The Main Roles and Differences of Choke Lines and Kill Lines

Sino Mechanical is a globally renowned manufacturer and supplier specializing in choke lines and kill lines for over 20 years. With extensive experience in designing and manufacturing these critical components, Sino Mechanical offers a wide range of drilling equipment and provides OEM services. In this article, we will explore the primary functions and differences between choke lines and kill lines, shedding light on their applications and cost-effectiveness.

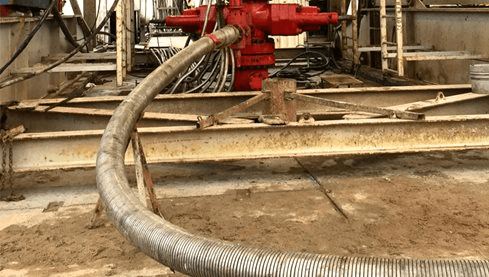

Choke Lines:

Choke lines play a crucial role in controlling the flow rate and pressure of fluids during drilling and production operations. The key functions of choke lines include:

Flow Regulation: Choke lines are equipped with adjustable choke valves that enable precise control over the flow rate of fluids. By manipulating the choke valve, operators can regulate the fluid flow to prevent pressure surges or maintain optimal production rates.

Pressure Management: Choke lines assist in maintaining pressure balance by creating backpressure on the well. This balance ensures the hydrostatic pressure exerted by the drilling mud column matches the formation pressure, preventing undesired wellbore influx and maintaining operational safety.

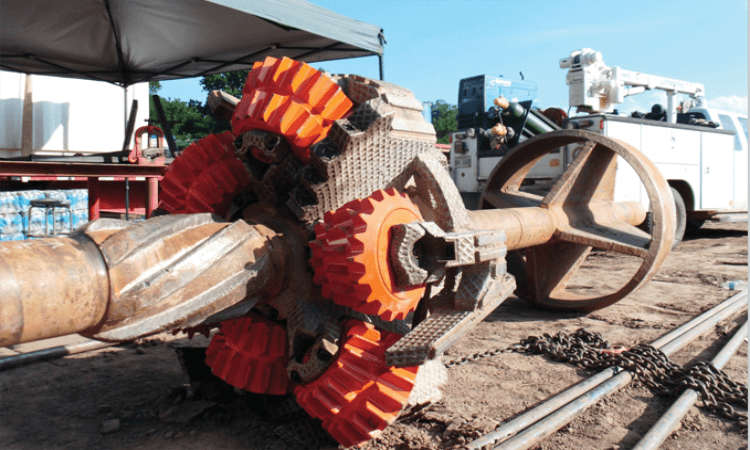

Kill Lines:

Kill lines serve a distinct purpose in well control operations, especially during emergencies such as blowouts. The primary functions of kill lines are as follows:

Well Killing: Kill lines are employed when there is an uncontrolled flow of formation fluids that needs to be stopped. Heavy fluids, such as specialized kill fluids or drilling mud, are pumped into the well through the kill line. This process increases the hydrostatic pressure within the well, effectively counterbalancing the formation pressure and regaining control of the well.

Well Shut-In: Kill lines enable the process of shutting in the well, which involves completely stopping the flow of formation fluids. By closing the blowout preventer (BOP) and introducing kill fluids through the kill line, pressure builds up in the well, restoring control and ensuring operational safety.

Differences between Choke Lines and Kill Lines: While choke lines and kill lines share similarities in their connection to the wellhead, their main functions and applications differ significantly:

Function: Choke lines primarily focus on flow regulation and pressure management during normal drilling or production operations. In contrast, kill lines are specifically designed for well control scenarios, aiming to stop uncontrolled flow and regain control of the well.

Application: Choke lines are utilized during routine operations to control fluid flow and maintain pressure balance. On the other hand, kill lines come into play during emergencies, such as blowouts, where immediate well killing and shutting in are necessary to mitigate risks.

Cost-Effectiveness: Both choke lines and kill lines are critical components in well control systems, ensuring operational safety. While their cost-effectiveness depends on various factors, including the scale of operations and specific requirements, investing in high-quality choke lines and kill lines from experienced manufacturers like Sino Mechanical can lead to long-term cost savings by ensuring reliable performance and minimizing downtime.

In summary, choke lines and kill lines serve distinct purposes within the well control system. Choke lines enable flow regulation and pressure management during routine drilling or production operations, while kill lines are crucial in emergency situations, facilitating well killing and shutting in. Understanding the differences between these components is essential for efficient well control practices. With Sino Mechanical's expertise and extensive experience as a global supplier, customers can rely on their high-quality choke lines and kill lines to ensure safe and effective well operations.