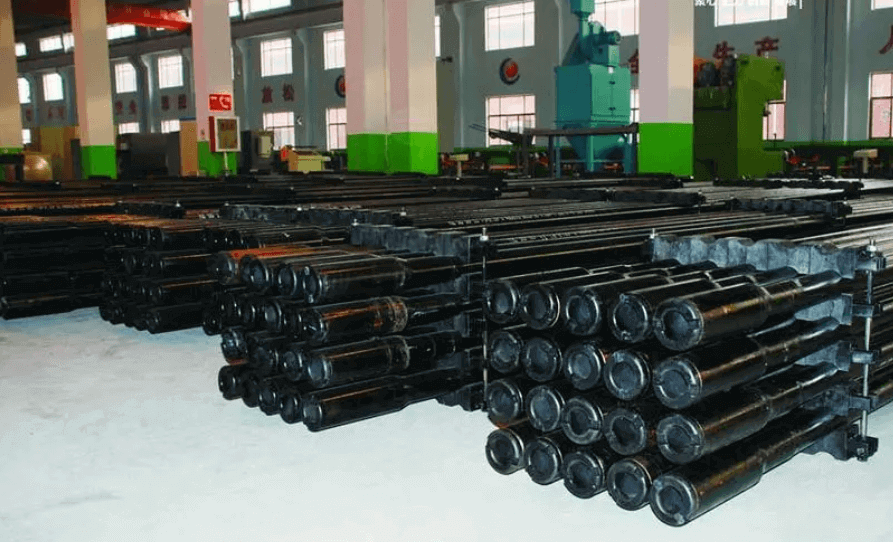

Sino Mechanical: Drill Pipe Solutions for Improved Drilling Efficiency and Reduced Operational Costs

In drilling operations, as easily worn parts, drill pipes often need to be replaced, which brings many troubles to users. Not only does it affect drilling efficiency, but it also increases customer operating costs. Therefore, when choosing drill pipes, good wear resistance and ultra long service life have become the focus of customer attention. In response to this issue, as a drill pipe supplier, Sino Mechanical has taken a series of measures to improve the wear resistance and service life of drill pipes, in order to meet customer needs and reduce customer operating costs.

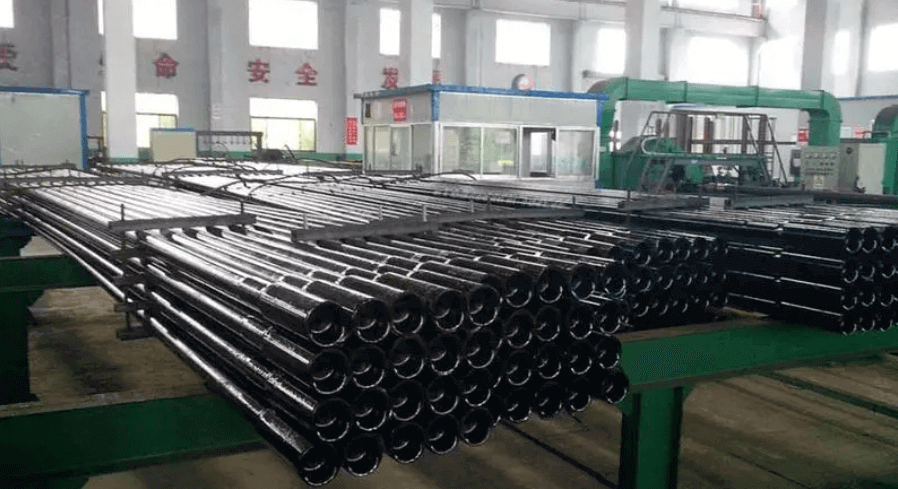

1.Material selection and manufacturing process optimization:

Sino Mechanical selects high-strength, wear-resistant, and corrosion-resistant materials, combined with advanced manufacturing processes, to ensure the quality and performance of drill pipes. Through optimizing heat treatment processes, improving welding quality, and enhancing surface treatments, Sino Mechanical's drill pipes exhibit higher durability and resistance to wear.

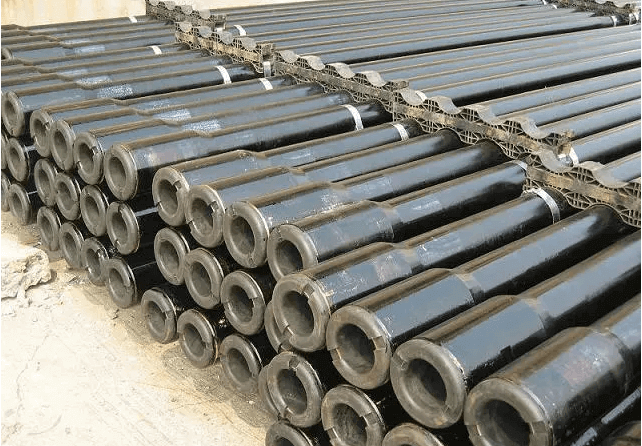

2.Structural design and connection method improvement:

Sino Mechanical optimizes the structure and connection methods of drill pipes to enhance their strength and reliability. By employing more reliable connection designs, adding reinforcement sections, and changing the connection methods, drill pipes are ensured to have better compressive capacity and durability when subjected to stress and wear.

3.Technical support and training:

Sino Mechanical provides comprehensive technical support and training to customers, helping them use and maintain drill pipes correctly. From proper installation and disassembly methods to the best practices for drilling operations, Sino Mechanical's professional team offers guidance to customers, ensuring the long-term use of drill pipes and reducing the risk of damage.

4.Regular inspection and maintenance plans:

Sino Mechanical collaborates with customers to establish regular inspection and maintenance plans. Regular inspections enable timely detection and repair of wear, fatigue, or other potential issues with drill pipes, thus reducing the risk of damage and failures while extending the lifespan of drill pipes.

Advantageous comparison:

Compared to other suppliers, Sino Mechanical's drill pipe solutions have significant advantages. Firstly, Sino Mechanical selects high-quality materials and utilizes advanced manufacturing processes, ensuring superior quality and performance of drill pipes. Secondly, through optimized design and connection methods, drill pipes exhibit higher strength and reliability. Additionally, Sino Mechanical's technical support and training services assist customers in correctly using and maintaining drill pipes, reducing operational costs. Finally, regular inspection and maintenance plans ensure that drill pipes remain in good condition, thereby prolonging their lifespan.

Sino Mechanical is committed to providing high-quality drill pipe solutions to improve customers' drilling efficiency and reduce operational costs. Through material selection optimization, manufacturing process improvement, design and connection method optimization, provision of technical support, and regular maintenance, Sino Mechanical's drill pipes possess notable advantages in terms of durability and performance. Whether in complex geological conditions or high-intensity operational environments, Sino Mechanical's drill pipes help customers achieve more efficient, reliable, and cost-effective drilling operations.