The Key Role of Drilling Spool in BOP Stack

The drilling spool plays a crucial role in the Blowout Preventer (BOP) stack, which is a vital safety system used in oil and gas drilling operations. Here are the key roles of a drilling spool in a BOP stack:

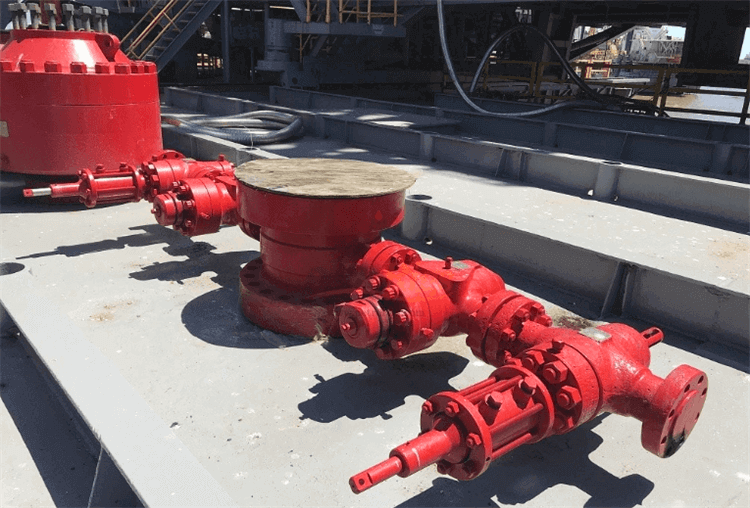

1.Pressure Control: Drilling spools help to maintain pressure control during drilling operations. They provide a means of connecting various components of the BOP stack, such as the BOP itself, choke manifold, and other pressure control equipment. By securely connecting these components, drilling spools enable the containment and control of wellbore pressure.

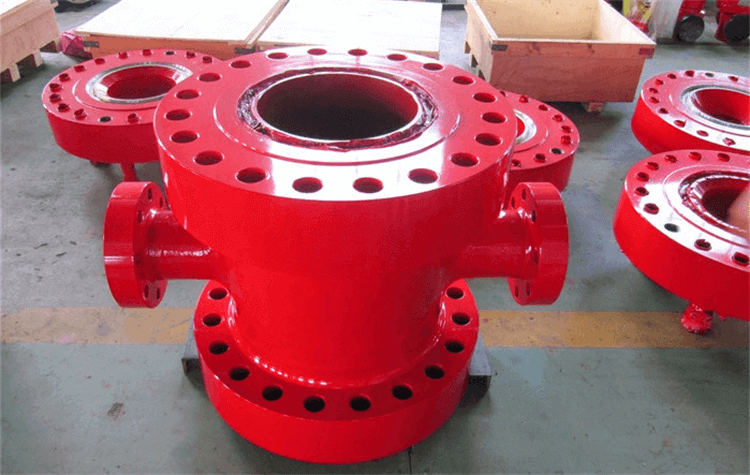

2.Flexibility and Adaptability: Drilling spools are available in different sizes and configurations, allowing for flexibility and adaptability in the drilling operation. They can accommodate various types and sizes of wellhead connections, casing hangers, and BOP equipment. This versatility enables the drilling spools to be customized to specific well requirements.

3.Reducing Height and Weight: Drilling spools are used to reduce the overall height and weight of the BOP stack. They provide a compact and streamlined connection between the BOP and the wellhead, which simplifies the overall design and improves the operational efficiency of the drilling rig.

4.Access for Maintenance: Drilling spools also provide access points for maintenance and repair activities. They allow for the removal and replacement of BOP components without the need to disassemble the entire BOP stack. This saves time and effort during maintenance operations and helps to minimize downtime on the drilling rig.

5.Well Control and Containment: During drilling, if an unexpected influx of fluids or a blowout occurs, the BOP stack, including the drilling spools, plays a crucial role in well control and containment. The drilling spools, in conjunction with other BOP components, help seal off the wellbore and prevent the uncontrolled release of hydrocarbons to the environment.

Overall, drilling spools are essential components of a BOP stack, providing pressure control, adaptability, access for maintenance, and facilitating well control and containment during drilling operations. They contribute to the safety and efficiency of drilling activities by connecting various components of the BOP stack and supporting the overall integrity of the wellbore.

.png)