What is the Difference between a Mud Separator and a Mud Decanter Centrifuge?

In the field of industrial processes, particularly in sectors such as oil and gas, wastewater treatment, and solid waste management, the effective separation and treatment of mud are of utmost importance. Two commonly used equipment for this purpose are mud separators and mud decanter centrifuges. While both serve the purpose of separating solids from liquids, there are notable differences between these two technologies. This article aims to shed light on the dissimilarities between a mud separator and a mud decanter centrifuge.

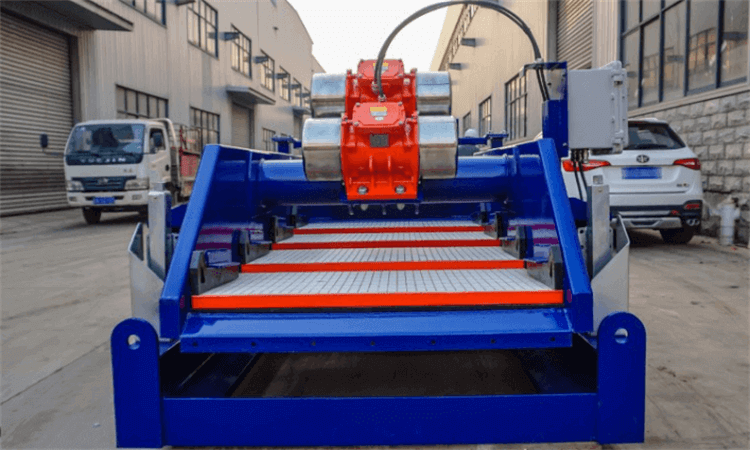

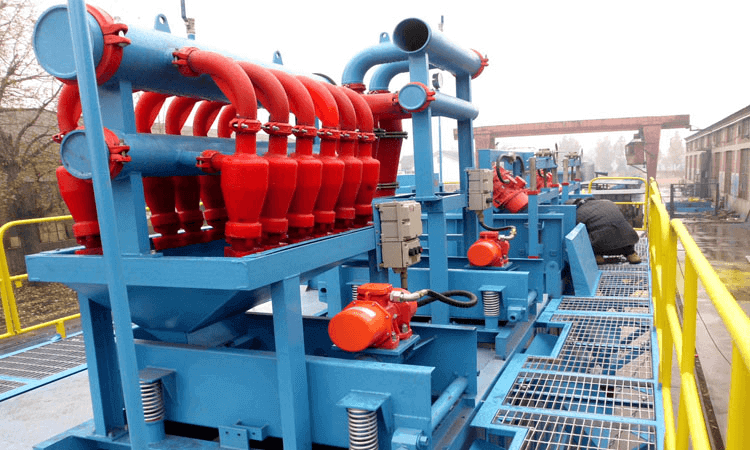

Mud Separator:

A mud separator, also known as a mud cleaner or desander, is primarily designed to remove larger-sized particles from mud or drilling fluids. It operates on the principle of gravity settling and cyclonic separation. The mud is passed through a set of hydrocyclones, which create centrifugal force. As a result, the heavier solids settle down to the bottom, while the cleaner fluid rises to the top and is discharged. Mud separators are effective in removing particles with a size range of 40 to 100 microns. They are generally employed as a primary separation step in the mud treatment process.

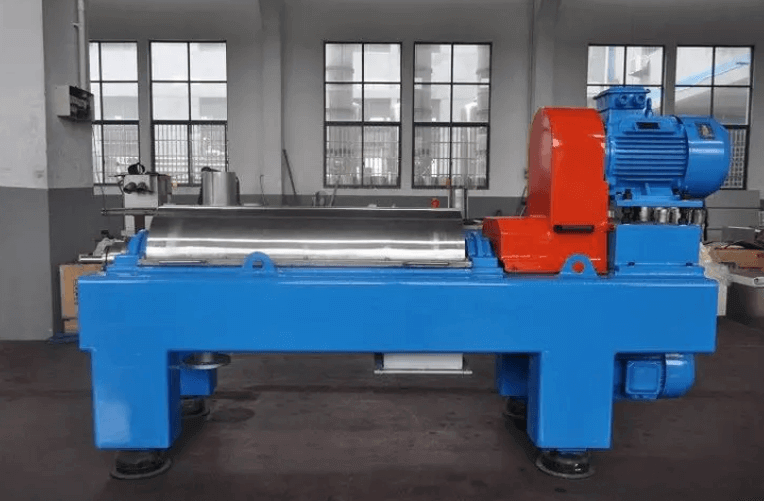

Mud Decanter Centrifuge:

On the other hand, a mud decanter centrifuge is a more advanced and versatile equipment used for finer solids separation. It utilizes the principles of centrifugal force and differential sedimentation to achieve efficient separation. Mud decanter centrifuges can handle a wide range of particle sizes, typically in the range of 2 to 50 microns. The equipment consists of a rotating bowl and a screw conveyor inside it. The centrifugal force generated by the high-speed rotation of the bowl forces the solids to settle on the inner walls, while the liquid phase is expelled through the discharge ports. The screw conveyor continuously transports the solids towards the conical end for further dewatering and discharge.

Distinguishing Factors:

Particle Size Range: Mud separators are primarily effective in removing larger particles (40-100 microns), while mud decanter centrifuges can handle finer solids (2-50 microns).

Separation Mechanism: Mud separators rely on gravity settling and cyclonic separation, whereas mud decanter centrifuges utilize centrifugal force and differential sedimentation for separation.

Application and Efficiency: Mud separators are commonly used as a preliminary step to remove coarse solids, while mud decanter centrifuges are employed for a more thorough separation, achieving a higher level of solids removal and liquid clarity.

Equipment Design: Mud separators typically consist of hydrocyclones, while mud decanter centrifuges have a rotating bowl with a screw conveyor.

In summary, mud separators and mud decanter centrifuges are two distinct technologies used for mud separation in various industries. Mud separators are effective in removing larger particles and are often used as a primary separation step. On the other hand, mud decanter centrifuges offer a more advanced and efficient solution, capable of handling a wider range of particle sizes. Understanding the differences between these two equipment types is crucial for selecting the appropriate technology based on the specific requirements of the application at hand.