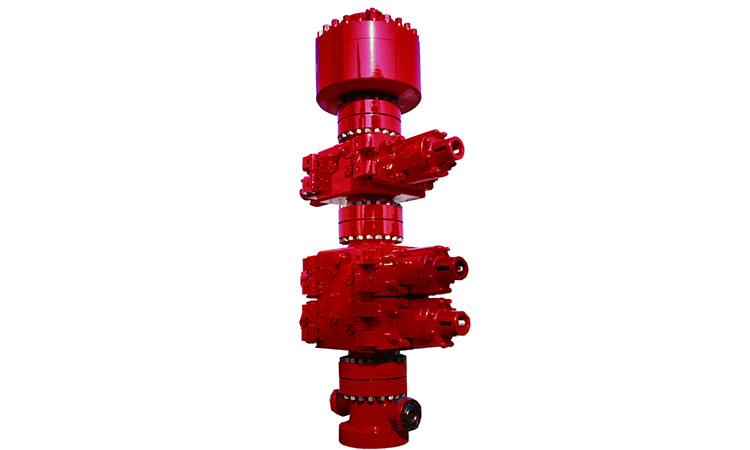

The blowout preventer unit is a new generation of well control equipment developed by our company, which can meet the well control process requirements of high pressure oil and gas drilling.

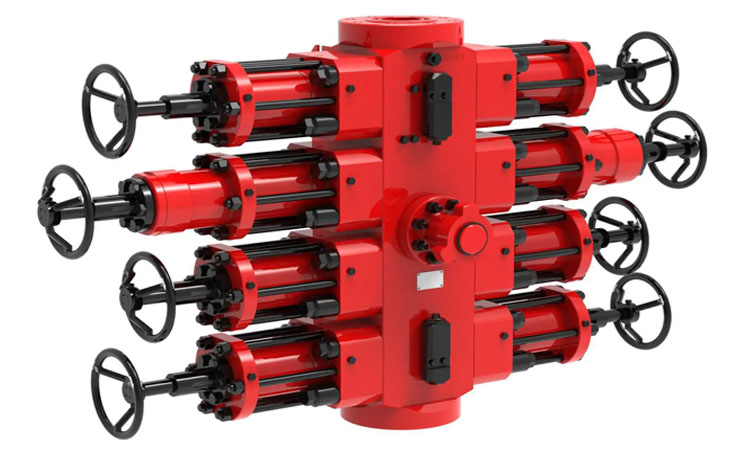

Sino Mechanical offers reliable, cost-effective, high-performance, robust, and and reliable Single Ram BOP and Double Ram BOP. Our Ram BOPs are available in different sizes and pressure rating to meet the requirements of the client.

Annular blowout preventers are mainly used in drilling, workover operations and oil testing operations, which can effectively prevent blowouts. Sino Mechanical annular blowout preventers use lip seals and have a long service life.

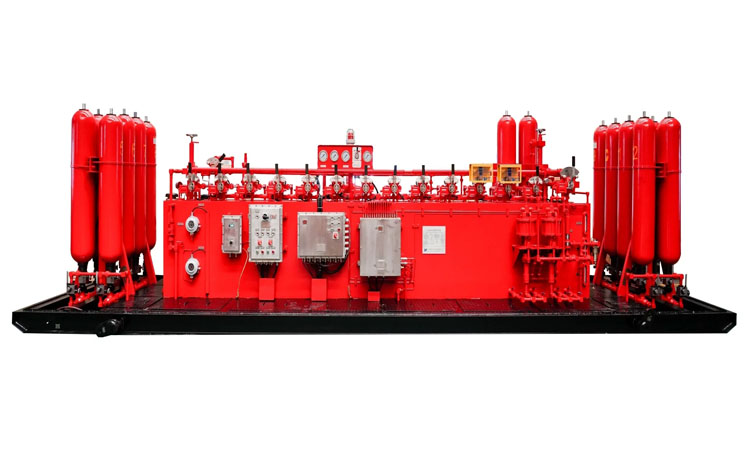

Offer high-performance and reliable Accumulator Unit, BOP Control System, Koomey Unit, BOP Closing Unit for drilling and workover operations.

Sino Mechanial designs, manufactures and sells coiled tubing blowout preventers for your drilling applications, which are designed to provide wellbore isolation, blowout protection and safety in emergency situations.

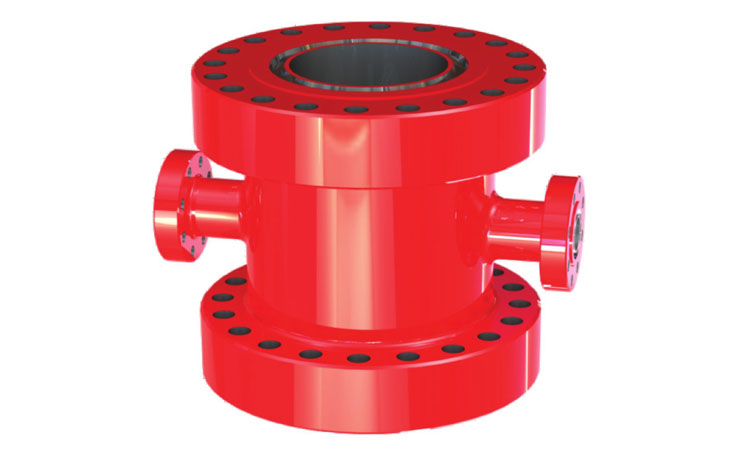

Drilling Spools are the parts which are often used in the oilfield when drilling. Sino Mechanical offers studded crosses & tees for various sizes and pressure ratings in accordance with API product specification.

Sino Mechanical offers reliable hard surface, tough core and long service life Swivel Joints for fracturing, cementing, acidizing and testing lines.

Flowline plug valve is an important high pressure part for well service. Sino Mechanical plug valve has advantages of compact structure, easy maintenance, low torque and rapid operation.

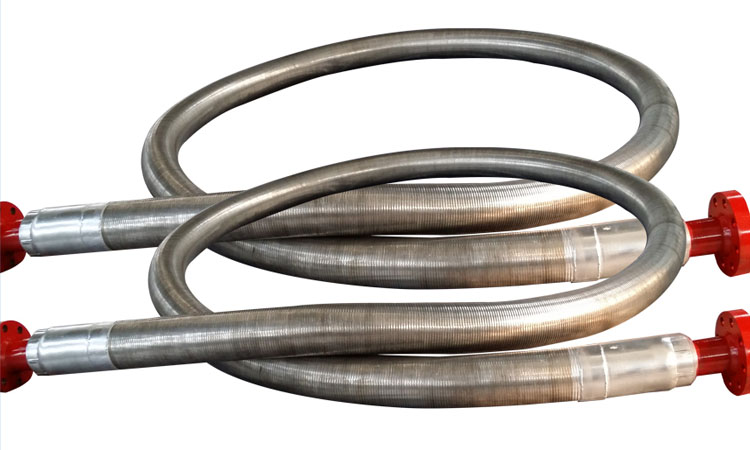

Sino Mechanical Hose Loops features high erosion resistance, less vibration, impact resistance and large flow. Hose Loops are mainly used for transporting fluid in high pressure discharge line, well testing line and cementing slurry line.

Integral Fittings are used for connection units in hard plumbing applications. Sino Mechanical offers a variety of high-pressure integral union configurations and pressure ratings in forged Integral Fittings.

Flexible Choke and Kill Lines are high pressure line that used for high temperature fluid circulation into and out of the wellbore to control well pressure.

Pressure Control equipment is safety equipment installed on a drilling rig with a complete set of special equipment, instruments and tools for implementing oil and gas well pressure control technology.

Sino Mechanical have all range of quality Pressure Control equipment, including BOP Staks, Annular BOP, Ram BOP, BOPs, Drilling Spools, Koomey units and multiplex control systems, as well as wellhead.

Pressure Control Equipment is an important mechanical process to keep the drilling fluids in their optimum parameters to perform operations safely and effectively.

Features of Pressure Control Equipment

1. Implement oil and gas well pressure control

2. Maintain drilling fluid at optimal parameters

3. Ensuring safe and efficient operations

4. Prevent the occurrence of blowout accidents and quickly achieve the effect of blowout prevention

5. Fast action, convenient operation, safe and reliable, and can be repaired on site

Function of Pressure Control Equipment

Pressure Control equipment is a set of special equipment, instruments and tools for pressure control technology, including Pressure Control wellheads, Pressure Control choke and kill manifolds, IBOP, drilling fluid gas separators, and automatic drilling fluid filling devices for tripping out etc. Combined with various monitoring devices and systems, the liquid level of the circulation tank is monitored and alarmed to ensure the normal circulation of the drilling fluid and prevent the occurrence of accidents in the tank, which will cause environmental pollution.

The function of Pressure Control equipment is to prevent the occurrence of blowout accidents, make the pressure of the wellbore fluid column greater than the pressure at the bottom of the well, and prevent the fluid in the well from ejecting from the wellhead, which will affect the smooth progress of oil drilling. When the overflow is found in time and there is a sign of blowout, take measures to shut down the well immediately to prevent accidents. The blowout can be quickly controlled to prevent serious out-of-control blowout accidents. To deal with complex oil drilling accidents, if there is a serious out-of-control blowout, fire extinguishing and other operations can be started to prevent the accident from expanding and causing huge economic losses to oil drilling.

1. Solve the safety problems of oil drilling.

2. Promote the improvement of oil drilling construction quality.

3. Prevent blowout, find overflow in time, and quickly control blowout. Conducive to the safe and smooth completion of oil drilling tasks.

Application of Pressure Control Equipment

The application of Pressure Control equipment has a higher safety factor than conventional oil drilling equipment, so as to avoid the occurrence of various safety accidents at all levels. Through the application of Pressure Control equipment, the overflow of the wellhead can be found in time, and the control measures can be implemented to prevent the occurrence of blowout accidents.

born. Therefore, in the process of oil drilling construction, it is necessary to ensure the normal operation of Pressure Control equipment and strengthen the maintenance of Pressure Control equipment in order to improve the operating efficiency of Pressure Control equipment, better complete Pressure Control management tasks, and improve the quality of oil drilling construction.

1. As a wellhead device for Pressure Control, it can quickly achieve the effect of blowout prevention. The action is fast, the operation is convenient, safe and reliable, and it can carry out on-site maintenance and reduce the risk of accidents.

2. The action time of the ring-shaped wellhead blowout preventer does not exceed 30s, the action time of the ram blowout preventer is 3~8s, and the time to open the hydraulic blowout valve is only 3s, which reaches the state of emergency response and avoids excessive pressure in the well. high, causing serious safety accidents.

3. The switches of the wellhead blowout preventers are operated by hydraulic pressure, which belongs to hydraulic or pneumatic control, without human intervention, and the effect is more prominent. If the ram of the ram blowout preventer is broken, or the rubber core is broken, it can be repaired on site, which is simple and feasible, and can promote the effect of wellhead blowout prevention.

4. Reasonably select the hydraulic blowout preventer to ensure safe and reasonable drilling of the wellbore. According to the actual situation of the drilled wellbore, the hydraulic blowout preventer is selected to ensure the condition of balanced drilling, save the cost of oil drilling, and meet the needs of low-cost drilling construction.

The main factors to be considered in selecting a blowout preventer combination are: well type, formation pressure, casing size, formation fluid type, technical status of personnel, technological requirements, climate impact, traffic conditions, material supply status and environmental protection requirements, etc. In short, it should be able to achieve balanced drilling, ensure drilling safety and save drilling costs.

5. Choice of pressure level

The working pressure of the hydraulic blowout preventer combination depends on the internal pressure resistance of the casing used, the fracture pressure of the open hole formation at the casing shoe and the expected maximum wellhead pressure. But it is mainly determined according to the maximum wellhead pressure that the blowout preventer combination is expected to withstand. There are five types of blowout preventer pressure levels: 14MPa, 21 MPa, 35MPa, 70MPa, 105MPa, 140MPa.

6. Selection of diameter

The diameter of the blowout preventer assembly depends on the casing size in the design of the wellbore structure, that is, it must be slightly larger than the outer diameter of the connected casing. There are nine kinds of BOP diameters: 180mm, 230mm, 280mm, 346mm, 426mm, 476mm, 528mm, 540mm, 680mm. Among them, 230mm, 280mm, 346mm, and 540mm are commonly used on site.

7. Choice of combination form

The choice of combination form is mainly based on formation pressure, drilling process requirements, different diameters of drilling tools and equipment matching conditions.

Inspection and Maintenance of Pressure Control Equipment

1. In order to improve the efficacy of drilling Pressure Control equipment, regular inspection and maintenance should be carried out to improve the operating efficiency of Pressure Control equipment and achieve the expected Pressure Control effect. Check and maintain the blowout preventer group for Pressure Control, check whether the blowout preventer group is in a normal switch state, the fastening condition of each part, inspect and maintain the parts of the blowout preventer, replace the sealing rubber core in time, and improve Sealing performance. Check the connection of the blowout prevention pipeline and the blowout pipeline. Welding and leakage are not allowed. If the pipeline problems are found, they should be dealt with in time to ensure the normal operation of various manifolds, so as to achieve the effect of Pressure Control.

2. Check and pressure test the choke manifold and kill manifold, if any connection problems are found, fasten them immediately to ensure the normal connection of various manifolds. And check and maintain the integrity of the mud gas separator to prevent the existence of excessive gas,

And cause explosion accident, influence the smooth progress of oil drilling. The safety valve of the gas separator operates safely to achieve the state of gas separation, so that the liquid separated by the gas separator can enter the mud pool normally, providing assistance for the normal circulation of drilling fluid.

3. Check and maintain the remote console, check the operation of various instruments, collect and record drilling construction data in real time, discover potential safety hazards in time, and prevent various safety accidents. On-site commissioning of various Pressure Control equipment,

After the pressure test operation, the sealing conditions of various manifolds can be accurately judged, and the normal operation of various control systems can be confirmed, so as to ensure the safety of the whole process of oil drilling construction.

Pressure Control Equipment Consist of

BOP Stacks

Annular BOP

Double Ram BOP

Single Ram BOP

Coiled Tubing BOP

BOP Control Systems

Drilling Spools

Choke Manifold

Kill Manifold

Choke Lines

Hose Lines

Gate Valve

Casing Head

Tubing Head

Wellheads

IBOP

Float Valve

Kelly Valve

Pressure Control Equipment Supplier

Sino Mechanical has more than 20 years extensive experiences in the performance, application and cost-effective manufacturing of Pressure Control Equipment. We are global Pressure Control Equipment manufacturer and drilling equipment supplier. We offer a wide range of drilling equipment. Sino Mechanical is an exclusive supplier of leading Oil and Gas equipment manufacturers and we also provide OEM services. We design, manufacture, and sell Pressure Control Equipment for your drilling applications. If you are looking for Pressure Control Equipment or Pressure Control Equipment components, don’t hesitate to contact us anytime. We will get back to you within 24 hours.