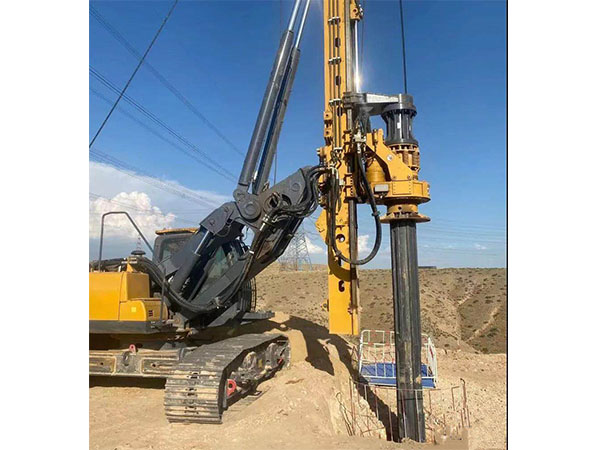

Sino Mechanical's rotary drilling rigs

What's rotary drilling rig?

Sino Mechanical's rotary drilling rigs are pile-driving machines used for on-site bored pile drilling in pile foundation projects. They have many functions and are suitable for the following scopes.

(1) Equipped with different drilling tools such as short spiral drill bits, spiral rotary buckets, core spiral drill bits, etc., and using corresponding drilling processes, they can be used for various clay, silt, fill, medium-density sandy soil, crushed stone soil, medium-hard weathered rock formations, dry (short spiral) or wet (rotary bucket), and rock formations (core drill) drilling operations.

(2) Equipped with a hydraulic pile hammer, it can be used for the construction of precast concrete piles or steel piles for building foundations.

(3) Equipped with a long spiral drill bit and a hydraulic grab bucket, it can be used for long spiral drilling and underground continuous wall construction respectively. Due to the above characteristics, as well as its safe, civilized, high-quality, low-pollution and high-efficiency construction, this equipment is widely used in the foundation construction of large-scale key projects such as roads, bridges, docks, and high-rise buildings. At present, it has become the main hole-forming equipment for bored pile construction in developed countries.

Structural form of Sino Mechanical's rotary drilling rigs

The structural form of rotary drilling rigs is mainly caused by the different chassis structures. At present, the chassis structure of rotary drilling rigs can be roughly divided into the following two categories:

(1) Special chassis structure. The product characteristics formed by this chassis structure are: the main and auxiliary winches are installed on the rotating platform, the overall structure layout is more reasonable; the overall working stability of the whole machine is good.

(2) Select the existing similar excavator or crawler crane chassis structure. In order to adapt to the construction requirements of rotary drilling rigs, the structure of this chassis must be modified accordingly, and the main and auxiliary winches can only be installed at the bottom of the drill mast or on the boom tripod, so that the working center of gravity of the whole machine moves forward and the stability is poor.

Sino Mechanical's rotary drilling rigs will embody the following characteristics in terms of structure and control system. (1) The chassis structure adopts a special design to enhance the structural rigidity and working stability of the whole machine; (2) The function realization and operating system and interface design are more humanized; (3) The control system is developing in the direction of management informationization, operation automation, and monitoring intelligence.

2. Main structural principles of Sino Mechanical's rotary drilling rigs

(1) Chassis.

The chassis adopts a special crawler retractable chassis structure, which is independently designed by Sino Mechanical. The four wheels and one belt are imported parts. It has the characteristics of reliable structure, good rigidity, large bearing capacity and good stability.

(2) Turntable.

The turntable mainly includes a slewing reducer, a slewing bearing, a turntable body, a drill mast support, etc. Its function is to bear the upper weight and make it slew. The turntable of this machine is adapted to the special chassis structure, and the main and auxiliary winches can be installed inside, and sufficient installation space for the main and auxiliary winches is ensured. It not only ensures the reasonable arrangement of the whole machine structure and center of gravity, and good working stability, but also makes the main and auxiliary winch drums adopt large diameter structures to reduce the number of winding layers of wire rope on the drum, reduce the mutual extrusion and friction of wire rope from the structural design, and increase the service life of wire rope.

(3) Drill mast and luffing mechanism.

The drill mast adopts a box-shaped section with three sections. The upper goose head and the lower drill mast and the main drill mast adopt a folding structure.

a. The lower hinge seat of the drill mast luffing cylinder is coaxial with the upper hinge shaft of the boom, with a simple structure, easy disassembly and assembly, and convenient maintenance;

b. When the drilling rig is transported or transferred to another site for assembly, it can use its own power and structure without the assistance of a crane to realize the self-loading and self-unloading function of the lower drill mast and the main drill mast when the main drill mast is less than 90° inclination (the drill mast is in a backward tilted state), which reduces the customer's use cost and improves the stability of the equipment during loading and unloading.

c. The driving force of the drill mast is increased through the optimized design of the drill mast, boom, tripod, each boom cylinder and each hinge point of the connecting rod, ensuring that the drill mast can be lifted and adjusted at any position of the drill mast. This ensures that the machine has a large working radius and strong adaptability.

(4) Main and auxiliary winches.

The main winch adopts a large-diameter drum structure. The wire rope for a drilling depth of 60 meters is wound in a single layer on the drum, which effectively solves the mutual extrusion and wear between the wire ropes of the multi-layer winding structure and ensures the service life of the wire rope. . The main winch can achieve dual-speed control and has a free lowering function to meet the needs of drilling. The control method is hydraulic pilot control, and the main and auxiliary winches are equipped with rope pressure devices.

(5) Power head.

The power head mainly includes a bracket and a driver. The hydraulic motor is driven by the hydraulic pump, and after passing through the reducer and drive gear, it is transmitted to the drill pipe through the casing drive shaft in the form of low speed and high torque.

It is applicable to both machine lock and friction drill pipes.

(6) Drill rod.

Generally, domestically made drill rods with reliable quality are selected. Drill rods with machine lock and friction structures can be selected according to user needs. Imported drill rods can also be selected according to user requirements.

(7) Drill bit.

The structure of the drill bit is very complex and there are many types. Depending on the construction geology, the applicable drill bit structure also varies greatly. Therefore, the rotary drilling bit should generally be selected according to the geological conditions of the project. The machine can be equipped with short spiral drill bits, rotary bucket drill bits, core drill bits, core rotary bucket and other drill bits of various specifications.

(8) Engine system.

The engine system provides power for the entire machine. The engine of the drilling rig is an internationally renowned brand.

(9) Hydraulic system.

All functions of the rotary drilling rigs are driven by hydraulics. The hydraulic system consists of three parts:

a. The lower part: mainly includes the central rotary body and the parts below, which can realize walking and crawler extension;

b. The upper part It can realize mast amplitude change, mast angle adjustment, drilling pressurization, main and auxiliary winches, vehicle rotation and rotation of power head;

c. Pilot control system: pilot control the main valves of the above two systems to make the operation light, flexible and smooth. The main hydraulic components such as hydraulic pumps, hydraulic motors and hydraulic valves are imported products produced by internationally renowned brand manufacturers to ensure reliable product performance.

Supplier of Rotary Drilling Rig

Sino Mechanical Equipment is a manufacturer engaged in the research and development and production of pile driving equipment. The company is located in Shengli Oilfield, the second largest oil field in China. Sino Mechanical Equipment has launched a variety of rotary drilling rigs. The company's products are widely used in various construction projects such as roads, railways, large power plants, steel mills, subways, high-rise buildings, etc. Product quality is the life of the enterprise, and technological innovation is the driving force for development. In order to meet the ever-changing market demand, the company can customize drilling rigs according to customer needs. At present, the products have spread all over the country and exported to countries and regions such as South America, Southeast Asia, West Asia, Africa and Europe.