Wellhead Blowout Preventers and Measures for Blowout Prevention in Drilling Operations

Wellhead blowouts during drilling operations are serious accidents that can result in casualties and equipment damage. To ensure the safety of drilling operations, it is crucial to employ appropriate blowout preventers and measures. This article will introduce common wellhead blowout preventers used in drilling processes and discuss preventive measures to mitigate blowouts.

Wellhead blowout preventers are essential equipment in drilling operations to prevent blowout accidents. This article will provide an overview of common wellhead blowout preventers employed during drilling and explore measures to prevent blowouts.

Common Wellhead Blowout Preventers:

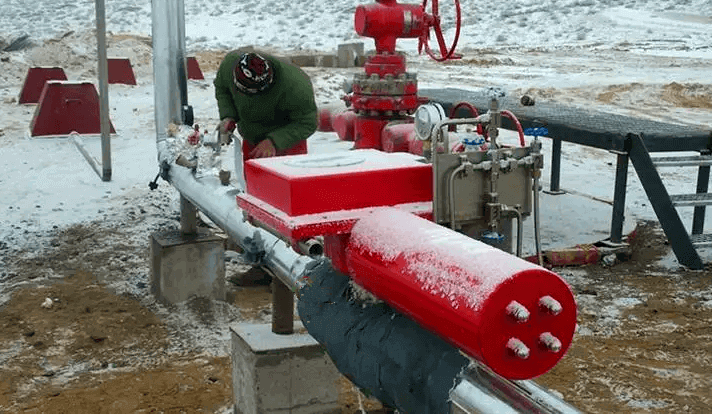

Surface Safety Valve (SSV): The surface safety valve is a critical blowout preventer installed on the wellhead valve. It is designed to rapidly close the wellhead, cutting off the fluid flow and preventing blowouts. The SSV possesses fast closure and reliable sealing capabilities, making it an indispensable device in drilling operations.

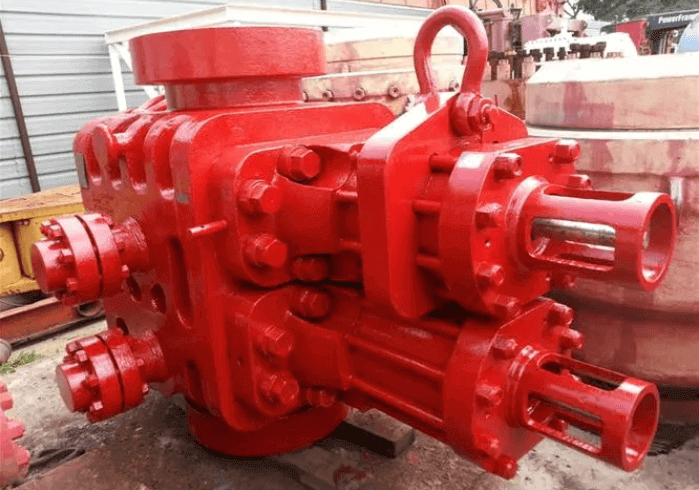

Blowout Preventer (BOP) Stack: The blowout preventer stack is a set of stacked blowout preventers located above the drill string. It consists of blowout preventer stacks and valves, which are utilized to control blowouts and protect drilling equipment. The BOP stack incorporates multiple layers of seals and valve systems to effectively prevent the escape of drilling fluid or gas from the wellhead.

Drill Pipe Safety Valve (DPSV): The drill pipe safety valve is a blowout preventer mounted on the drill pipe. It is designed to shut off the fluid passage above the drill pipe when blowouts occur. The DPSV promptly closes to prevent the flow of drilling fluid out of the drill pipe, safeguarding the personnel and equipment.

Measures for Blowout Prevention:

Safety Design and Planning: Comprehensive engineering design and risk assessment should be conducted prior to drilling operations. This includes thorough examination of geological and formation conditions, and the development of appropriate safety plans. Ensuring that well design and construction meet relevant safety standards and regulations is vital.

Well Pressure Control: Regular well pressure testing should be performed to ensure that the wellbore pressure remains within the safe range. Monitoring pressure changes closely during drilling operations and adjusting the density and properties of drilling fluid accordingly helps control bottom hole pressure and prevent wellbore collapse.

Appropriate Drilling Fluid: Selecting suitable drilling fluid provides sufficient buoyancy and bottom hole stability, preventing wellbore collapse and blowouts. Monitoring the composition, density, and circulation of the drilling fluid ensures compliance with requirements.

Proper Installation and Operation of Wellhead Safety Valves: Wellhead safety valves should be installed and operated correctly to ensure rapid closure during blowouts, effectively stopping the flow of fluids and minimizing injuries and losses caused by blowouts.

Training and Drills: Training drilling personnel to understand the hazards of blowouts, emergency response procedures, and operational skills is crucial. Regular simulation drills and emergency exercises improve the capability and response time to handle blowout incidents.

Wellhead blowout preventers play a critical role in drilling operations. By appropriately deploying and operating these devices, along with implementing preventive measures, the risk of blowout accidents can be significantly reduced, ensuring the safety and efficiency of drilling operations. Emphasizing training and raising awareness among all drilling personnel regarding safety regulations and operational practices is essential to ensure the safe execution of the entire drilling process.