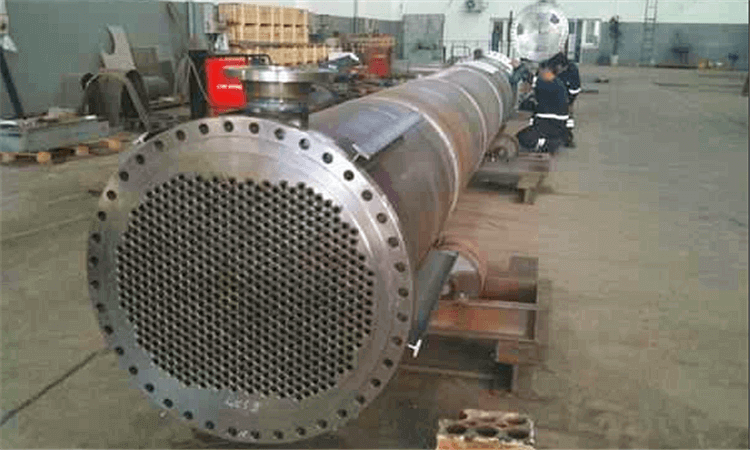

The Shell and Tube Heat Exchanger for the Middle East Project has been Fully Completed

Recently, we have successfully completed the comprehensive supply of shell and tube heat exchangers for a project in the Middle East. This achievement highlights our strength in the field of heat exchange technology and further validates our commitment to reliability.

As a forefront enterprise dedicated to heat exchange technology, Sino Mechanical has steadfastly aimed to provide exceptional products and solutions to our clients. Our shell and tube heat exchangers find extensive utilization in both comfort and industrial applications, offering dependable support for fluid heating and cooling processes.

The shell and tube heat exchangers deployed in this project boast the following prominent attributes:

1.High Efficiency and Energy Conservation: Our shell and tube heat exchangers showcase exceptional heat transfer performance, with heat transfer coefficients reaching 6000-8000 W/m²·°C, thereby achieving efficient energy-saving heat exchange processes.

2.Durable and Reliable: Crafted from stainless steel materials, these heat exchangers offer service lifetimes exceeding 20 years, delivering reliable equipment assurance to our clients.

3.Fluid Optimization: By transitioning laminar flow into turbulent flow, these heat exchangers enhance heat transfer efficiency while reducing thermal resistance.

4.Rapid Heat Exchange: Our shell and tube heat exchangers possess the capacity for swift heat exchange, demonstrating resistance to high temperatures (up to 400°C) and high pressures (up to 2.5 MPa).

5.Compact Structure: Characterized by a compact design, these heat exchangers occupy minimal space, are lightweight, and facilitate easy installation, consequently economizing on construction investment for clients.

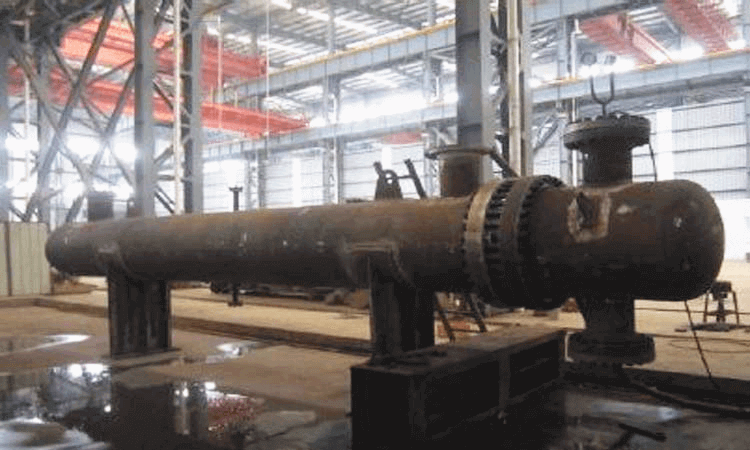

Throughout this project, our shell and tube heat exchangers have showcased remarkable flexible design and numerous outstanding advantages. Additionally, the integration of nano-thermal film technology has notably elevated heat transfer coefficients, further enhancing product performance.

Sino Mechanical's shell and tube heat exchangers find diverse applications across various domains, encompassing but not limited to thermal power, industrial and mining sectors, petrochemicals, urban centralized heating, food and pharmaceuticals, energy electronics, machinery, and light industries. Their adaptability to varied application conditions positions them as an optimal choice for numerous high-flow, high-temperature, and multi-medium heat exchange requirements in the Middle East region.

In this project, we've employed copper tubes boasting high thermal conductivity and extensive heat exchange area, with an outer surface characterized by a spiral finned structure. The optimization of the deflector's design has enhanced the efficiency and stability of the heat exchange process. Furthermore, even when handling oil-based fluids, our shell and tube heat exchangers exhibit commendable performance, particularly in applications involving low viscosity and clean oil-based heat exchange.

As a technology and quality-driven enterprise, Sino Mechanical will continue its commitment to offering innovative and dependable heat exchange solutions to our clients. Through this Middle East project, we've showcased our prowess and impact in the heat exchange field, while also fortifying a solid foundation for future collaborations. We eagerly anticipate more opportunities to provide higher quality products and services to our global clientele.