The composition and characteristics of drilling drawworks

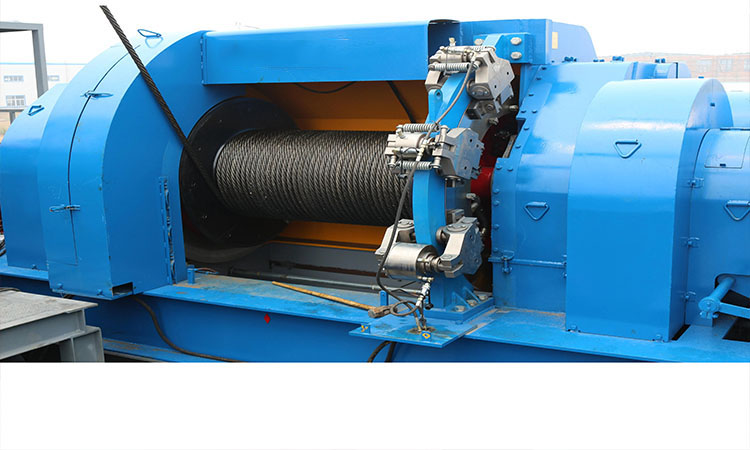

Drilling drawworks structure

The drilling drawworks is mainly composed of a drum shaft, a gear reduction box, a turntable transmission box, a drawworks frame, and lubrication, air control, and water cooling systems. The transmission mode is that the motor directly drives the drum shaft through the gear reduction box. The drilling floor is equipped with a hydraulic cat head to meet the requirements of drilling and tripping operations. The main brake of the drawworks is a hydraulic disc brake, and two brake discs are centrally arranged at the left end of the shaft. The auxiliary brake can be used for either energy consumption braking or Eaton disc air brake. The turntable is driven by an independent drive motor through a chain drive box, a bevel gearbox and a universal drive shaft. The independent drive motor is placed on the drill floor and is connected to the drawworks motor through the Eaton clutch on the right side. In this way, the two motors can be driven in parallel to drive the drawworks, can also be used interchangeably when one motor fails to improve the reliability of the drawworks and turntable.

Main components of drilling drawworks

1.Roller shaft assembly

The drum shaft assembly is mainly composed of a water-gas hoist, two brake discs, a drum body, a shaft and a bearing. There are cooling water channels, inlets, drains and drains in the brake disc. The grooved drum body is cast and welded in three sections.

2. Drawworks gear reducer

The function of the reducer is to transmit the power of the drawworks motor to the drum shaft through the gear coupling between the reducer input shaft and the drawworks motor. The drawworks motor can also drive the drum shaft together through the Eaton clutch.

3. Turntable chain box and angle transmission box

Its function is to transmit the power of the turntable motor to the angle transmission box through the clutch and gear coupling. The chain transmission pair uses a 2″ 3-row chain.

Features of drilling drawworks

1. The drum shaft is driven by an AC variable frequency motor through a gear reduction box. Under special circumstances, it can be driven by two motors in parallel. The lifting speed of the drum is continuously variable through the motor.

2. The intermediate shaft of the reduction box is equipped with an Eaton clutch to meet the requirements of lowering the empty elevator and drilling inching operations.

3. When drilling, the motor reverses and becomes a generator, which can act as an auxiliary brake for the drawworks for energy-consuming braking. Realize energy feedback to the power grid, reduce energy loss of the braking device, and save energy. If necessary, an Eaton 336WCB2 disc air brake can be installed on the right end of the drum shaft as the second auxiliary brake of the drawworks.

4. Use a double electric gear oil pump device to forcefully lubricate the gear reduction box.

5. The reduction box adopts a shrink disk structure and is connected to the drum shaft, which is safe and reliable and reduces the axial size.

6. The main brake adopts hydraulic disc brake. Two brake discs are centrally arranged at the left end of the shaft. Each brake disc is equipped with two working pliers and a safety gear, which are centrally controlled by the driller's room.

7. Equipped with over-roll valve type and digital anti-collision device, making the lifting operation safe and reliable.

8. The oil, gas and water pipelines are arranged under the decking in a place that is easy to maintain.

Sino Mechanical Equipment provides various oil drilling equipment, such as: drawworks,air winches, traveling block and hooks, wire rope, and accessories,etc. We are based in Shengli Oilfield, the second largest oil field in China, and provide high-quality drilling equipment and services to the world.