Series of Tests for Double Ram BOP Before Factory Delivery

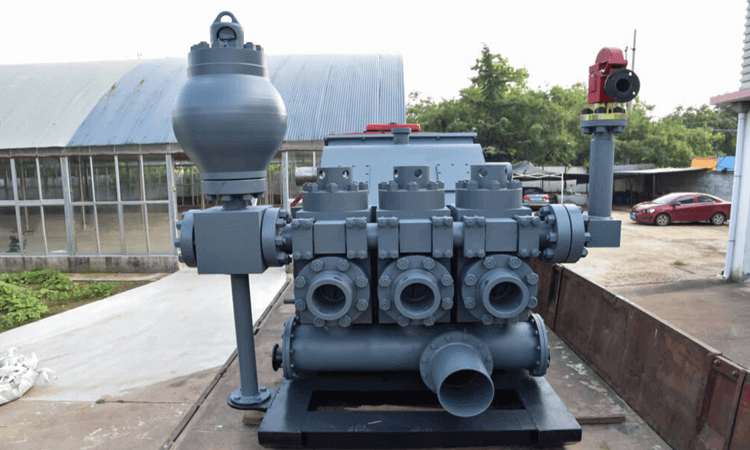

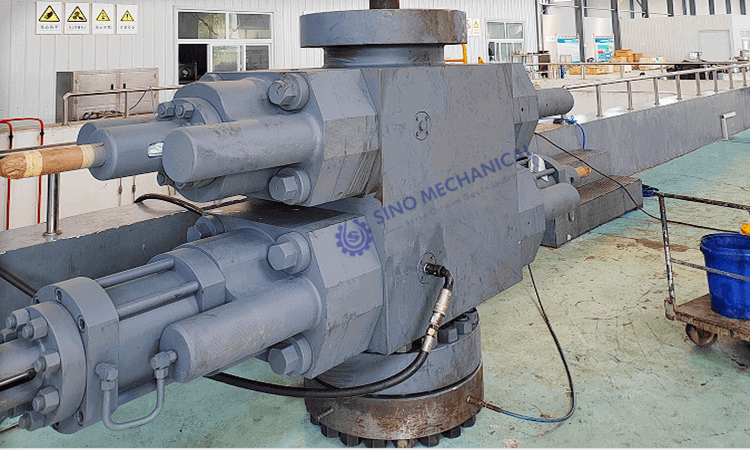

A Russian customer has placed an order with Sino Mechanical for a set of 10,000 psi Double Ram BOP. This blowout preventer is equipped with a set of blind rams and shear rams with a series of inline boosters, and it belongs to a specific type of blowout preventer commonly used in oil and gas well control systems. Its primary function is to swiftly cut off wellhead pressure by shearing through pipelines to prevent wellhead blowouts and control well pressure. Shear ram BOPs typically consist of two blade-like rams that cut through the pipeline by applying substantial pressure, designed to cut oil pipes or drill pipes when the BOP is closed.

The Double Ram BOP has been successfully delivered, but in order to ensure the reliability and safety of the ram blowout preventer, we conducted a series of tests and verifications according to specific working conditions, and were supervised and recorded by professional technical personnel.

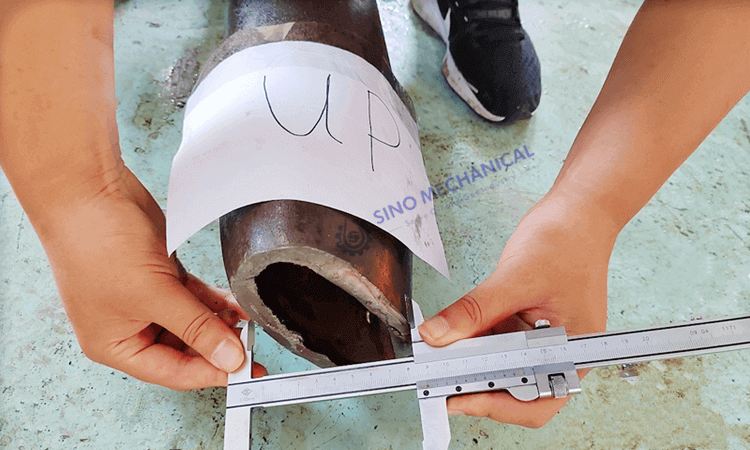

Shearing Capability Test: This is one of the most crucial tests. In this test, the shear ram blowout preventer is used to cut through a simulated pipeline or test material to verify its shearing capability complies with design requirements. This test is typically conducted under high-pressure conditions to simulate real operational conditions.

Material Inspection: Inspection of the materials used in the shear ram BOP to ensure they meet relevant standards and specifications. This includes testing for material strength, corrosion resistance, and other relevant properties.

High-Pressure Testing: Prior to factory delivery, shear ram BOPs are typically subjected to high-pressure testing to ensure they can operate smoothly under rated working pressures without leaks or damage.

Response Time Test: The response time of the shear ram BOP is critical, as it needs to quickly cut off the pipeline in emergency situations. Response time testing measures the time taken from triggering the device to cutting off the pipeline, ensuring it is completed within specified timeframes.

Corrosion-resistant Coating Inspection: If the equipment has corrosion-resistant coatings on its surface, the quality and integrity of these coatings are inspected to ensure the equipment can withstand harsh environmental conditions for extended periods.

These ram blowout preventers play a critical role in wellhead control systems, particularly in emergency situations such as wellhead blowouts or unstable wellhead pressures. They can rapidly sever pipelines, preventing the escalation of hazardous situations and thereby safeguarding the safety of personnel and equipment.

In comparison to ram blowout preventers, shear ram BOPs have distinct differences in their working principles and purposes:

Shear ram BOPs are primarily used in emergency situations within oil and gas well control systems, such as wellhead blowouts or uncontrolled wellhead pressure. The shear ram blowout preventer operates similarly to scissors and is utilized to rapidly cut off fluid flow to prevent wellhead blowouts.

Conversely, standard ram blowout preventers are typically used for fluid control during routine operations, such as regulating fluid flow in wellheads, pipelines, or industrial processes. They primarily adjust fluid flow by opening or closing a gate or ram.

Whether you require a shear ram BOP or a standard ram BOP, Sino Mechanical can provide you with the necessary equipment. Our company can produce a full range of U-shaped structure products and their accessories, and the accessories are interchangeable. If you would like to inquire about the latest Ram BOP prices, please feel free to contact us.