Description

Overview of Centrifugal Pumps

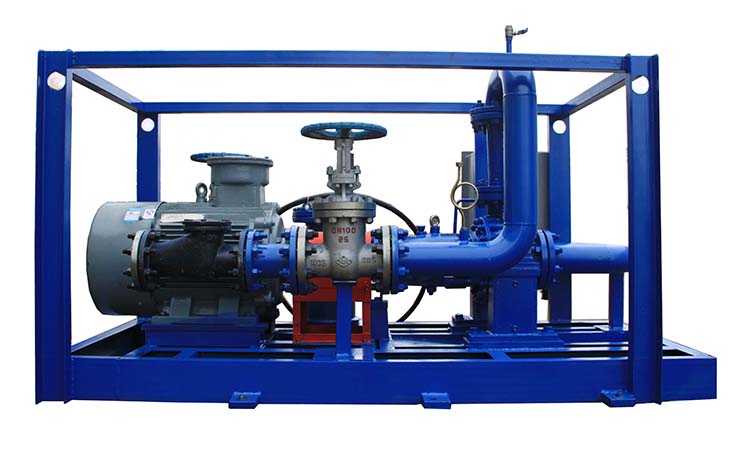

Centrifugal pumps are to transfer fluids through an increase in pressure. Sino Mechanical centrifugal pumps have a simple design that produces high efficiency to hande a diverse range of head and capacity while producing a high flow rate.

Features of Centrifugal Pumps

1. Centrifugal pumps are usually specified for higher flows and for pumping lower viscosity liquids, down to 0.1 cP.

2. The efficient operation of a centrifugal pump relies on the constant, high speed rotation of its impeller.

3. Centrifugal pump designs offer simple and low cost solutions to most low pressure, high capacity pumping applications involving low viscosity fluids such as water, solvents, chemicals and light oils. Typical applications involve water supply and circulation, irrigation, and the transfer of chemicals in petrochemical plants.

4. Centrifugal pumps are the most common type of pump used in industry, agriculture, municipal (water and wastewater plants), power generation plants, petroleum and many other industries.

5. Centrifugal Pumps are highly versatile. They are available in many different shapes and sizes to handle a wide variety of installations and requirements, whether you need your pump to be driven electrically or magnetically, to self-prime, to be able to handle sanitary fluids or to be big enough for large industrial applications, there is a centrifugal pump solution available.

6. An additional key feature of a centrifugal pump is that it can be easily modified to suit different requirements for the end-user. For example, accessories can be used such as heating jackets, self-priming chambers and hygienic shrouds to achieve the perfect pump solution.

Applications of Centrifugal Pumps

Applicable Medium of Centrifugal Pumps : Clean water, sewage, sea water, petroleum, gasoline, diesel, heavy oil, LPG, chemical liquid, etc.

Centrifugal pumps are commonly used for pumping water, solvents, organics, oils, acids, bases and any "thin" liquids in both industrial, agricultural and domestic applications. In fact, there is a design of centrifugal pump suitable for virtually any application involving low viscosity fluids.

Sino Mechanical Centrifugal Pumps can be used in a wide range of sectors for a variety of applications, some of the most common applications we supply for include as per below (but are not limited to):

1. Fire protection, water supply and drainage, water treatment

2. Oilfield crude oil transportation, liquid rejection, oil depot transportation of various oil products

3. Petroleum refining

4. Chemical industry, medicine

5. Metallurgy, electric power, etc.

6. Heavy-duty industrial applications

What are the Advantages of Centrifugal Pumps?

1. Smooth Flow – Centrifugal flow is laminar and non-pulsating allowing them to be used with flowmeters easily.

2. Low Maintenance & Easy to maintain - Due to their simple uncomplicated design, which are often maintained without special tools or equipment.

3. Efficient – As the internal elements are free to rotate, they are very efficient when handling low viscosity fluids

4. Versatile – They can be designed to handle a multitude of liquids and solids by changing the materials of certain parts, or impeller design.

5. Low Cost – Due to their simplicity of design and wide availability, they are one of the lowest initial costs of pump. If specified correctly they can also provide the lowest lifetime cost for an application.

6. Low Infrastructure costs – As Centrifugal pumps can be ran against a closed valve for short periods without damage, additional accessories such as pressure relief valves and other devices are not required.

Components of Centrifugal Pumps

1. Shaft

2. Impeller

3. Casing

4. Suction Pipe

5. Delivery Pipe

Types of Centrifugal Pumps

1. Single-stage Centrifugal Pump

2. Multi-stage Centrifugal Pump

3. Horizontal Centrifugal Pump

4. Vertical Centrifugal Pump

5. Single-suction Centrifugal Pump

6. Double-suction Centrifugal Pump

7. Self-priming Pump

Price of Centrifugal Pumps

The Centrifugal Pumps Price will change randomly with factors such as production cost, transportation cost, international situation, exchange rate, market supply and demand of raw materials. Sino Mechanical, as one of a Centrifugal Pump manufacturers aims to provide you with high quality and best price Centrifugal Pumps. If you are looking for Centrifugal Pumps, please kindly contact us to get the latest Centrifugal Pumps price.

Centrifugal Pumps Supplier

Sino Mechanical, as one of global Centrifugal Pumps Companies, has more than 20 years extensive experiences in the performance, application and cost-effective manufacturing of Centrifugal Pumps. We are global Centrifugal Pumps supplier and Centrifugal Pumps company. We have Centrifugal Pumps for sale. If you are looking for Centrifugal Pumps, don’t hesitate to contact us anytime. We will get back to you within 24 hours.

Specification

Technical Specifications of Centrifugal Pumps

1. Flow rate - the amount of liquid (volume or mass) flowing through a certain section per unit time. Expressed with Q. The units are: m3/h, m3/s, l/min.

2. Head - the increase in energy per unit mass of liquid being transported from the pump inlet to the outlet. Represented by H. The unit is: MPa, m.

3. Speed - the number of revolutions of the shaft per unit time. Use n to represent. The unit is: r/min.

4. Equipped power - the rated power of the prime mover. Represented by N. The unit is: kW.5. Shaft power - the power transmitted from the prime mover to the pump shaft. Expressed with P. The unit is: kW.

6. Effective power - also known as output power, the effective energy obtained in the pump by the liquid delivered from the pump per unit time. Expressed in Pa. The unit is: kW.

7. Efficiency - the ratio of effective power to shaft power. Expressed with n.

9. NPSH - the excess energy (expressed in meters of liquid column) of the unit mass of liquid at the suction inlet of the pump exceeding the vaporization pressure of the liquid. Expressed in NPSH. The unit is: m.

10. Necessary NPSH - the NPSH determined according to the test (measured in meters of liquid column). Expressed in NPSHr. The unit is: m. The pump NPSH is determined by the characteristics of the pump itself, and is a parameter indicating the anti-cavitation performance of the pump itself. In order to improve the anti-cavitation performance of the pump itself, the NPSH must be reduced as much as possible.

11. Suction vacuum height - also known as suction vacuum degree, the vacuum degree of the suction port calculated from the pump reference plane (measured in meters of liquid column). Expressed with Hs. The unit is: m.

Types of Sino Mechanical Centrifugal Pumps

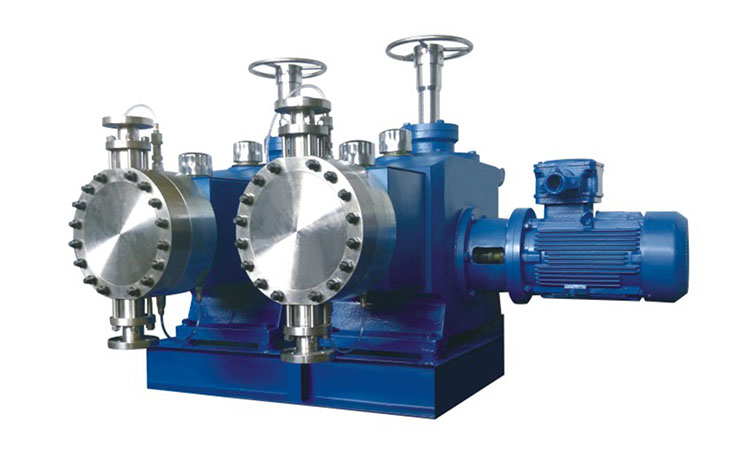

1. OH1 type centrifugal pump - ZAK series

ZAK series centrifugal pumps are OH1 horizontal cantilever, foot-supported, single-stage, radially split chemical process pumps in API 610 standard. It is widely used in the oil and gas and petrochemical industries.

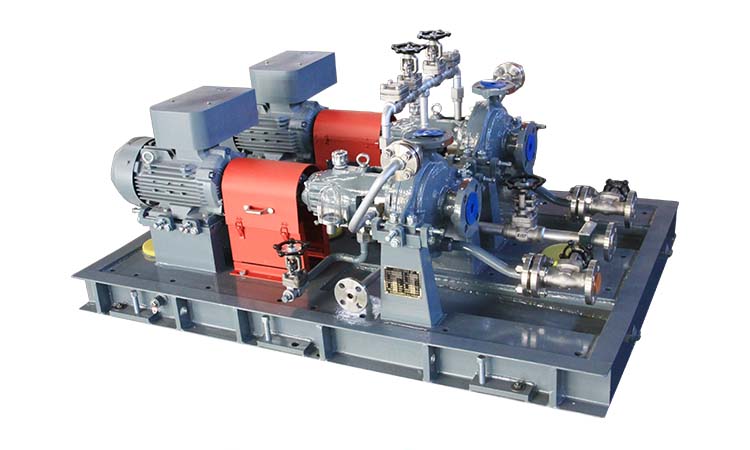

2. OH2 Centrifugal Pump——ZEK Series

This series of Centrifugal Pump are OH2 type horizontal cantilever, centrally supported, single-stage, radially split chemical process pumps in API 610 standard. Widely used in oil and gas and petrochemical industries.

3. OH1 type centrifugal pump - ZAK series

This series of products are OH1 horizontal cantilever, centrally supported, single-stage, radially split chemical process pumps in API 610 standard. It is suitable for conveying liquids such as low-temperature or high-temperature petrochemical, petrochemical products in the chemical industry, organic compounds, and acids, alkalis, and salt solutions of various temperatures and concentrations. At the same time, it can also transport neutral or organic corrosive liquids, and liquids containing solid particles.

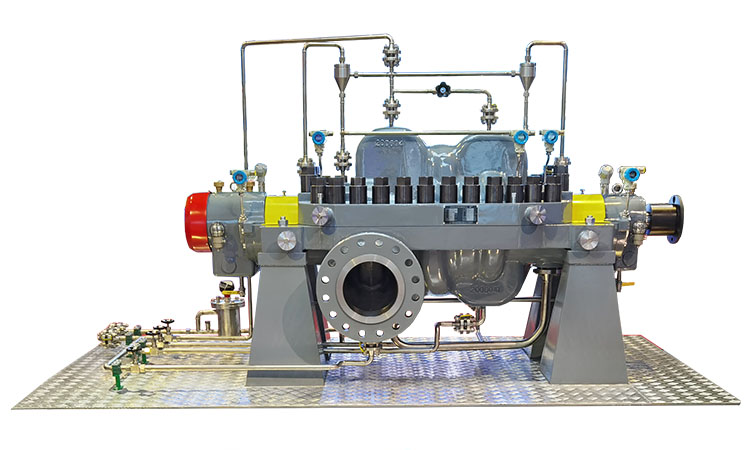

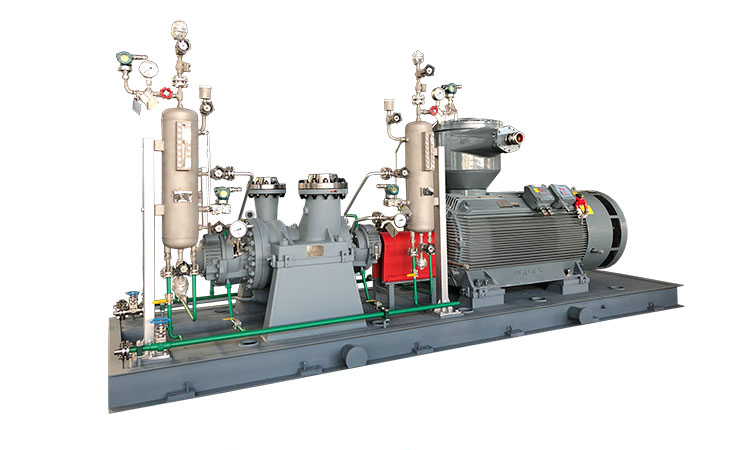

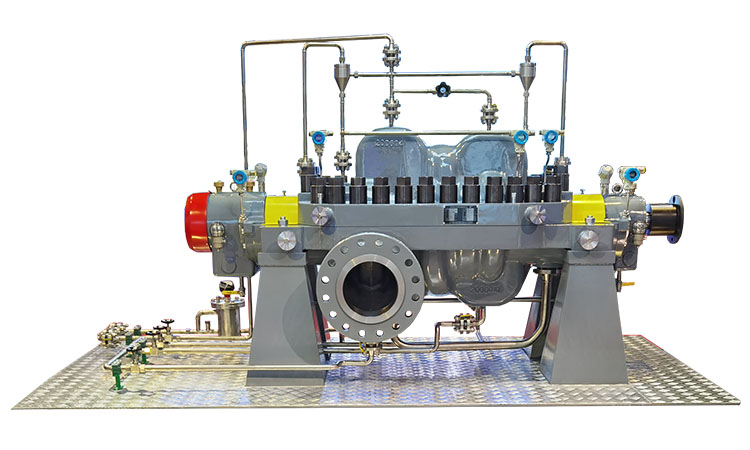

4. BB2 centrifugal pump——AY two-stage centrifugal pump

BB2 centrifugal pump is designed and developed in accordance with API Std 610 "Centrifugal Pumps for Petroleum, Petrochemical and Natural Gas Industries". It is an updated product centered on energy saving. It is suitable for petroleum refining, petrochemical and chemical industries and other transportation of petroleum and liquefied petroleum gas without solid particles. At the same time, the BB2 centrifugal pump is also suitable for low temperature, high temperature and corrosive media.

5. BB2 centrifugal pump——AY two-stage centrifugal pump

BB2 centrifugal pump is designed and developed in accordance with API Std 610 "Centrifugal Pumps for Petroleum, Petrochemical and Natural Gas Industries". It is an updated product centered on energy saving. It is suitable for petroleum refining, petrochemical and chemical industries and other transportation of petroleum and liquefied petroleum gas without solid particles. At the same time, the BB2 centrifugal pump is also suitable for low temperature, high temperature and corrosive media.

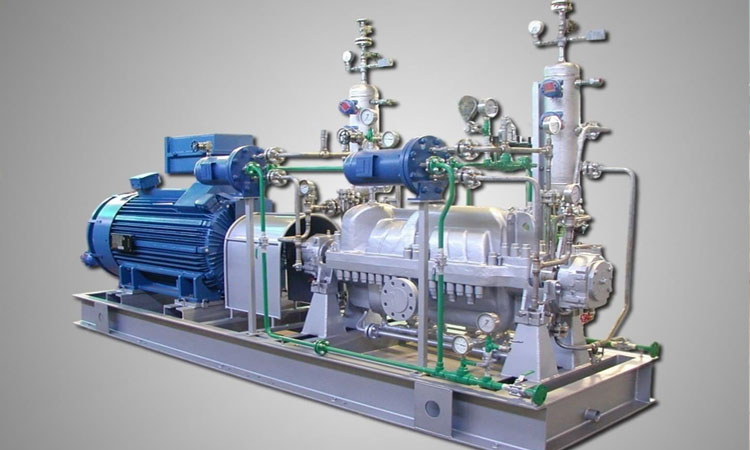

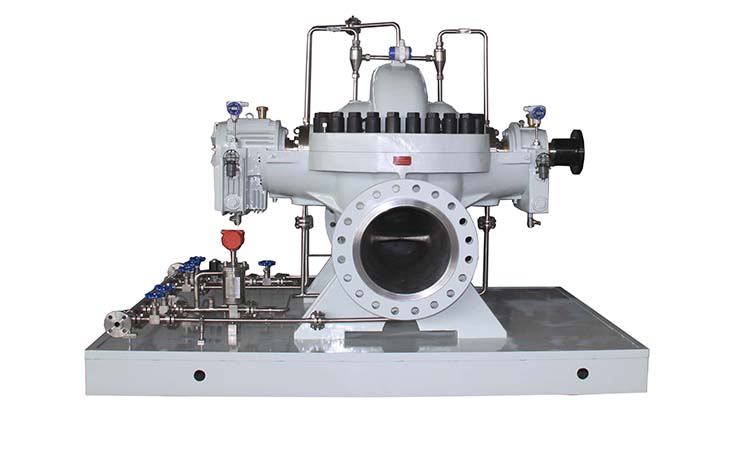

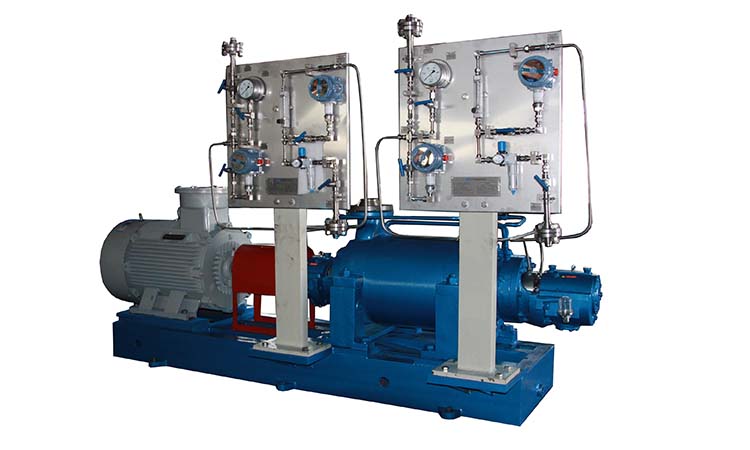

6. BB1-A Centrifugal Pump——KSY Series Oil Supply Pump

The BB1-A centrifugal pump is the BB1 pump in the API610 standard. It is an axially split, single-stage, horizontal, double-suction, end-supported pump. The BB1-A centrifugal pump is an ideal choice for the continuous operation service of petrochemical oil refineries and long-distance pipeline feed pumps.

7. BB1-A Centrifugal Pump——HPT Series Pipeline Oil Transmission Main Pump

This series of products are axially split, single-stage, horizontal, double-suction, two-end supported pumps. It is an ideal choice for continuous operation of main pumps in long-distance pipelines. It is suitable for oil refinery, petrochemical industry, petroleum pipeline transportation, boiler feed water, oilfield water injection, mine drainage, refined oil transportation and other chemical industries and other fields.

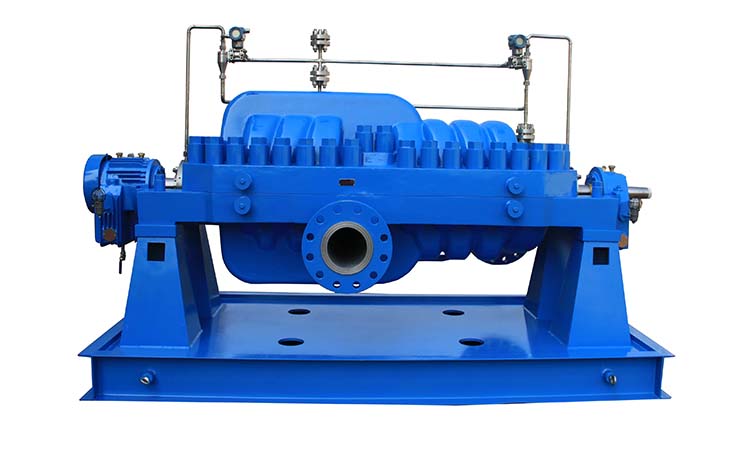

8. BB3 type centrifugal pump——KND type multistage pipeline oil delivery main pump

This series of products are axially split, multi-stage, horizontal, impeller-optional first-stage double-suction and both-end supported pumps. BB3 centrifugal pumps are mainly used in refineries, petrochemical industries, oil pipeline transportation, boiler water supply, oilfield water injection, mine drainage, refined oil transportation and other chemical industries.

9. BB4 type centrifugal pump——AY type multistage centrifugal oil pump

It is an updated product centered on energy saving. BB4 centrifugal pump is suitable for petroleum refining, petrochemical and chemical industries. It can also be used to transport petroleum, liquefied petroleum gas, etc. without solid particles. At the same time, the BB4 centrifugal pump is also suitable for low temperature, high temperature and corrosive media.

10. BB3 type centrifugal pump——KND type multistage pipeline oil delivery main pump

This series of products is an axially split, multi-stage, horizontal, impeller optional first-stage double-suction, two-end support pump. BB3 centrifugal pump has the advantages of energy saving, low carbon and environmental protection. It is suitable for oil refinery, petrochemical industry, petroleum pipeline transportation, boiler feed water, oilfield water injection, mine drainage, refined oil transportation and other chemical industries and other fields.

11. BB3 type centrifugal pump——KND type multistage pipeline oil delivery main pump

This series of products are axially split, multi-stage, horizontal, with optional first-stage double-suction impellers and two-end support pumps, which are energy-saving, low-carbon, and environmentally friendly. BB3 centrifugal pump is suitable for oil refinery, petrochemical industry, petroleum pipeline transportation, boiler water supply, oil field water injection, mine drainage, refined oil transportation and other chemical industries and other fields.

12. VS4 centrifugal pump - submerged pump

CYA submerged pump is a long shaft design. The medium is discharged laterally and has a separate outlet pipe. VS4 centrifugal pumps are mostly used for the discharge of liquids in open sewage pools or closed storage tanks.

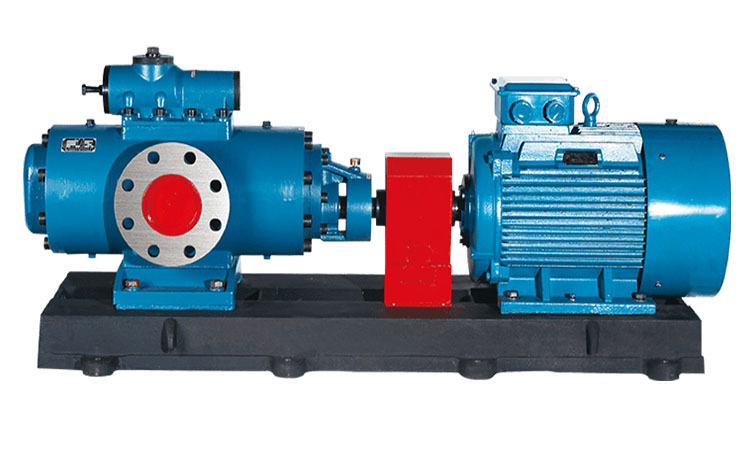

13. Cam pump——HC type heavy oil pump

This series of pumps is driven by NGW planetary reducer with mechanical seal and high efficiency. It has the characteristics of low speed, high efficiency, stable operation, strong self-priming ability, convenient operation, pump preheating, reliable performance and long service life.