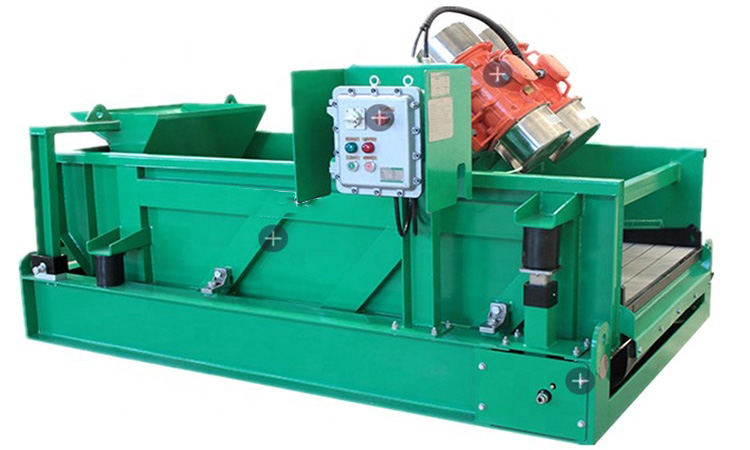

The screening principle of the drilling fluid Shale Shakers of solid control equipment

Drilling fluid Shale Shakers are important and necessary equipment in the drilling fluid solid control system, and their role is very important. What is the screening principle of drilling fluid Shale Shakers? How is it screened? During the drilling process, when the drilling fluid returns to the wellhead through the cuttings carried by the circulation system, flows into the Shale Shakers through the elevated trough, and is diverted to the Shale Shakers screen through the diversion box and the drilling fluid Shale Shakers logging tank, the solid and liquid begin to separate. However, solid-liquid separation is a process. When the drilling fluid first flows to the Shale Shakers screen, it is impossible to separate all of it immediately. Instead, while a small part is screened, most of the liquid phase is immediately separated along the surface of the screen, and a mud layer is formed on the surface of the screen. The mud layer becomes thinner and thinner as the separation proceeds until a certain position. The point where the liquid phase ends is generally called the liquid phase termination line. After passing the termination line, the solid phase particles continue to move forward until they leave the Shale Shakers. When the drilling fluid Shale Shakers work normally, the liquid phase termination line is generally located at about 2/3 to 3/4 of the effective length of the screen.

What is the screening principle of the drilling fluid Shale Shakers of solid control equipment?

The basic requirement of drilling technology for drilling fluid Shale Shakers is to remove as much harmful solid phase as possible and to recover as much drilling fluid as possible. The screening process includes the screening of the liquid phase and the movement of the solid phase on the screen. The solid phase is a rock cutting or a rock cutting group with irregular shapes and sizes, while the drilling fluid is a fluid with specific properties. The solid phase particles are immersed in the drilling fluid, and after separation, they are still wet particles surrounded by the drilling fluid. Therefore, the structure and parameters of the Shale Shakers and the screen, and the performance of the drilling fluid will directly affect the screening process.

In order to ensure the normal solid-liquid separation on the screen, whether the solid phase particles are immersed in the drilling fluid or have been separated, a certain forward movement speed is required. When the solid phase particles are in a submerged state, the migration speed is too slow and it is easy to block the screen, which reduces the processing volume and even causes the loss of cytoplasm and drilling fluid. After the solid and liquid are separated, if the migration speed is too slow, the probability of small particles passing through the screen will increase, and even solid particles will accumulate on the screen, causing the screen to be damaged prematurely due to excessive load.

Solid particles have the following movement forms on the screen surface:

Relative stillness: particles and particle clusters remain in contact with the screen and move with the screen surface.

Forward sliding: particles and particle clusters remain in contact with the screen and move relative to the screen surface toward the discharge outlet. Reverse sliding: particles and particle clusters remain in contact with the screen and move relative to the screen surface toward the discharge outlet.

Throwing angle: particles and particle clusters are thrown off the screen surface and move parabolically toward the discharge outlet.

In order to make the drilling fluid Shale Shakers have both a large processing capacity and a high chip removal speed, the particles should be thrown on the screen surface. During the throwing process, the particles are transported to the discharge outlet in a projectile shape, and the contact time and number of times with the screen are short, which greatly reduces the probability of small particles passing through the screen. However, it should be noted that the acceleration of the screen surface should not be too large, as long as the solid particles can overcome the adhesion between them and the drilling fluid and separate. Excessive normal acceleration will increase the collision of particles with the screen when they fall, resulting in a higher probability of small particles passing through the screen. Excessive normal acceleration also places higher requirements on the strength of Shale Shakers.

Supplier of drilling fluid Shale Shakers

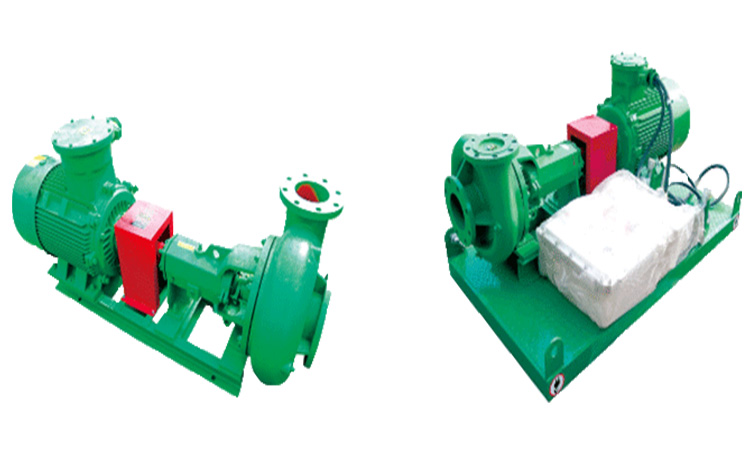

Sino Mechanical produces drilling fluid Shale Shakers in various models and specifications, and provides various types of Solids Control Systems, such as: Mud Cleaner, Decanter Centrifuge, Desanders andmud cleaner, Vacuum Degassers, Sand Pump, Mud Gas Separators, Mixing Hoppers, etc. Sino Mechanical Equipment is based on Shengli Oilfield, China's second largest oilfield, and provides high-quality oil equipment and services to the world. Sino Mechanical Equipment will continue to be committed to the research and development and provision of high-quality solids control equipment to meet the changing needs of customers.