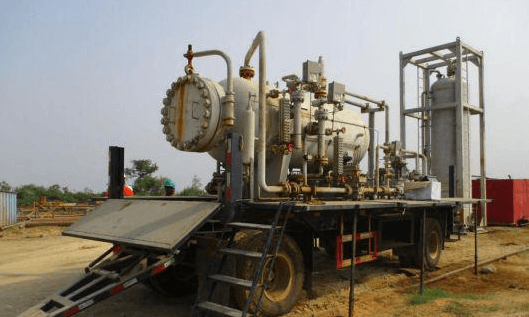

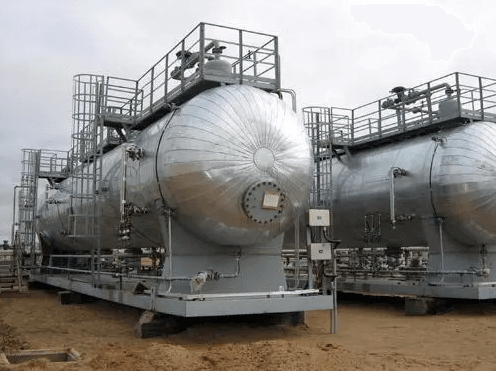

Types and Function of Oil Gas Separators

Oil and gas separators are essential equipment used in the petroleum industry to separate oil, gas, and water mixtures produced from oil wells. These separators employ various mechanisms and designs to efficiently separate the different components based on their densities. Here are the main types of oil and gas separators and their functions:

Horizontal Separator:

Function: The most common type of separator used in the oil and gas industry. It separates oil, gas, and water based on their density differences.

Mechanism: The fluid mixture enters the separator tangentially, creating a centrifugal force that separates the gas from the liquid. The liquid phase settles at the bottom, while the gas phase exits from the top.

Vertical Separator:

Function: Similar to a horizontal separator, a vertical separator separates oil, gas, and water based on their density differences.

Mechanism: The fluid mixture enters the separator from the top, and gravity helps in separating the different components. The gas phase rises to the top, while the liquid phase settles at the bottom.

Three-Phase Separator:

Function: Used when there is a need to separate oil, gas, and water simultaneously.

Mechanism: The fluid mixture enters the separator, and the gas phase rises to the top. The liquid phase separates into oil and water, with the oil phase floating on top of the water phase.

Two-Phase Separator:

Function: Used to separate gas from the liquid phase (oil or water).

Mechanism: The fluid mixture enters the separator, and the gas phase rises to the top, leaving the liquid phase at the bottom.

Free Water Knockout (FWKO):

Function: Primarily used to separate water from oil and gas.

Mechanism: The fluid mixture enters the separator, and the water phase settles at the bottom, while the oil and gas phases rise to the top.

Filter Separator:

Function: Removes solid particles, impurities, and contaminants from oil and gas streams.

Mechanism: The fluid mixture passes through a filter medium, which traps solid particles and allows the clean oil or gas to pass through.

The specific type of separator used depends on the composition of the fluid mixture, flow rates, operating conditions, and other factors. These separators play a crucial role in optimizing the production process and ensuring the efficient separation of oil, gas, and water for further processing and transportation.