What is the difference between drill pipe and drill collar?

A drill pipe and a drill collar are both components used in drilling operations in the oil and gas industry. While they are both part of the drill string, they serve different purposes and have distinct characteristics. Here are the main differences between drill pipes and drill collars:

Function:

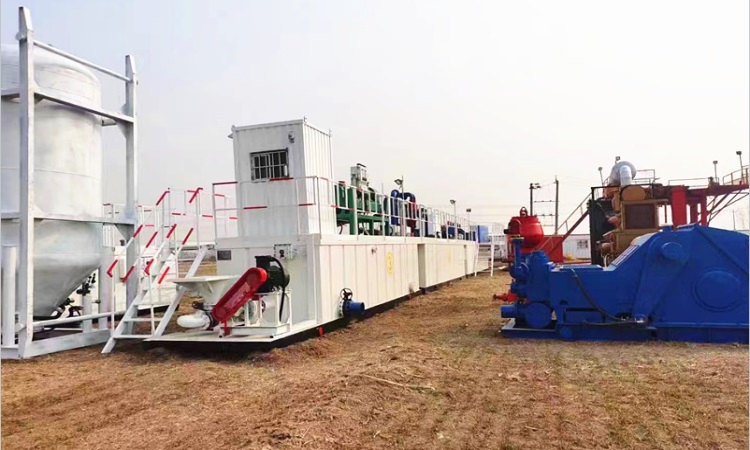

Drill Pipe: Drill pipes are long, hollow steel tubes that connect the drilling rig's surface equipment to the drilling bit. They provide a conduit for drilling fluid (mud) to circulate down the pipe and back up to the surface, carrying cuttings and providing hydraulic pressure to the bit.

Drill Collar: Drill collars are heavy, thick-walled steel tubes placed near the bottom of the drill string, just above the drill bit. They provide weight to the bit, maintaining the desired level of force for efficient drilling. Drill collars are primarily used for downward force, while drill pipes are more focused on fluid circulation.

Construction:

Drill Pipe: Drill pipes are made from seamless or welded steel tubes. They consist of three main sections: the tube body, tool joints at each end, and a mid-body that connects them. The tool joints are thicker and stronger to handle the stress and torque during drilling operations.

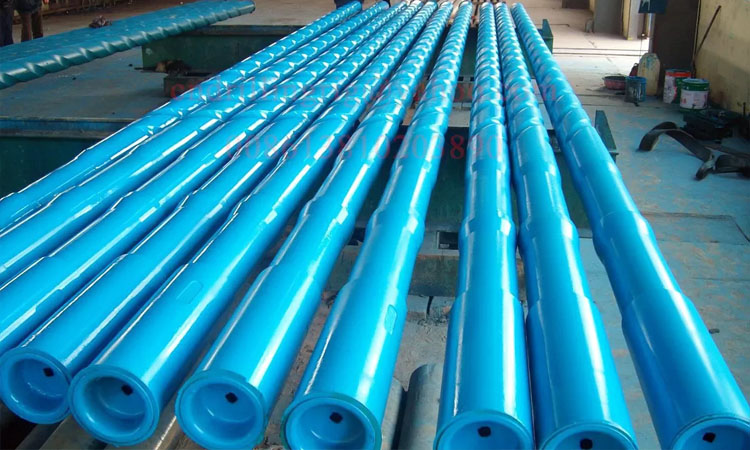

Drill Collar: Drill collars are solid, non-magnetic bars made from a single piece of alloy steel. They have a larger outer diameter (OD) compared to drill pipes, providing the necessary weight for the drill bit. Drill collars are typically heavier and shorter than drill pipes.

Weight and Strength:

Drill Pipe: Drill pipes are relatively lighter and less rigid than drill collars since their primary function is to transfer drilling fluid. They are designed to withstand bending stresses and internal pressure but are not primarily intended for applying weight to the bit.

Drill Collar: Drill collars are significantly heavier and stronger than drill pipes. Their added weight helps maintain the required pressure on the drill bit for efficient drilling. Drill collars are built to handle the high axial loads and torque encountered during drilling.

Placement in the Drill String:

Drill Pipe: Drill pipes are connected in a series to form the majority of the drill string. Multiple sections of drill pipes are joined together with threaded connections to achieve the necessary length to reach the desired drilling depth.

Drill Collar: Drill collars are placed close to the bottom of the drill string, typically above the drill bit. They are connected to the bottommost drill pipe through a threaded connection. The number of drill collars used can vary depending on the drilling requirements.

In summary, while both drill pipes and drill collars are integral components of the drill string, their primary functions and designs differ. Drill pipes are lighter, hollow tubes used to circulate drilling fluid, while drill collars are solid, heavy bars that provide weight and stability to the drill bit.