What is drilling drawworks

Principle and structure of drilling drawworks

The drawworks is an important equipment of the hoisting system and the core equipment of a drilling rig.

The working principle of the drilling drawworks mainly relies on the combined operation of the motor, reducer, transmission shaft, wire rope and pulley. The specific working process is as follows: the electric motor provides power and transmits the power to the reducer through the transmission shaft. The reducer reduces the speed of the motor and increases the torque so that the speed drops to an appropriate value.

The reducer then drives the pulley to rotate, and the pulley transmits power to the drill pipe and drill bit through the wire rope. In the lifting and rotating motion of the drawworks, the brake and transmission device play a key role, which can control the movement speed of the drawworks and ensure the accuracy and safety of the operation. The lifting speed and rotation speed of the drawworks can be achieved by controlling the transmission mechanism. In addition, the control system of the drilling drawworks can adjust the sliding speed, while ensuring the correct implementation of the lifting operation and braking of the drum, ensuring the stable and safe operation of the equipment.

The function of drawworks

1. During the drilling process, the drilling tools are suspended, the drill string and drill bit are fed, and the drilling pressure is controlled.

2. Tripping drilling tools and casing during tripping operations.

3. Use the cat head mechanism of the drawworks to tighten and remove drilling tool threads and lift heavy objects.

4. As the speed change mechanism and intermediate transmission mechanism of the turntable.

5. For jack-up derrick drilling rigs, it is used to raise and lower the derrick

6. Use the sand drum of the drawworks to extract cores, test oil, etc.

Classification of drawworkses

There are many types of drilling drawworks, but the number of drawworks central shafts that best reflects its structural characteristics is the number of drawworks shafts. The following is a simple summary and analysis of various drawworks based on the number of drawworks shafts.

1. Single and double-shaft drawworks: The original drawworks of the drilling rig was a single-shaft drawworks. This drawworks had only one drum shaft. The speed change of the drawworks was realized by an independent four-speed-reverse gearbox in front of the drawworks. This kind of drawworks The characteristics of the cat head are that the rotation speed of the cat head is too high, the position is too low, and the operation is inconvenient. In order to overcome the shortcomings of the single-shaft drawworks, a double-shaft drawworks was developed. Because it is assembled on one shaft alone, it becomes a double-shaft drawworks. Single and double-shaft drawworkses are generally suitable for shallow wells or medium-deep wells.

2.Three-axis and multi-axis drawworkses

In order to meet the needs of deep well and ultra-deep well drilling, three-axis and multi-axis drawworks have come out one after another. Drawworks with more than four axes are multi-axis drawworks. Contemporary heavy-duty and super-heavy-duty drawworks belong to this type of drawworks.

3. Independent cat head shaft-multi-axis drawworks

Because heavy-duty and super-heavy-duty drawworks have large dimensions and weight (generally 20~30t), and are difficult to transport and install, especially contemporary deep well and ultra-deep well drilling rigs with higher drill floors (usually 6~11m). In order to prevent the drawworks from raising the drill floor unnaturally Lifting derrick, and in recent years, an independent cat head shaft-multi-axis drawworks has been developed. The structural plan of this type of drawworks is: ① The independent cat head shaft and the turntable transmission device form a unit, which is placed on the drill floor and is responsible for connecting and unloading drill threads and lifting general heavy objects. It can also serve as the intermediate transmission device of the turntable. ② The main drawworks is placed on the backstage or on the linkage base below the drill floor, and is responsible for lifting tasks such as running drilling tools, running casing, handling accidents, etc., and can avoid long drilling floor chains. The drum, cathead mechanism and turntable of this kind of drawworks all have their own gear speeds and braking mechanisms, so that they can achieve better working characteristics according to needs.

4. Electric drived rawworks: Due to the advent of DC drive and AC variable frequency electric drive drilling rigs, electric drive drawworkses with a simpler structure have emerged. This type of drawworks uses a DC motor or an AC variable frequency motor as power to drive the drum shaft and cat head shaft respectively. Because the structure of the electric drawworks is relatively simple, the cat head shaft generally does not have a separate unit and is integrated with the main drawworks.

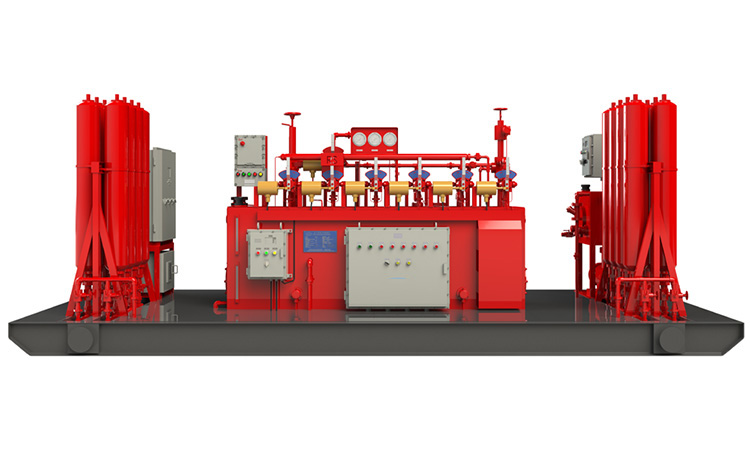

Sino Mechanical provides various oil drilling equipment, such as: drawworks,air winches, blowout preventers , accumulator Unit/BOP control system, and accessories,etc. We are based in Shengli Oilfield, the second largest oil field in China, and provide reliable drilling equipment and services to the world.