What are choke manifold and kill manifold ?

Choke manifold and kill manifold

Choke manifold and kill manifold are important components of oil and gas well pressure control equipment, and they play a key role in oil and gas well operations.

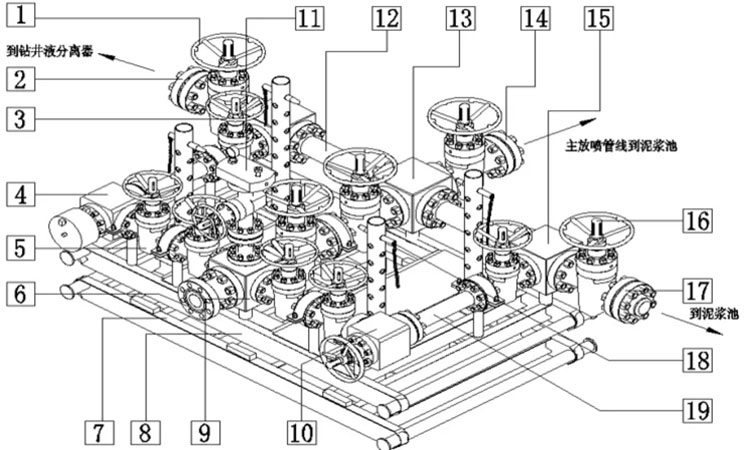

Choke manifold

The choke manifold is a necessary equipment for controlling well kicks and implementing oil and gas well pressure control technology. The choke manifold is a tool for controlling wellhead flow, usually used to reduce the invasion of drilling fluid on the formation during drilling. It consists of a choke and a connecting pipe. The aperture of the choke can usually be adjusted as needed to maintain the stability of the wellhead flow.

During the drilling process, the choke manifold can control the flow at the wellhead and control the flow state of the drilling fluid in the well. Its main function is to control the flow at the wellhead to prevent the formation from being invaded by the drilling fluid, and it can also control the pressure in the well to ensure the safety of the operation.

The main functions of the choke manifold include:

1. Control well kick: When the blowout preventer is closed, the choke valve is opened and closed to control a certain casing pressure, maintain the bottom hole pressure slightly greater than the formation pressure, prevent the formation fluid from further flowing into the well, and stop overflow.

2. Implement well killing operations: Through the throttling effect of the throttle valve, replace the contaminated drilling fluid in the well and control the wellhead pressure.

3. Soft well shut-in: During overflow, the throttle valve is used to reduce the wellhead pressure and achieve "soft well shut-in" to prevent the water hammer effect from acting on the wellhead and protect the safety of equipment and personnel.

4. Safety: Through the large amount of discharge of the blowout valve, the overflow is led out of the well site to prevent fire and poisoning of personnel in the well site and ensure drilling safety.

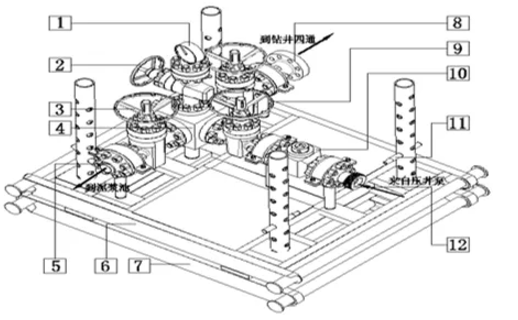

Kill manifold

Kill manifold is an important component of oil and gas well pressure control equipment. Kill manifold is usually used to control the pressure at the wellhead, especially when the wellhead is out of control. It consists of a set of connecting pipes, which can adjust the flow of inlet and outlet to achieve the purpose of controlling the wellhead pressure.

During the drilling process, the kill manifold can be controlled when the wellhead is out of control to achieve the purpose of controlling the wellhead pressure. Its main function is to control the wellhead pressure and ensure the efficient drilling process. If the wellhead pressure is too high, the kill manifold can be used to reduce the wellhead pressure, thereby eliminating the safety hazards of the drilling wellhead.

The main functions of the kill manifold include:

1. Pumping drilling fluid: When it cannot circulate normally through the drill string, the drilling fluid is pumped into the well through the kill manifold to achieve the purpose of controlling the well pressure.

2. Handling special situations: In the event of a blowout, clean water or fire extinguishing agent is injected through the kill manifold to prevent the accident from expanding.

Installation location and usage scenarios

1. Choke manifold: Usually installed on the right wing of the wellhead spool to control the outflow and pressure relief of the fluid in the well.

2. Kill manifold: Installed on the left wing, used for well killing operations and special situation handling.

Technical parameters and structural composition

1. Choke manifold: The working pressure range is 3000PSI to 15000PSI, and the working media include natural gas, mud, etc. The main components include choke valves, gate valves, pipelines and pressure gauges, choke manifold control boxes, etc.

2. Kill manifold: Usually connected to the side hole of the drilling spool, one end is connected to the drilling mud pump, and the main components include check valves, gate valves and pressure gauges, etc., which are used to pump drilling fluid to control the well pressure.

Practical application scenarios and importance

In oil and gas well operations, choke manifold and kill manifold are key equipment to ensure the safety and smooth progress of operations. They can effectively control the pressure in the well, prevent accidents such as well kicks and blowouts, and protect the safety of drilling equipment and personnel.

Sino Mechanical Equipment supplies choke manifolds, well-killing manifolds, and various types of choke hoses and killing hoses, choke valves, flat gate valves, pipe fittings, etc.