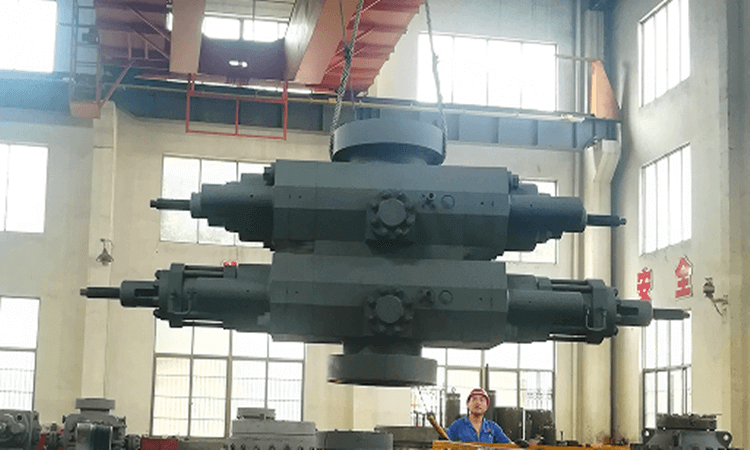

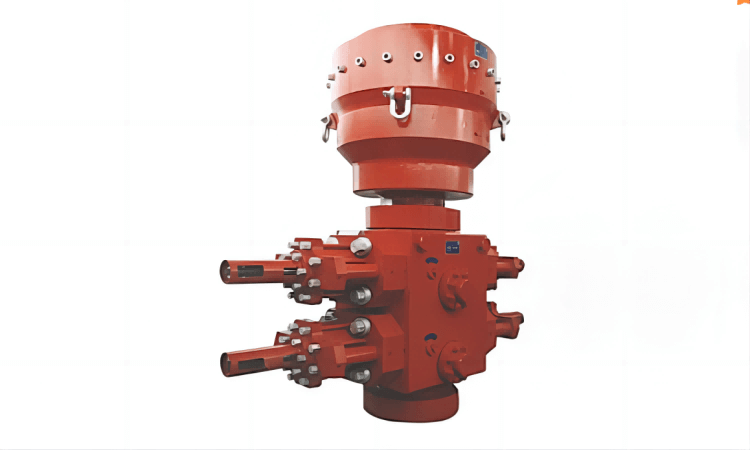

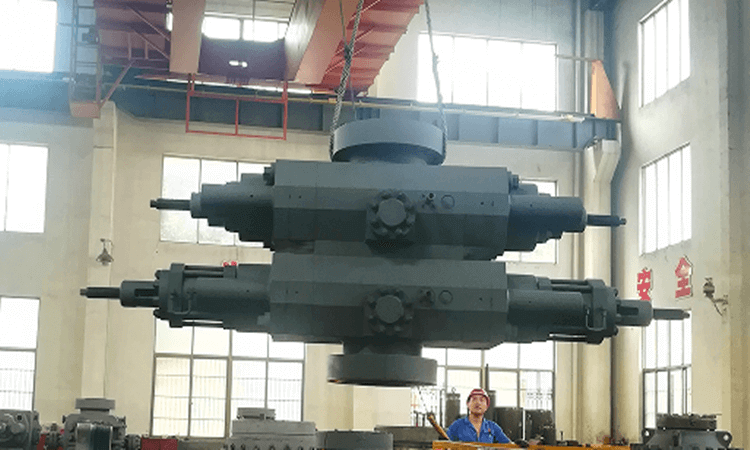

Six Common Ram BOP Failures, Causes, and Solutions

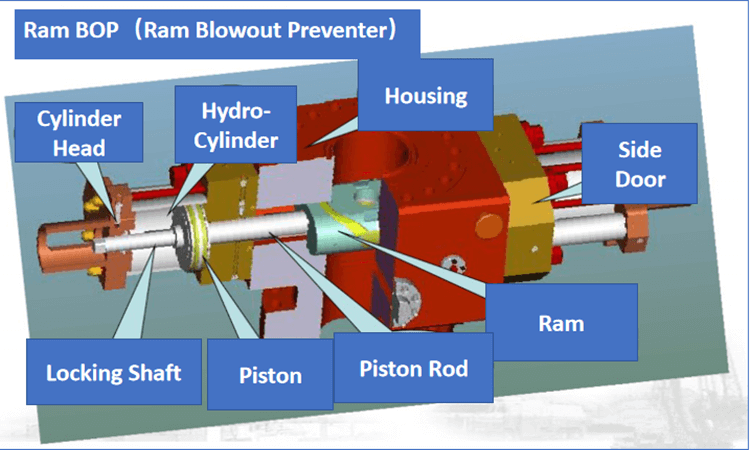

A Ram BOP is a device used to control the flow of fluids, typically employed in pipeline systems to prevent fluid jetting or leakage. Below are six common failures of Ram BOPs, along with their causes and solutions:

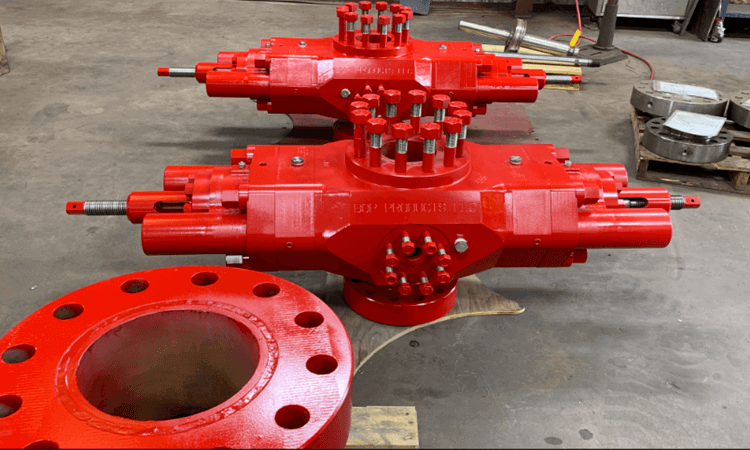

1. Damage to the sealing ring added to the connection between the Ram BOP's body and side gate.

Cause of the Failure: The sealing ring may become damaged due to prolonged use or improper installation.

Solution: Regularly inspect the condition of the sealing ring and replace any damaged ones as necessary to ensure the Ram BOP's sealing performance remains intact.

2. Bolts at the junction of the Ram BOP's body and side gate are not properly secured.

Cause of the Failure: Bolts may not have been correctly tightened, leading to an insecure connection between the Ram BOP's body and side gate.

Solution: Ensure that during installation and maintenance, the bolts are correctly tightened to ensure a secure connection between the Ram BOP's body and side gate.

3. Debris or damage to the sealing surface at the junction of the Ram BOP's body and side gate.

Cause of the Failure: Debris or damaged sealing surfaces can result in leaks.

Solution: Regularly clean the sealing surfaces of the Ram BOP's body and side gate, and ensure they are free from damage or contamination.

4. The actual direction of movement of the Ram BOP does not match the direction indicated on the control valve.

Cause of the Failure: Operators may misinterpret or incorrectly set the direction of movement for the Ram BOP.

Solution: Provide proper training and operating guidelines to ensure that operators understand how to correctly set up and operate the Ram BOP.

5. The Ram BOP cannot close completely.

Cause of the Failure: The Ram BOP may be obstructed by foreign objects or valve components may be damaged.

Solution: Inspect for any obstructions blocking the Ram BOP's movement and rectify or remove any obstructions. If valve components are damaged, they must be replaced or repaired.

6. Well media infiltrating into the oil cylinder, causing water and air to be present in the oil.

Cause of the Failure: Well media may infiltrate into the oil cylinder, leading to the presence of water and air in the oil.

Solution: Enhance the sealing of the well and oil cylinder to prevent well media from infiltrating the oil cylinder. Regularly inspect and maintain the oil within the cylinder and replace contaminated oil as needed.

In summary, regular inspection, maintenance, and proper operation are essential for preventing failures in Ram BOPs. Additionally, providing training to ensure operators understand the correct operation and maintenance procedures helps reduce the likelihood of failures and ensures the equipment's performance and safety.