Working Principles and Performance Features of Shale Shakers

Shale shakers play a crucial role in the drilling industry, particularly in the extraction of oil and gas from shale formations. Sino Mechanical is a leading manufacturer and supplier of high-performance and reliable shale shakers designed to efficiently separate drilling cuttings from drilling fluids. In this article, we will explore the working principles and performance features of Sino Mechanical's shale shakers.

Working Principles:

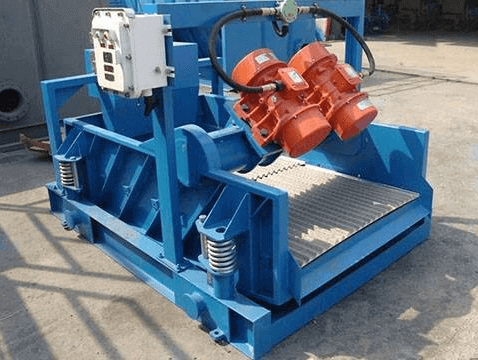

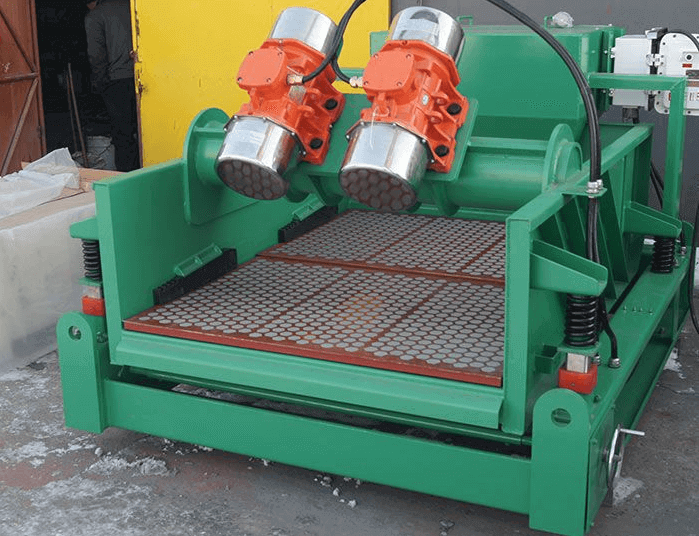

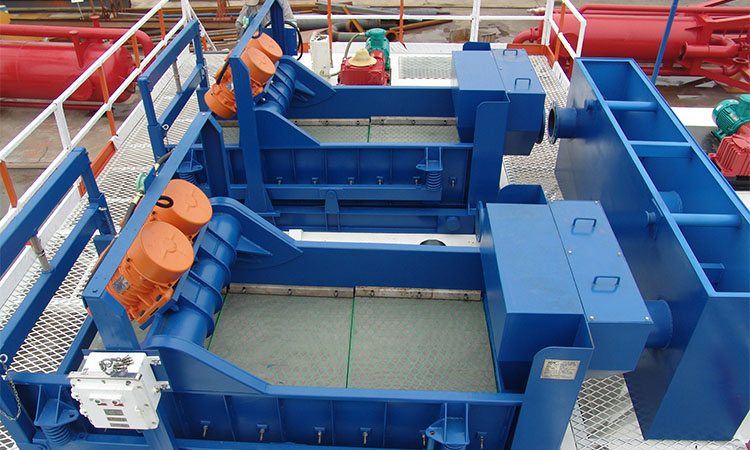

Shale shakers operate based on the principles of vibration and mechanical screening. The main components of a shale shaker include a vibrating screen, feed distribution system, and a collection pan. The working principles can be summarized as follows:

1. Feed Distribution: The drilling fluid containing the cuttings is fed onto the vibrating screen through the feed distribution system. The distribution system evenly spreads the fluid across the screen surface, ensuring effective separation.

2. Vibration: Once the fluid reaches the screen, the shale shaker initiates high-frequency vibrations. These vibrations cause the drilling cuttings to move rapidly along the screen surface.

3. Screening: As the cuttings move across the vibrating screen, the mesh openings of the screen allow the fluid to pass through while retaining the larger solids. This separation process effectively separates the drilling cuttings from the drilling fluid.

4. Collection: The separated drilling cuttings are collected on the screen surface and are then discharged into a collection pan. The clean drilling fluid, known as the "mud," passes through the mesh and is collected for further processing.

Performance Features:

Sino Mechanical's shale shakers are renowned for their high-performance capabilities and exceptional reliability. Here are some key performance features:

1. Efficient Solid Separation: The shale shakers employ advanced vibration technology and optimized screen configurations to achieve efficient solid separation. The high-frequency vibrations and precisely engineered screen mesh allow for effective removal of drilling cuttings from the drilling fluid.

2. Adjustable Screen Deck Angle: Sino Mechanical shale shakers offer the flexibility of adjusting the screen deck angle. This feature allows operators to optimize the separation efficiency based on the specific drilling conditions and types of cuttings encountered.

3. Enhanced Screen Life: The shale shakers incorporate durable and high-quality screens that are designed to withstand the demanding drilling environment. Sino Mechanical employs innovative screen manufacturing techniques and materials to ensure extended screen life and reduced downtime for screen replacements.

4. Easy Maintenance: Sino Mechanical's shale shakers are designed with ease of maintenance in mind. The user-friendly design and accessible components facilitate quick and hassle-free maintenance, minimizing downtime and maximizing operational efficiency.

5. Compact and Space-Saving Design: Sino Mechanical shale shakers feature a compact and space-saving design, making them suitable for various drilling rig setups. The compact footprint ensures efficient utilization of available space on drilling sites.

Sino Mechanical's shale shakers offer efficient and reliable solid separation solutions for drilling applications. Their working principles based on vibration and mechanical screening enable effective separation of drilling cuttings from drilling fluids. With high-performance capabilities, adjustable screen deck angles, enhanced screen life, easy maintenance, and a compact design, Sino Mechanical shale shakers are trusted by the drilling industry to deliver optimal performance and productivity.