Working principle and unique advantages of screw pump

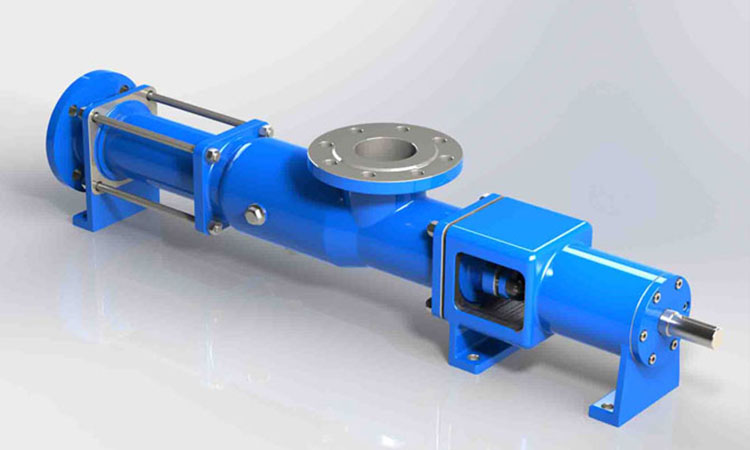

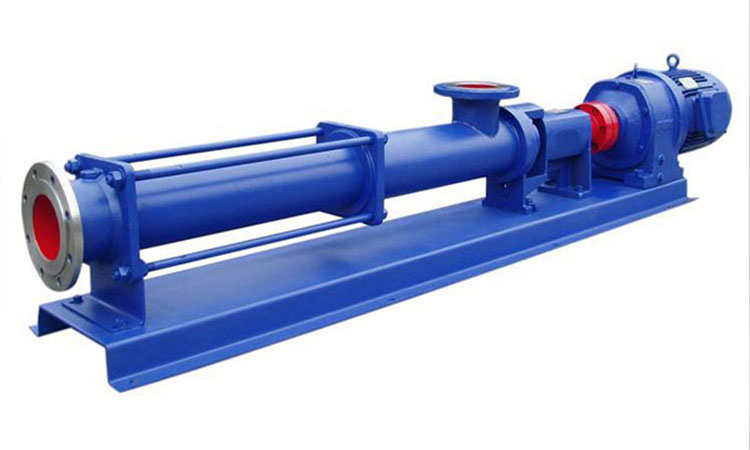

A screw pump is a type of positive displacement pump that uses rotating screws or helical rotors to move fluid from the inlet to the outlet. It consists of two or more intermeshing screws or rotors that rotate within a closely fitting casing.

The key principle behind a screw pump is the displacement of fluid. The rotating screws create a continuous flow of fluid by displacing the trapped fluid from the inlet to the outlet. This displacement produces relatively low pulsations and a smooth delivery of the fluid.

A screw pump is a type of positive displacement pump that operates using the principle of rotating screws or hel.

Working of screw pump

Screw Configuration: Screw pumps consist of two or more intermeshing screws or rotors that rotate within a closely fitting casing. The screws have a helical shape, resembling two mating screws, and are usually referred to as the male and female rotors.

Fluid Entrapment: As the rotors rotate, the fluid is trapped in the cavities between the rotor threads and the casing. The fluid is carried along the threads and transported from the inlet to the outlet as the rotors rotate.

Displacement and Flow: The trapped fluid is continuously displaced and pushed forward due to the intermeshing of the screw threads. This displacement creates a continuous flow of fluid with relatively low pulsations and smooth delivery.

Screw pumps are often used for pumping viscous fluids, as they can handle high-viscosity liquids more effectively than other pump types. They are also known for their self-priming capabilities, which means they can evacuate air from the suction pipe and draw in the fluid without external priming assistance. This feature is advantageous in applications where the pump needs to be located above the fluid level or when dealing with gaseous or volatile fluids.

Unique Advantages of screw pump

1.Self-Priming Capability: Screw pumps possess excellent self-priming capabilities, meaning they can evacuate air from the suction pipe and create a vacuum to draw in the fluid without the need for external priming assistance. This feature is advantageous in applications where the pump needs to be located above the fluid level or when dealing with gaseous or volatile fluids.

2.High Viscosity Handling: Screw pumps are well-suited for handling high-viscosity fluids and can effectively pump thick, heavy, or viscous liquids. The intermeshing screw design allows for better fluid transport, even with liquids that are difficult to pump using other pump types.

3.Minimal Shear and Low Pulsation: Screw pumps offer gentle fluid handling due to their low shear characteristics. They generate minimal turbulence and shear forces, making them suitable for transporting shear-sensitive fluids, such as certain chemicals, polymers, or food products. The low pulsation flow also reduces stress on the system and minimizes the chances of damage or disruption to the fluid being pumped.

4.Solid Handling Capability: Screw pumps can handle fluids containing solids or abrasive particles without significant issues. The large flow passages between the screw threads allow for the passage of small solid particles, preventing clogging and reducing the need for frequent maintenance or cleaning.

5.Reversible Operation: Screw pumps can operate in either direction, offering flexibility in system design and allowing for reversible flow if required. This feature can be advantageous in applications where bidirectional flow or quick changeovers are necessary.

6.Efficient and Reliable: Screw pumps are known for their high efficiency and reliable operation. They can deliver a consistent flow rate with minimal power requirements, resulting in energy savings. Additionally, their robust construction and simple design contribute to their durability and long service life.

Overall, screw pumps are versatile, reliable, and efficient devices that excel in handling high-viscosity fluids, self-priming applications, and situations where low shear and minimal pulsations are crucial.