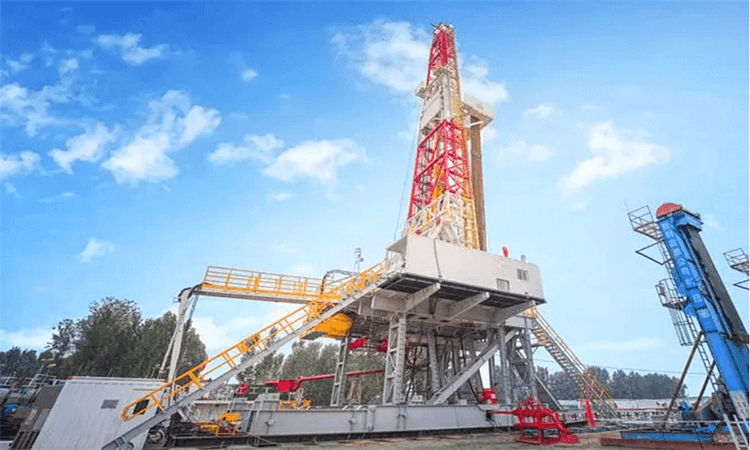

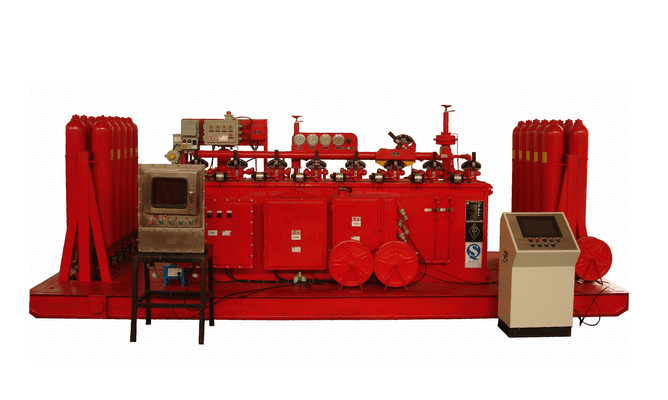

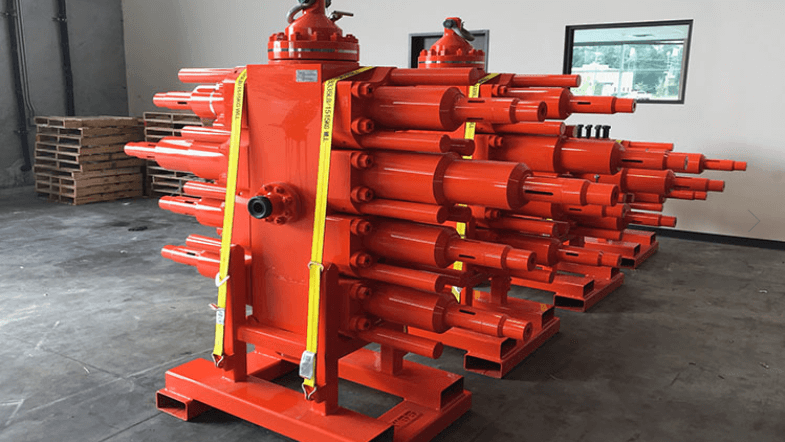

Sino Mechanical: A Premier Supplier of High-Pressure Well Control Solutions

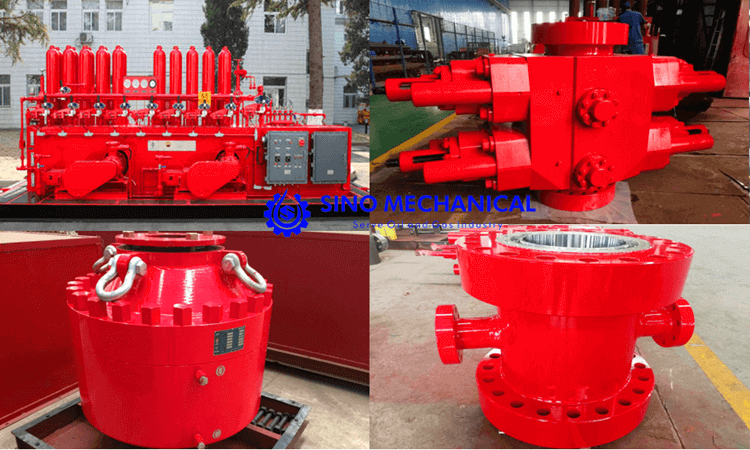

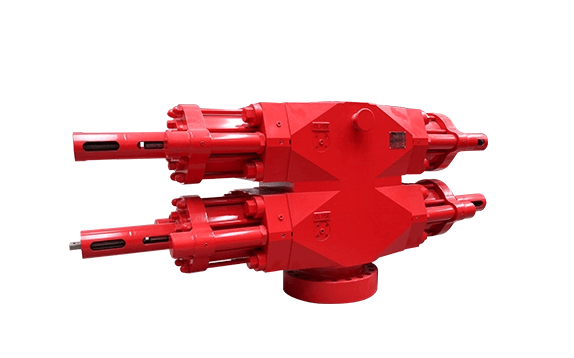

In the realm of modern energy exploration, the Wellhead Blowout Preventer (BOP) unit stands as a paramount component for maintaining high-pressure well control. Sino Mechanical, renowned for its excellence, designs and manufactures top-tier pressure control equipment tailored to meet the demands of high-pressure environments. Our product range includes BOP stacks, annular BOPs, ram BOPs, drilling spools, Koomey units, multiplex control systems, as well as wellhead equipment, all engineered to cater to rigorous well control requirements.

In oil drilling operations, blowout is a serious accident that may pose a serious threat to life and the environment. In order to ensure the safety of drilling operations, wellhead blowout prevention units have become a crucial technology. The use of wellhead blowout preventer units can effectively prevent the occurrence of blowout accidents and ensure the safe operation of drilling personnel.

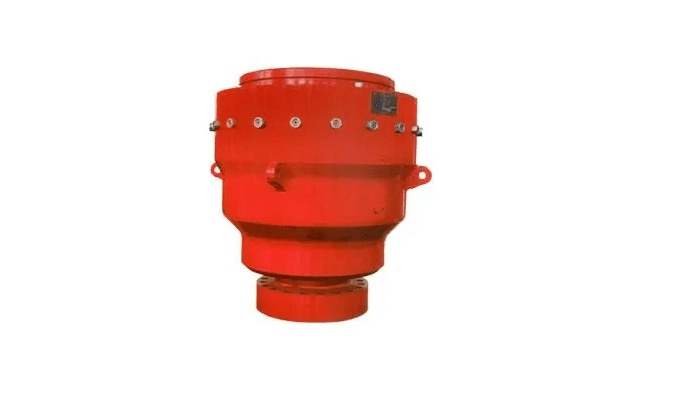

The wellhead blowout preventer unit is a specially designed equipment that plays a key role in controlling the wellhead pressure during the drilling process. When the bottom hole pressure suddenly increases or exceeds the pressure of the drilling fluid, the wellhead blowout preventer unit will automatically start, quickly closing the wellhead, and preventing the gushing liquid from gushing out. It restricts the release of pressure in the well by urgently closing the wellhead, thereby effectively preventing the occurrence of blowout accidents.

The working principle of the wellhead blowout preventer unit is based on the principles of rapid response and emergency sealing. It usually consists of multiple key components, including emergency shut-off valves, wellhead stoppers, blowout nozzles, etc. When the bottomhole pressure abnormally increases, the device will automatically detect pressure changes and quickly initiate corresponding control measures. The emergency shut-off valve will quickly close the wellhead, sealing the pressure inside the wellbore to prevent further release of pressure. The wellhead plugging device plays a role in sealing the wellhead and preventing the overflow of well kick liquid. The blowout prevention nozzle can rapidly spray high-pressure foam to kill slurry when the wellhead pressure rises, forming a blowout prevention barrier and slowing down the development of blowout accidents.

The use of wellhead blowout preventer unit has multiple advantages. Firstly, it can quickly respond to changes in bottom hole pressure, automatically start and seal the wellhead, reducing the risk of blowout accidents. Secondly, it has reliability and stability, which can play a role in critical moments and ensure the safety of drilling personnel. In addition, the use of wellhead blowout prevention devices can improve operational efficiency, reduce downtime and resource losses.

However, relying solely on wellhead blowout preventer unit is not enough to ensure the complete avoidance of blowout accidents. Drilling personnel should also strengthen training to improve their understanding and ability to respond to blowout. They should be familiar with well control procedures and safety regulations, be able to quickly and accurately determine changes in bottom hole pressure, and take timely control measures. In addition, continuous monitoring of bottom hole pressure, strengthening team communication and collaboration, and regular maintenance of wellhead blowout preventer units are all important steps to ensure the prevention of blowout accidents.

In summary, wellhead blowout preventer units are a key safety technology that plays a crucial role in drilling operations. It can quickly respond to changes in bottom hole pressure, protect the safety of drilling personnel, and reduce the occurrence of blowout accidents. However, the effective use of wellhead blowout preventer needs to be combined with other safety measures, strengthen training and communication, and ensure the safety awareness and resilience of the entire drilling team. Only by comprehensively considering various factors and preventing blowout accidents can safe and efficient drilling operations be achieved.

Well control equipment developed by Sino Mechanical, which can meet the well control process requirements of high pressure oil and gas drilling.

When the BOP is applied on site, it can be used in multiple combinations according to the needs, including rotary BOP, ram BOP, double ram BOP, annular BOP and four-way etc.

Sino Mechanical aims to provide you with high quality and best price BOP Stacks. If you are looking for BOP Stacks or BOP Stacks spares, please kindly contact us to get the latest BOP Stacks price.