What are the Different Types of Drilling Stabilizers

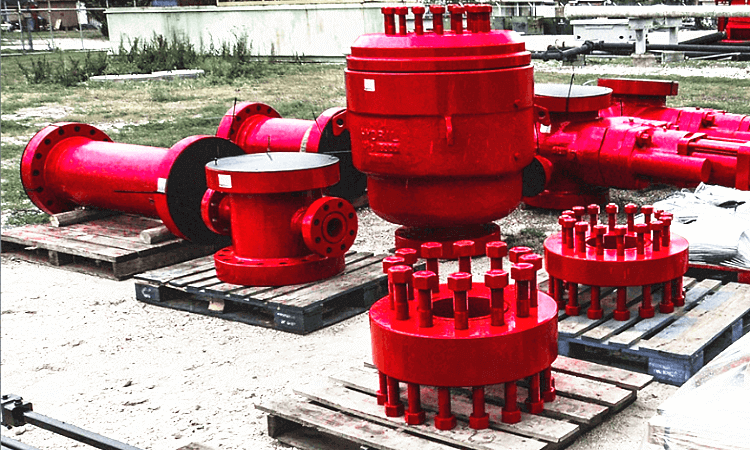

In drilling operations, stabilizers are important tools used to maintain the stability and direction of the drill bit during the drilling process. They help prevent deviation and ensure smooth drilling operations. There are several types of stabilizers commonly used in drilling, including:

Blade Stabilizers: Blade stabilizers feature flat or curved blades attached to the drill collar. They provide radial support to the drill string and help maintain its central position. Blade stabilizers are effective in controlling hole deviation and minimizing vibrations.

Integral Blade Stabilizers (IBS): IBS are stabilizers with blades that are machined from a single piece of alloy steel. They are stronger and more durable compared to welded blade stabilizers. Integral blade stabilizers provide efficient weight distribution and enhanced stabilization.

Sleeve Stabilizers: Sleeve stabilizers consist of a series of cylindrical sleeves that encircle the drill collar. These sleeves can be rotated to adjust the stabilizer diameter, allowing for customization based on the drilling conditions. Sleeve stabilizers offer flexibility and are suitable for various wellbore sizes.

Non-Rotating Stabilizers (NR Stabilizers): Non-rotating stabilizers are designed to prevent the rotation of the drill string while the drill bit is rotating. They typically feature a sleeve with a spiral groove that matches the drill string's pitch. This prevents the stabilizer from rotating, ensuring it remains stationary while the drill bit operates.

Replaceable Blade Stabilizers (RBS): RBS consists of a stabilizer body with replaceable blades. This design allows for easy blade replacement when worn or damaged, reducing downtime and costs. Replaceable blade stabilizers offer versatility and cost-effectiveness.

Adjustable Stabilizers: Adjustable stabilizers have movable blades that can be retracted or extended, allowing for on-site adjustments to match the drilling conditions. This type of stabilizer provides adaptability and flexibility during drilling operations.

The selection of stabilizers depends on various factors such as wellbore conditions, drilling objectives, and equipment specifications. Drillers and drilling engineers consider these factors to choose the most suitable stabilizer type and configuration for optimal drilling performance and stability.