Description

Overview of Screw Pumps

The screw pump is a displacement rotor pump, which relies on the volume change of the sealed cavity formed by the screw and the bushing to suck and discharge the liquid. Screw pumps are divided into single screw pumps, double, three and five screw pumps according to the number of screws. The screw pump is characterized by stable flow, small pressure pulsation, self-priming ability, low noise, high efficiency, long life and reliable operation. And its outstanding advantage is that no eddy current is formed when conveying the medium. It is not sensitive to the viscosity of the medium and can transport high-viscosity medium.

A screw pump uses one or more screws to move fluids or water along the axis of the screw. These screws are meshed with each other and reciprocate in the cavity of the cylinder.

For applications involving the transfer of fuels, oils and other lubricating fluids, screw pumps and gear pumps are usually the pumping technology selected. As fluctuations in the thickness of a fluid affects the performance of a centrifugal pump much more than a positive displacement pump, screw pumps and gear pumps are generally the most efficient solutions for oils and fuels.

As a global supplier of screw pumps, Sino Mechanical delivers screw pumps with superior self-priming capabilities, providing excellent performance in the most demanding applications regardless of temperature, viscosity, or pressure. These pumps operate quietly, exhibit minimal pulsation, and involve little fluid agitation, making them well-suited for use with corrosive and non-corrosive, low or high viscosity, as well as clean or abrasive liquids.

Features of Screw Pumps

1. Stable operation: uniform flow, stable pressure, and good variable adjustment.

2. Reliable sealing: hard alloy seals made of different materials. This guarantees leak-free delivery of different media.

3. Low noise: use low-noise bearings to run smoothly. Except for the faint sound of the motor, there is basically no noise.

4. Low failure rate: simple and reasonable structure. The key parts adopt advanced manufacturing technology and reliable materials, and the trouble-free working time of the whole machine is greatly improved.

5. Easy maintenance: simple structure, easy to assemble and disassemble. Product-related parts can be cleaned directly, and there is no dead angle in the flow-through part.

6. Easy installation: The multi-directional combination of inlet and outlet is convenient for pipeline layout and installation, which is more in line with the needs of the site.

7. Using synchronous gear transmission. Rotating parts do not touch each other. The bearing is external, lubricated independently, and not affected by the medium.

8. It has a strong self-priming ability, and can transport gas-liquid mixture.

Applications of Screw Pumps

1. Environmental protection: Transportation of industrial sewage, domestic sewage, sludge and dirty water containing solid particles and short fibers.

2. Shipbuilding industry: wheel bottom cleaning, transportation of oily water, oil residue, oily sewage and other media.

3. Transportation of crude oil, residual oil, fuel oil, oil slurry and asphalt in oil drilling and transportation.

4. Transportation of various high-viscosity oil products in petroleum refineries.

5. Transportation of various suspensions, oils, various colloidal pulps, viscose pastes, emulsions, and various ointments in the chemical and pharmaceutical industries.

6. Delivery of various lubricating oils.

Types of Screw Pumps

1. According to the number of screws:

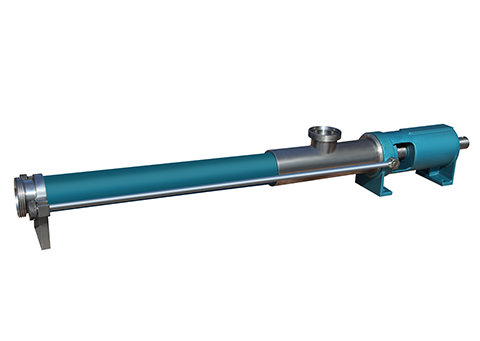

1) Single screw pump - a pump in which a single screw engages and rotates in an internal thread groove in the pump body.

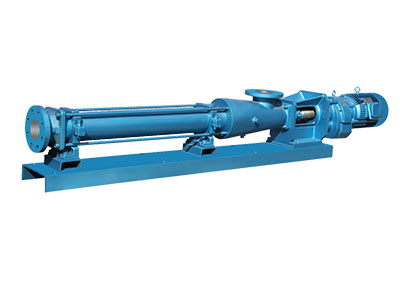

Single-screw pump: Single-screw pump is a kind of single-screw transport pump. Its main working parts are the screw bushing (called stator) of the screw (called rotor) and the inner surface of the eccentric spirochete and the double-wire helicoid. Its working principle is that when the motor drives the pump shaft to rotate, the screw rotates around its own axis on the one hand, and rolls along the inner surface of the bush on the other hand. A sealed chamber of the pump is then formed. Every time the screw rotates one revolution, the liquid in the sealed cavity advances one pitch forward. With the continuous rotation of the screw, the liquid is pressed from one sealed cavity to the other in a spiral manner. Finally squeeze out the pump body.

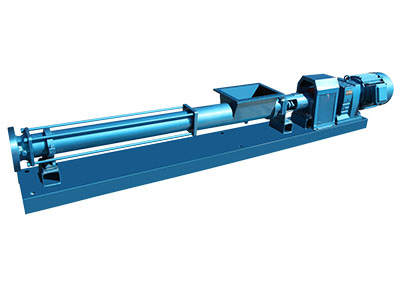

2) Twin-screw pump - a pump in which two screws mesh with each other to deliver liquid.

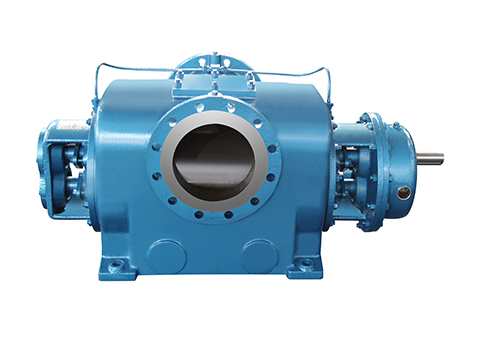

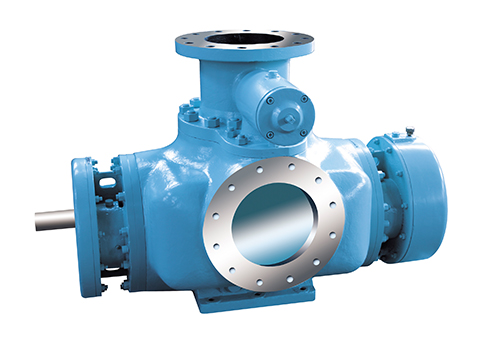

Twin-screw pump is an externally meshing screw pump, which uses two screws that mesh with each other and do not touch each other to pump liquid. As a double-suction non-hermetic twin-screw pump. The driving screw with one end protruding out of the pump is driven by the prime mover. The driving screw and the driven screw have threads with different directions of rotation, and the screw is closely attached to the pump body. The driven screw is driven by the driving screw through the synchronous gear. The suction chamber in the pump should be tightly separated from the discharge chamber. Therefore, the clearance between the pump body and the outer surface of the screw and the gap between the screw and the screw should be as small as possible. At the same time, the screw and the pump body, and the screw and the screw form a sealed cavity to ensure airtightness, otherwise liquid may flow back from the gap.

3) Multi-screw pump - a pump in which multiple screws mesh with each other to deliver liquid.

2. According to the screw suction method:

1) Single suction type Screw Pumps: the medium is sucked in from one end of the screw and discharged from the other end.

2) Double suction type Screw Pumps: the medium is sucked from both ends of the screw and discharged from the middle.

3. According to the position of the pump shaft:

1) Horizontal screw pump

2) Vertical screw pump

Efficiency of Screw Pumps

Price of Screw Pumps

The Screw Pumps Price will change randomly with factors such as production cost, transportation cost, international situation, exchange rate, market supply and demand of raw materials. Sino Mechanical aims to provide you with high quality and best price Screw Pumps. If you are looking for Screw Pumps, please kindly contact us to get the latest Screw Pumps price.

Screw Pumps Supplier

Sino Mechanical, as a Screw Pumps manufacturer, has more than 20 years extensive experiences in the performance, application and cost-effective manufacturing of Screw Pumps. We are global Screw Pumps supplier. We offer a wide range of oilfield equipment and have Screw Pumps for sale. We also provide OEM services. We design, manufacture, and sell Screw Pumps for your drilling applications. If you want to know latest Screw Pumps price, don't hesitate to contact us anytime. We will get back to you within 24 hours.

Sino Mechanical has delivered high-performance screw pumps and technical solutions to users in the Asia-Pacific, Middle East, North Africa, Europe, and other regions and countries. We ensure competitive pricing and swift delivery of our products.

Specification

Sino Mechanical Screw Pump

The screw pump of Sino Mechanical meet the advanced industry standards and can be used in the petrochemical industry. Sino Mechanical Screw Pump provides ideal pumping solutions for customers in the petroleum industry, which can be used in the upstream mining stage, large-scale crude oil transportation, sewage treatment systems, cargo oil loading and unloading, pressurization systems in the midstream storage and transportation stage, and industrial processes in the downstream smelting stage , Oil loading and unloading, sewage treatment system. Sino Mechanical Screw Pump has established a long-term and stable cooperative relationships with large oil companies.

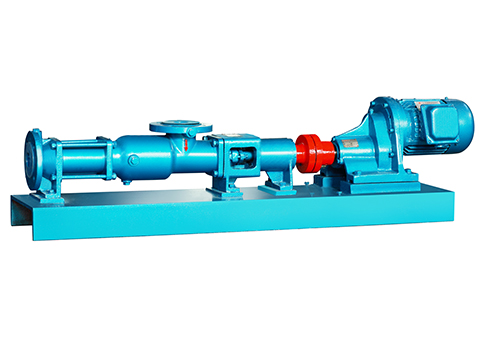

1. Single Screw Pump

(1) G series - general purpose pump

Features:

G series single screw pump is installed horizontally and connected by flange.

The profile design is characterized by small eccentricity, medium lead, improved bushing life, long sealing line, and reduced leakage.

The leads of the bushings of different stages are unchanged. Only the length of the bushing is changed. And the suction capacity of the pumps of different stages remains unchanged.

Performance Range:

Greatest pressure:

Single-stage 0.6MPa. Two-stage 1.2 MPa. Three-stage 1.8MPa

Maximum flow: 130m3/h

Maximum viscosity: 2.7*105cSt

Allowable maximum temperature: 150°C

Applications:

It can transport liquid containing fiber and solid particles, or medium containing gas. It is widely used in food, petroleum, chemical, shipbuilding, textile and other industries as delivery pumps.

(2) EHN series - backpack type single screw pump

Features:

EHN series backpack type single screw pump is installed horizontally and connected by flange.

The EH series general-purpose pump head is adopted. The axial dimension is shortened, and accessories such as anti-dry running device and safety valve can be added according to user needs.

Performance Range:

Greatest pressure:

Single-stage 0.6MPa. Double-stage 1.2 MPa. Three-stage 1.8 MPa. Four-stage 2.4 MPa

Maximum flow: 300m3/h

Maximum viscosity: 2.7*105cSt

Allowable maximum temperature: 150°C

Applications:

Widely used in petroleum, chemical, shipbuilding and other industries.

(3) GN series—backpack type single screw pump

Features:

GN series backpack type single screw pump is installed horizontally and connected by flange.

The design feature is the use of G series general-purpose pump heads, which shortens the axial dimension. And it can add anti-dry running devices, safety valves and other accessories according to user needs.

Performance Range:

Greatest pressure:

Single-stage 0.6MPa. Double-stage 1.2 MPa

Maximum flow: 130m3/h

Maximum viscosity: 2.7*105cSt

Allowable maximum temperature: 150°C

Applications:

It can transport liquid containing fiber and solid particles, or medium containing gas. It is widely used as a delivery pump in shipbuilding, petroleum, chemical and other industries.

(4) EU series—vertical pump

Features:

The EU series is installed vertically. To meet special needs, the universal joint shaft is lengthened and equipped with a vertical pump body.

The pump can be installed directly on the well container to be pumped, or fixed on a wall. And the delivery element is immersed in the medium.

Performance Range:

Greatest pressure:

Single-stage 0.6MPa. Double-stage 1.2MPa.

Maximum flow: 100m3/h

Maximum viscosity: 2.7*105cSt

Allowable maximum temperature: 150°C

Applications:

It is used to transport viscous and non-viscous media, or media containing solid particles or fibers, such as wastewater treatment, sedimentation tank slag, etc.

(5) ES series—food and medicine pump

Features:

The ES series is a quick-change pump, which is developed from the H basic type. The difference lies in the pump body, which is tightened by two tie rods fixed on the bearing body. The inlet and outlet have special arc threads for quick disassembly.

Performance Range:

Greatest pressure:

Single-stage 0.6MPa. Double-stage 1.2MPa.

Maximum flow: 60m3/h

Maximum viscosity: 2.7*105cSt

Allowable maximum temperature: 150°C

Applications:

Widely used in various industrial fields

(6) EL series—compact pump

Features:

EL series backpack type single screw pump is installed horizontally and connected by flange.

The EH series general-purpose pump head is adopted, the axial dimension is shortened, and accessories such as anti-dry running device and safety valve can be added according to user needs.

Performance Range:

Greatest pressure:

Single-stage 0.6MPa. Double-stage 1.2 MPa. Three-stage 1.8 MPa. Four-stage 2.4 MPa

Maximum flow: 300m3/h

Maximum viscosity: 2.7*105cSt

Allowable maximum temperature: 150°C

Applications:

Widely used in petroleum, chemical, shipbuilding and other industries.

(7) MEH type single screw pump

Features:

The MEH series is horizontal installation and flange connection.

The MEH series is a multi-head single screw pump. Its main pumping elements are composed of a rotating rotor and a fixed stator. The conveyed medium will not be stirred, squeezed and sheared.

Compared with conventional single-head screw pumps, MEH series multi-head single-screw pumps have the following advantages:

①. With the same size pump at the same speed, the flow rate of the MEH pump is increased by 50%, and the pressure is increased by 30%.

②. Under the same flow rate, the overall size of the MEH pump is reduced, saving installation space.

③. Since the eccentricity of the MEH pump is reduced, the friction speed of the rotor in the stator is reduced, which prolongs the life of the rotor/stator.

④. The number of liquid chambers discharged by the MEH pump increases to six per revolution, the flow and pressure fluctuations are very small, and the performance of the pump is very stable.

⑤. The efficiency of the MEH pump is improved.

Performance Range:

Greatest pressure:

Single-stage 0.8MPa; two-stage 1.6 MPa; three-stage 2.4 MPa

Maximum flow: 400m3/h

Maximum viscosity: 2.7*105cSt

Allowable maximum temperature: 150°C

Applications:

It is widely used in various industries such as petroleum, chemical industry, shipbuilding, food and textile.

(8) EP series - high pressure small flow pump

Features:

The ER series is developed on the basis of the EH series, with a pump body with a special inlet and a coupling shaft with a screw propulsion.

Its performance parameters are the same as those of the EH series of the same specification, but the pumping medium is high viscosity, and the power of the selected motor should be appropriately enlarged.

Performance Range:

Greatest pressure:

Single-stage 0.6MPa; double-stage 1.2 MPa; four-stage 2.4 MPa

Maximum flow: 120m3/h

Maximum viscosity: 1*107cSt

Allowable maximum temperature: 150°C

Applications:

It is used to convey high-viscosity pasty and difficult-to-pump media or media containing solid substances.

(9) ER series - non-flow material pump

Features:

The ER series is developed on the basis of the EH series, with a pump body with a special inlet and a coupling shaft with a screw propulsion.

Its performance parameters are the same as those of the EH series of the same specification, but the pumping medium is high viscosity, and the power of the selected motor should be appropriately enlarged.

Performance Range:

Greatest pressure:

Single-stage 0.6MPa; double-stage 1.2 MPa; four-stage 2.4 MPa

Maximum flow: 120m3/h

Maximum viscosity: 1*107cSt

Allowable maximum temperature: 150°C

Applications:

It is used to convey high-viscosity pasty and difficult-to-pump media or media containing solid substances.

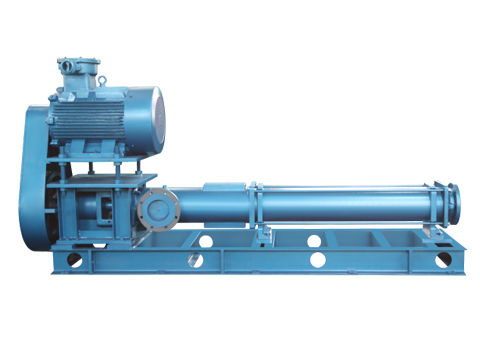

(10) EH type single screw pump

Features:

EH series is horizontal installation, flange connection

The profile design is characterized by large eccentricity, large lead, improved bushing life, long sealing line, and reduced leakage.

The length of the bushes of different stages is the same, only the lead is changed, and the installation dimensions of the pumps of different stages remain unchanged.

Performance Range:

Greatest pressure:

Single-stage 0.6MPa; double-stage 1.2 MPa; three-stage 1.8 MPa; four-stage 2.4 MPa

Maximum flow: 300m3/h

Maximum viscosity: 2.7*105cSt

Allowable maximum temperature: 150°C.

Applications:

Widely used in petroleum, chemical industry, shipbuilding, food, textile and other industries.

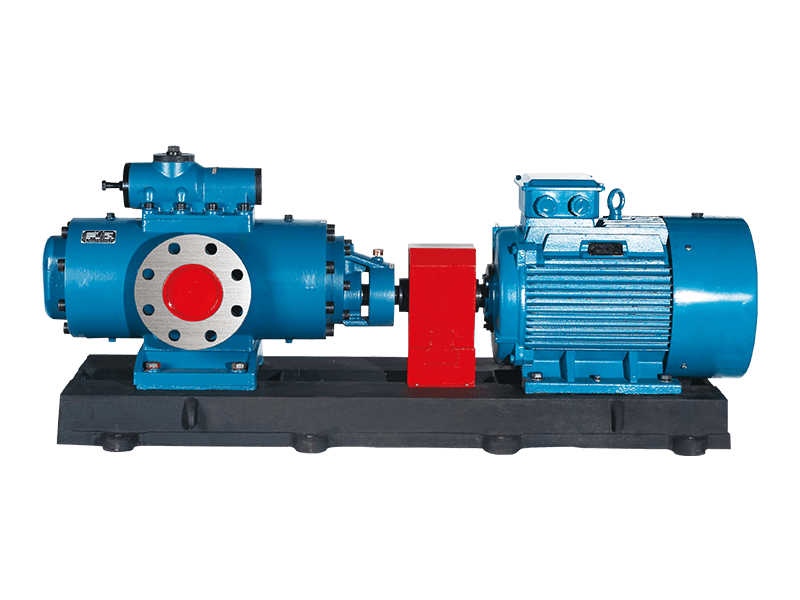

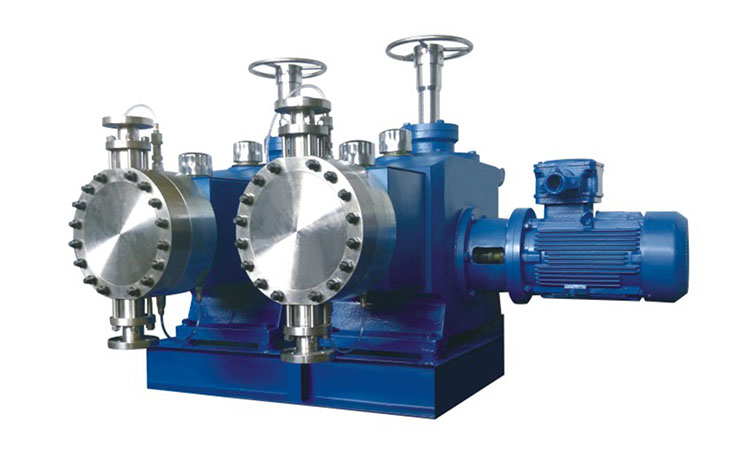

2. Twin-screw pump

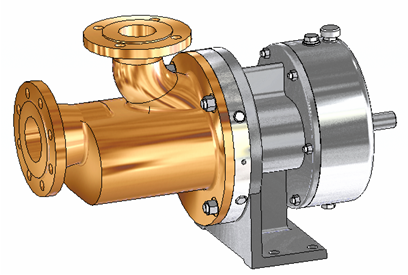

(1) W.Kse series twin-screw pump

Features:

Single suction structure, compact structure, and small volume.

W.Kse series twin-screw pumps can be quickly disassembled and cleaned.

Performance Range:

Flow Q: ~40 m3/h

Temperature t: 120℃

Pressure difference △P: 1.2MPa

Applications:

W.Kse series twin-screw pumps are widely used in chemical industry, paint, beverage, pharmaceutical, food, etc.

(2) G series twin screw pump

Features:

The inlet and outlet of the pump are on the same level.

Ultra-short shaft, double-suction structure, and the pump body is welded.

Performance Range:

Flow Q: ~550 m3/h

Temperature t: 80~150℃

Pressure difference △P: ~1.4MPa

Applications:

G series twin-screw pumps are widely used as conveying pumps in various industries such as shipbuilding, petroleum, chemical industry, oil fields, and thermal power plants.

(3) U series twin screw pump

Performance Range:

Flow Q: 40~1000 m3/h

Temperature t(max): 80℃

Pressure difference △P: ~1.0MPa

Applications:

U series twin-screw pumps are mainly used in shipbuilding industry as deep well cargo oil pumps.

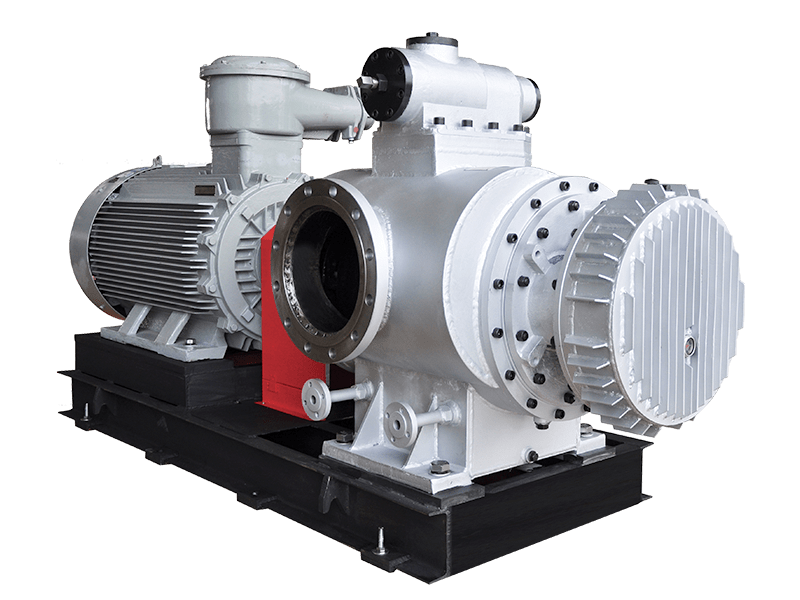

(4) HW series twin screw pump

Features:

Horizontal installation, flange connection.

The special structural design makes the pump have a strong dry running capability.

When the inlet air content of the pump fluctuates within the range of 0~100%, the mixed pump can work stably.

Performance Range:

Flow Q: ~2000 m3/h

Suction pressure: ~2.0Mpa

Discharge pressure: ~5.0Mpa

Sand content: ≤ 2%

The gas content rate reaches 98%, and the dry running time of 100% gas: 30~40 minutes.

Applications:

HW series twin-screw pumps are used for the delivery of multiphase flow. Applied to land oilfields, offshore oilfields, and marginal oilfields.

(5) HPW series twin-screw pump

Features:

Horizontal installation, flange connection.

Ultra-short shaft, double-suction structure, and the pump body is welded.

Performance Range:

Flow Q: ~1000 m3/h

Temperature t(max): 100℃

Pressure difference △P: ~10.0MPa

Applications:

It is mainly used in petroleum, chemical industry, wharf, pump station, etc., as a long-distance high-pressure delivery pump, which can deliver fluids of various viscosities.

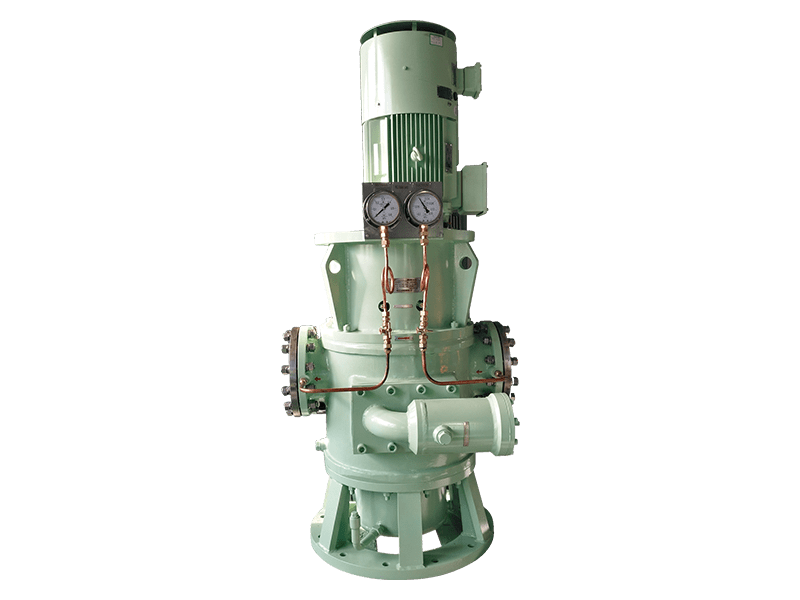

(6) SV series twin screw pump

Features:

Vertical installation, flange connection.

Strong self-priming ability

Low noise, no pulsation, no emulsification and shearing effect on the medium

Performance Range:

Flow Q: ~1800 m3/h

Temperature t: -20℃~300℃

Pressure difference △P: ~1.6MPa

Applications:

It is suitable for conveying lubricating and non-lubricating liquids, and is widely used in oil fields, petrochemicals, shipbuilding, thermal power plants, food, paint and other industries.

(7) V series twin screw pump

Features:

Vertical installation, flange connection.

Strong self-priming ability

Low noise, no pulsation, no emulsification and shearing effect on the medium

Performance Range:

Flow Q: ~1200 m3/h

Temperature t: -20℃~300℃

Pressure difference △P: ~2.5MPa

Applications:

Suitable for conveying lubricating and non-lubricating liquids. Widely used in oil fields, petrochemicals, shipbuilding, thermal power plants, food, paint and other industries.

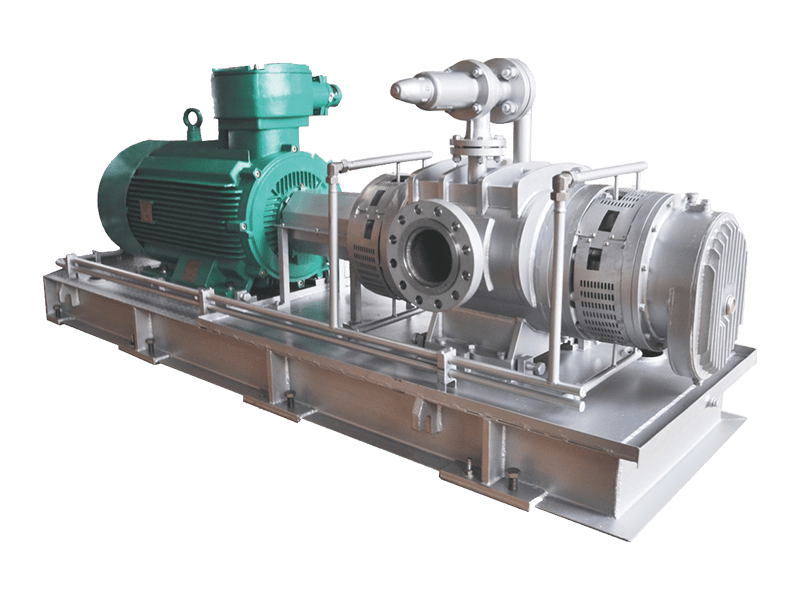

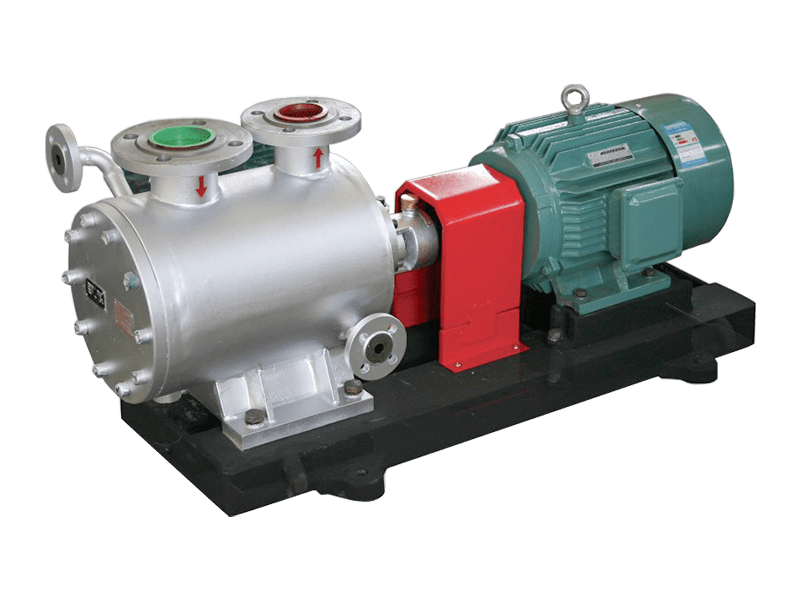

(8) SW series twin screw pump

Features:

Horizontal installation, flange connection.

Strong self-priming ability

Low noise, no pulsation, no emulsification and shearing effect on the medium

It can transport gas and liquid mixed

Performance Range:

Flow Q: ~2700 m3/h

Temperature t: -20℃~350℃

Pressure difference △P: ~1.6MPa

Applications:

SW series twin-screw pumps are suitable for conveying lubricating and non-lubricating liquids. Widely used in oil fields, petrochemicals, shipbuilding, thermal power plants, food, paint and other industries.

(9) W series pump twin screw pump

Features:

Horizontal installation, flange connection.

Strong self-priming ability

Low noise, no pulsation, no emulsification and shearing effect on the medium

It can transport gas and liquid mixed

Performance Range:

Flow Q: ~2000 m3/h

Temperature t: -20℃~350℃

Pressure difference △P: ~6.0MPa

Applications:

W series pump twin-screw pump is suitable for conveying lubricating and non-lubricating liquids. Widely used in oil fields, petrochemicals, shipbuilding, thermal power plants, food, paint and other industries.

(10) twin screw pump

Features:

The twin-screw pump is self-priming, with good suction and small cavitation allowance. Wide delivery range. It can be mixed with gas and liquid. The flow pressure pulsation is small and the delivery is stable. Insensitive to medium and impurities. A variety of installation forms to meet the different needs of users.

conveying medium

Lubricating and non-lubricating fluids. Corrosive and non-corrosive fluids. Low viscosity fluids and high viscosity polymers. gaseous multiphase flow.

Performance Range:

Flow: max.2700m3/h

Differential pressure: max.10.0Mpa

Working temperature: max.350℃

Medium viscosity: max.1*105cSt

Cavitation allowance: min. 1.5m

Speed: max.1800rpm

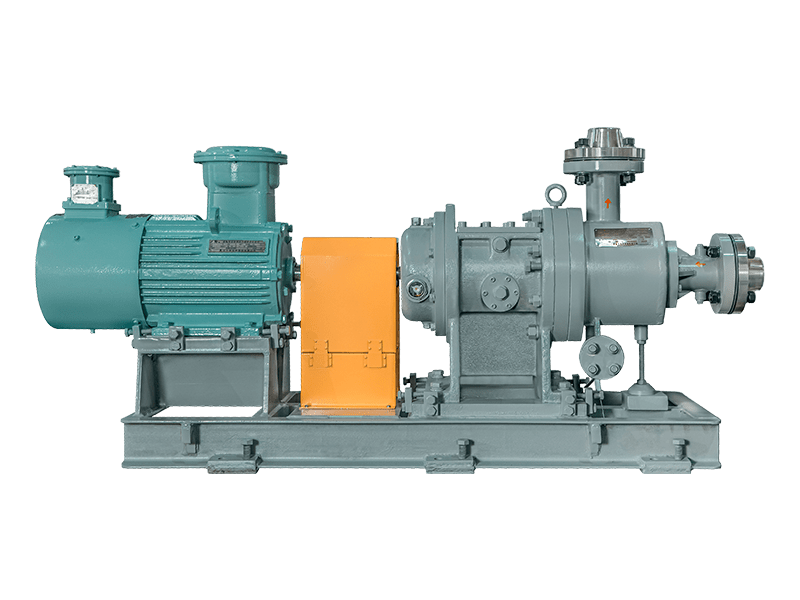

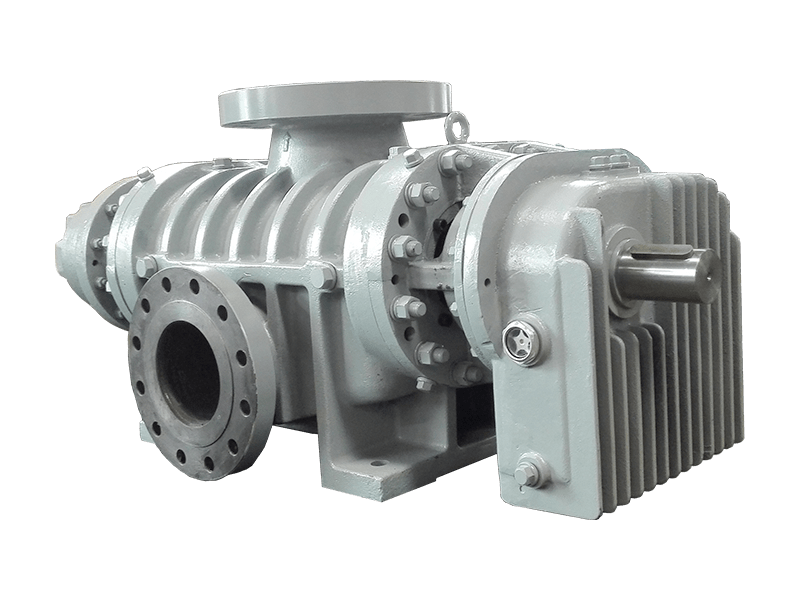

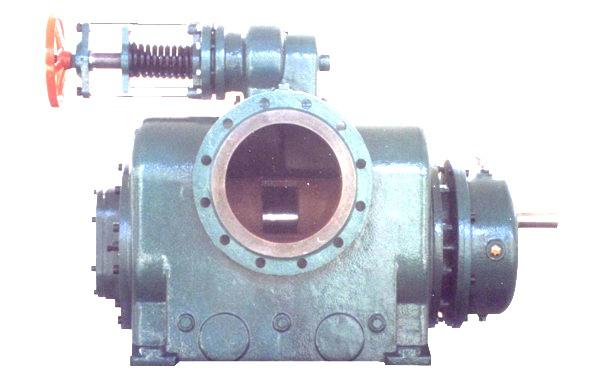

Three Screw Pump

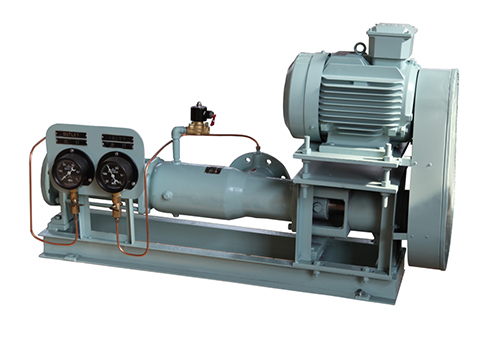

(1) SD series single suction high pressure small flow Three Screw Pump

Features:

It can be installed horizontally, vertically and oil-immersed through the connecting frame.

Performance Range:

Flow Q (max): 10m3/h

Pressure difference △P (max): ~21MPa

Speed (max): 3400r/min

Working temperature t(max): 80℃

Medium viscosity: 30~380cSt

Applications:

It is suitable for single suction, high pressure and small flow conditions.

(2) SE series single suction high pressure small flow Three Screw Pump

Features:

It can be installed horizontally, vertically and oil-immersed through the connecting frame.

Performance Range:

Flow Q (max): 3.1m3/h

Pressure difference △P (max): ~16MPa

Speed (max): 3400r/min

Working temperature t(max): 80℃

Medium viscosity: 20~380cSt

Applications:

It is suitable for single suction, high pressure and small flow conditions.

(3) SM series single suction medium pressure Three Screw Pump

Features:

Each pump has four installation forms: horizontal, flange, vertical and wall-mounted.

Single suction medium pressure series

Performance Range:

Flow Q (max): 200 m3/h

Pressure difference △P (max): ~10MPa

Speed (max): 3400r/min

Working temperature t(max): 150℃

Medium viscosity: 3~3750cSt

Applications:

The design pressure is 10MPA, and the SN series is selected when the working pressure cannot be met.

(4) SZ low pressure double suction series Three Screw Pump

Features:

There are two installation forms of vertical and horizontal.

Low pressure double suction series

Performance Range:

Flow Q: 16~550 m3/h

Pressure difference △P (max): ~1.6 MPa

Speed (max): 1750 r/min

Working temperature t(max): 80℃

Medium viscosity: 3~3750 cSt

Applications:

Double suction structure, suitable for low pressure and high flow conditions

(5) SF series single suction medium pressure small flow

Features:

It can be installed horizontally, vertically and oil-immersed through the connecting frame.

Performance Range:

Flow Q (max): 3.1m3/h

Pressure difference △P (max): ~10MPa

Speed (max): 3400r/min

Working temperature t(max): 80℃

Medium viscosity: 20~380cSt

Applications:

It is suitable for single suction, medium pressure and small flow conditions.

(6) SNHG series three-screw pump

Features:

Horizontal installation.

Performance Range:

Flow Q (max): 450 m3/h

Pressure difference △P (max): 4.5 MPa

Speed (max): 1450 r/min

Working temperature t(max): 150℃

Medium viscosity: 3~760 cSt

Applications:

It is a supplement to the SN series for large flow conditions.

(7) SD type three-screw pump

The high-pressure and large-flow three-screw pump is suitable for occasions that require high flow and pressure, such as long-distance crude oil transportation.

(8) SDH series three-screw pump

Features:

horizontal installation

High pressure single suction, small flow

Performance Range:

Flow Q (max): 60 m3/h

Pressure difference △P (max): ~16MPa

Speed (max): 2900r/min

Applications:

The design pressure is 16MPA, and the SN and SM series are selected when the working pressure cannot be met.

(9) SL type, 3GS/3GCS type, 3GN, 3GR, three-screw pump

The high-pressure and large-flow three-screw pump is suitable for occasions that require high flow and pressure, such as long-distance crude oil transportation.

(10) SN series single suction medium pressure Three Screw Pump

Features:

Each pump has four installation forms: horizontal, flange, vertical and wall-mounted.

Single suction medium pressure series

Performance Range:

Flow Q (max): 318 m3/h

Pressure difference △P (max): ~4.0MPa

Speed (max): 3400r/min

Working temperature t(max): 150℃

Medium viscosity: 3~3750cSt

Applications:

The design pressure is 4MPA, and the series is preferred under 4MPA.

How to choose a screw pump?

Screw pumps are widely used in sewage treatment plants to transport water, wet sludge and flocculant liquids because of their variable delivery, strong self-priming ability, reversibility, and ability to transport liquids containing solid particles. . The selection of screw pumps should follow the principles of economy, rationality and reliability. If the design and selection are not well thought out, it will cause troubles for future use, management, and maintenance. Therefore, choosing a reasonable and reliable screw pump according to the actual needs of production can not only ensure the smooth progress of production, but also reduce repair costs.

1. Selection of the speed of the screw pump

The flow rate of the screw pump has a linear relationship with the speed. Compared with the low-speed screw pump, the high-speed screw pump can increase the flow and head, but the power is significantly increased. The high speed accelerates the wear between the rotor and the stator, which will inevitably make the screw pump fail prematurely. Moreover, the length of the stator and rotor of the high-speed screw pump is very short, which is easy to wear. Thus shortening the service life of the screw pump.

The speed is reduced by a reduction mechanism or a stepless speed regulation mechanism. Keep its rotational speed within a reasonable range below 300 revolutions per minute. Compared with the high-speed screw pump, the service life can be extended several times.

2. The quality of the screw pump

There are many types of screw pumps.

When choosing a screw pump, it is necessary to consider the reasonable structure design and its cost performance. Choose products with low speed, long lead, high-quality transmission components and long rated life.