The Application of Plunger Reciprocating Pump in Chemical Processes

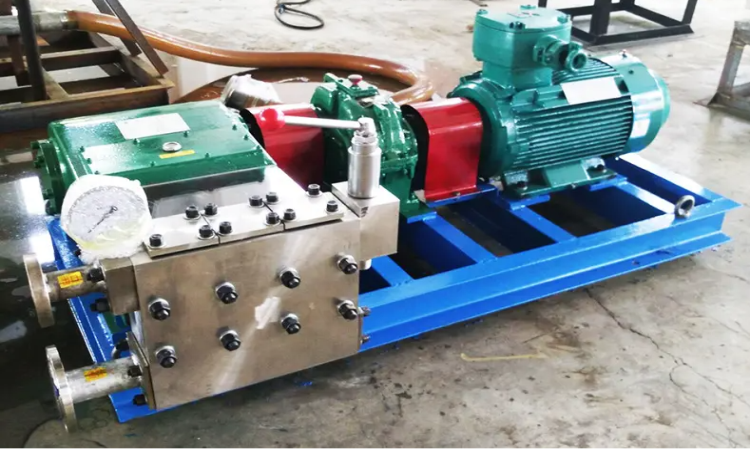

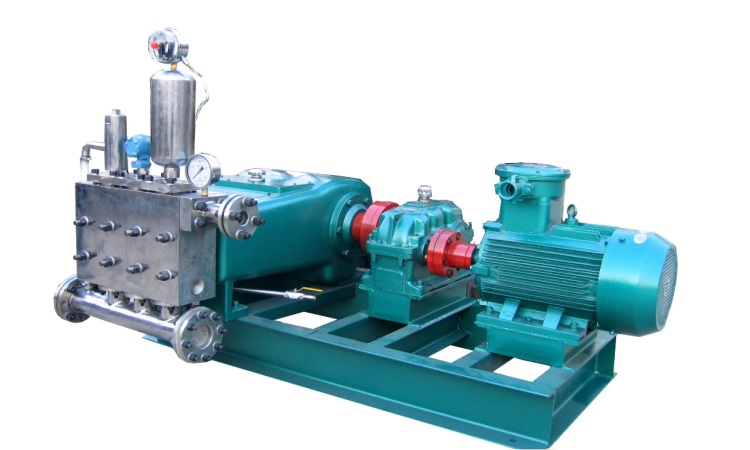

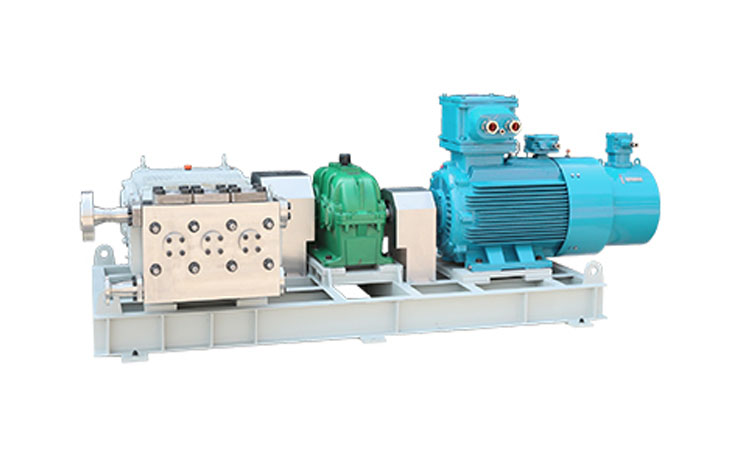

Plunger reciprocating pumps, also known as reciprocating positive displacement pumps, are widely used in various chemical processes due to their ability to handle high-pressure fluids and provide precise flow control. These pumps utilize a reciprocating motion of one or more plungers to create pressure and move fluids.

Here are some common applications of plunger reciprocating pumps in chemical processes:

Injection and dosing: Plunger pumps are extensively used for injecting chemicals or additives into chemical processes. They can accurately control the flow rate and pressure, making them suitable for applications such as injecting catalysts, pH adjusters, corrosion inhibitors, and other chemicals required for process optimization.

High-pressure pumping: Plunger pumps are capable of generating high pressures, making them ideal for processes that require pumping fluids under extreme pressures. They are commonly used in applications such as high-pressure homogenization, reactor feed, and pressure testing of pipelines and vessels.

Metering and proportioning: Plunger reciprocating pumps are often employed for precise metering and proportioning of chemicals in chemical processes. Their ability to deliver a consistent and accurate flow rate makes them suitable for applications such as blending, dilution, and precise chemical feed systems.

Hydrocarbon processing: Plunger pumps find significant use in hydrocarbon processing industries. They are utilized for various tasks, including transferring viscous crude oil, injecting chemicals for desulfurization, metering additives for fuel blending, and providing high-pressure lubrication to equipment in refineries and petrochemical plants.

Water treatment: Plunger reciprocating pumps are employed in water treatment processes to transport chemicals for disinfection, pH adjustment, coagulation, and flocculation. Their ability to handle a wide range of chemical additives and control flow rates accurately makes them suitable for water treatment applications.

Petrochemical and chemical feedstock processing: Plunger pumps play a crucial role in handling feedstocks and raw materials in the petrochemical and chemical industries. They are used for transporting various chemicals, including solvents, acids, caustics, and specialty chemicals, in processes such as distillation, extraction, and reaction.

Industrial cleaning: Plunger pumps are utilized in industrial cleaning processes, such as tank and vessel cleaning, where high-pressure water or cleaning solutions are required to remove stubborn deposits and contaminants. These pumps offer the necessary pressure and flow rate to effectively clean equipment and surfaces.

It is important to note that the selection of a plunger reciprocating pump for a specific chemical process depends on factors such as the nature of the fluid, required flow rate and pressure, temperature, chemical compatibility, and system requirements. Proper sizing, material selection, and maintenance are crucial to ensure safe and efficient pump operation in chemical processes.

Sino Mechanical, as a Reciprocating Pumps manufacturer, has more than 20 years extensive experiences in the performance, application and cost-effective manufacturing of Reciprocating Pumps.

If you want to know latest Reciprocating Pumps price, don’t hesitate to contact us anytime. We will get back to you within 24 hours.