Working Principle of Ram Blowout Preventer(BOP)

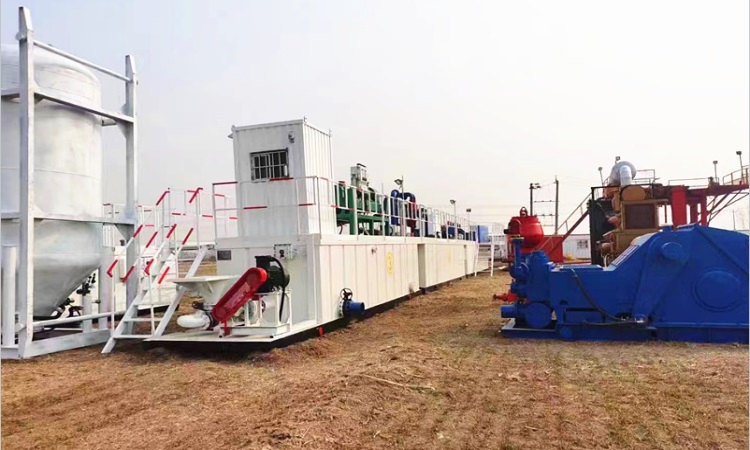

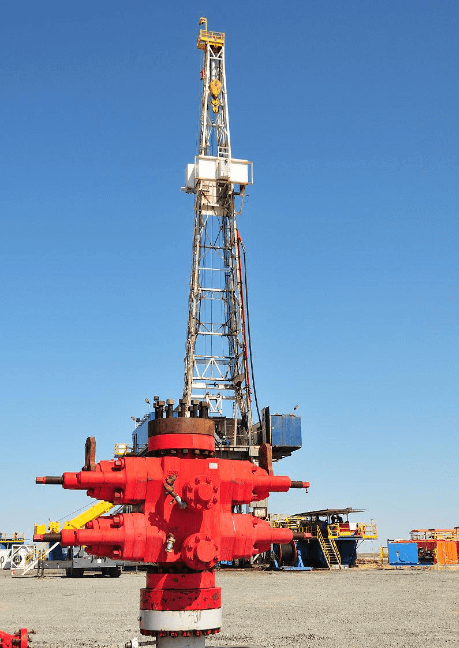

The Ram Blowout Preventer (BOP) is an essential safety device used in the oil and gas industry to prevent uncontrolled releases of oil or gas from a well during drilling, completion, or intervention operations. The BOP is typically installed on the wellhead and consists of various components, including ram assemblies.

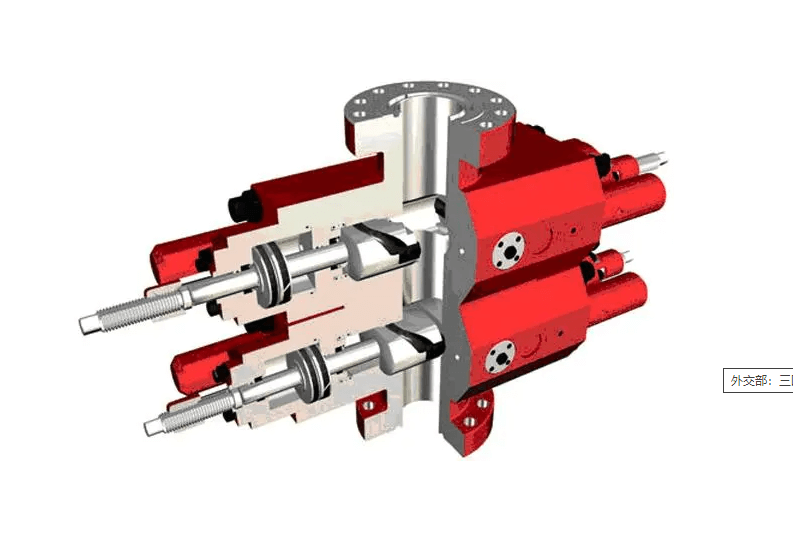

The working principle of a Ram BOP involves the use of two or more sets of hydraulically operated rams that can seal off the wellbore, effectively closing it and preventing the flow of fluids. Each ram assembly consists of two steel blocks called rams that are designed to fit together and form a seal.

Here's a step-by-step overview of how a Ram BOP operates:

Activation: When a well control situation arises, the Ram BOP is activated by hydraulic pressure. This pressure is typically supplied by an accumulator system that stores hydraulic energy.

Closing: The hydraulic pressure is directed to the Ram BOP, causing the rams to close. The rams are moved towards the centerline of the wellbore, where they meet and form a seal. There are different types of rams, such as pipe rams, blind rams, or shear rams, each designed for specific functions.

Sealing: Once the rams are closed, they create a tight seal around the tubulars in the well, such as drill pipe, casing, or tubing. This prevents the uncontrolled release of fluids.

Pressure control: With the rams closed, pressure control equipment, such as a choke manifold or a kill line, can be employed to control the wellbore pressure and safely divert or contain the flow of fluids.

Release: After the well control situation is resolved, the hydraulic pressure is released, and the rams open to allow the resumption of normal drilling or production operations.

Overall, a ram blowout preventer controls the injection speed and pressure of the fluid by converting and consuming the kinetic energy generated when closing the valve, thereby protecting the safety of the pipeline system and operators. They are widely used in many industrial applications, especially in liquid or gas transmission pipelines, to reduce the risk of spray accidents.

The Ram BOP is designed to withstand high pressures and temperatures encountered in oil and gas wells. It serves as a vital barrier against blowouts, which can have severe environmental, safety, and economic consequences. Regular maintenance, testing, and adherence to industry standards are crucial to ensure the proper functioning of Ram BOPs and overall well control safety.