Sino Mechanical solid control equipment mud mixing hopper maintenance

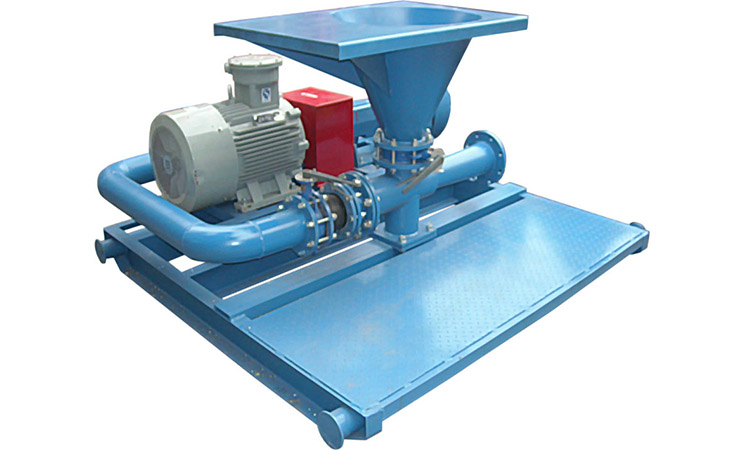

Sino Mechanical mud mixing hoppers/ jet mixing device

Sino Mechanical solid control equipment jet mixing device is also called mud mixing hopper. Its function is to configure or increase the total amount of drilling fluid, change the density, viscosity, water loss, etc. of drilling fluid. The jet mixing device is used in conjunction with the solid control system of oil drilling. It can meet the weighting and preparation of drilling fluid in the solid control system of 1500 meters to 6000 meters.

Sino Mechanical mud mixing hoppers selection

Choose a Sino Mechanical solid control equipment jet mixing device suitable for the drilling fluid system. Usually, for most drilling equipment, one funnel is enough. If the drilling fluid circulation displacement is greater than 120Qgal/min, then consider using a funnel with a capacity of 1200gal/min. Usually, there is no need to add chemicals faster than this. For most work, 600~800ga/min is enough. The effect is outstanding when used in conjunction with a shear pump. The equipment is conventionally manufactured as a single-joint structure. When the mud processing volume is too large, it can be designed as a double-joint jet mixing device.

Selection of mud mixing hoppers installation location

Keep the distance between the pipeline and the funnel as short and straight as possible. The pump and motor should be selected based on the pressure head and flow rate required by the system. In all jobs, venturi tubes are very beneficial, especially when the system back pressure will reduce the working efficiency of the drilling fluid funnel. The venturi tube allows the fluid to move vertically to a higher height of the funnel. In many cases, the funnel is placed in a horizontal direction, and the downstream pipeline is placed at or above the height of the top of the drilling fluid tank.

Sino Mechanical solid control equipment jet mixing device maintenance

1. Use new and clean accessories to reduce friction losses. Flush the entire system with clean fluid after each work to prevent the drilling fluid from drying and clogging the system. Clean the throat of the funnel to prevent the material from cementing, otherwise the next time the funnel is used, the operation will be poor.

2. The workbench is connected and fixed near the funnel to support the bagged material. The workbench should have a suitable height, 0.9~1.0m, so that the staff can easily add the material with little physical effort. Power-assisted carts and bag handlers can increase the speed of addition and reduce the workload of staff.

3 Like drilling equipment, make a plan for regular maintenance and inspection of the jet mixer. The jet mixer is generally simple and easy to operate, but worn nozzles and valves will affect the work. Check once every 30 to 60 days, and spare a nozzle, i valve and casing brush.

4. The installation of the inlet and outlet pipelines should be smooth and unobstructed to avoid vortexes.

5. The distance between the nozzle and the end face of the Venturi tube should be adjusted to 32-80mm.

6. When adding materials by force, the feeding speed should be controlled and not exceed the required mixing processing volume to ensure a good mixing effect.

7. After the ingredients or liquid supply are completed in winter, the plug under the tee should be opened in time to drain the residual liquid to avoid freezing the equipment.

8. After use, the funnel should be rinsed with clean water to avoid clogging the equipment after the mud is dried.

Supplier of Mud mix hoppers

Sino Mechanical Equipment is a supplier of Mud mix hoppers, providing various types of Solids Control equipment to meet various requirements of drilling work for solids control systems. Sino Mechanical Equipment is based on Shengli Oilfield, the second largest oilfield in China, and provides high-quality oil equipment and services to the world.