Single Screw Pumps: A Versatile Solution for Fluid Conveyance

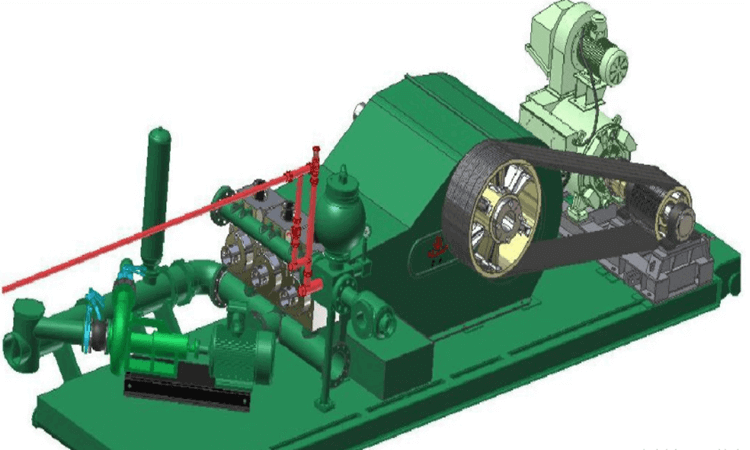

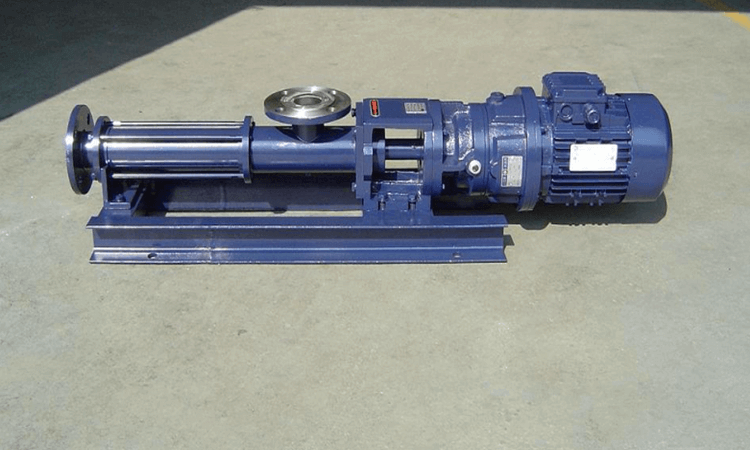

1. Working Principle:

At the heart of a single screw pump is a helical rotor that rotates within a double-threaded stator. This simple yet effective design ensures positive displacement, where fluid is continuously pushed from the pump's inlet to its outlet.

2. Positive Displacement Efficiency:

The positive displacement mechanism guarantees a consistent and uniform flow rate, making single screw pumps ideal for applications where precision and reliability are paramount.

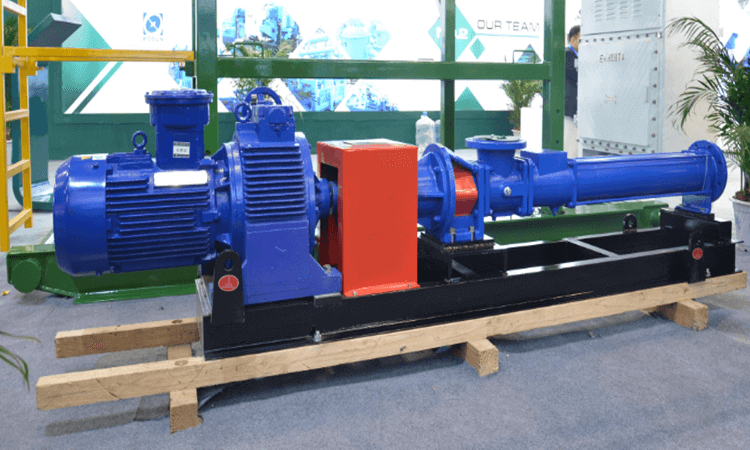

3. Seamless Fluid Handling:

One of the standout features of single screw pumps is their ability to handle a variety of fluids, including shear-sensitive, high-viscosity, and solids-laden substances. The gentle pumping action minimizes the risk of fluid damage, preserving the integrity of the conveyed material.

4. Versatility Across Industries:

These pumps find applications across diverse industries such as oil and gas, wastewater treatment, food processing, and chemical manufacturing. Their versatility stems from the ability to handle challenging fluids, making them a go-to solution for complex fluid conveyance needs.

5. Reversible Flow Capability:

Depending on the specific design, some single screw pumps are capable of reversible flow. This flexibility further enhances their suitability for processes that may require bidirectional fluid movement.

6. Low Maintenance and Longevity:

The simplicity of the design contributes to the ease of maintenance, and the robust construction materials ensure longevity. Single screw pumps are known for their durability, providing a cost-effective solution over the long term.

7. Environmental Considerations:

In addition to their operational efficiency, single screw pumps often contribute to environmental sustainability. Their ability to handle a range of fluids makes them suitable for wastewater treatment and other processes aimed at reducing environmental impact.

In conclusion, single screw pumps play a crucial role in fluid conveyance, offering efficiency, versatility, and reliability across various industries. As technology continues to advance, these pumps remain at the forefront, meeting the evolving needs of fluid handling processes and contributing to the efficiency and sustainability of industrial operations.