Reciprocating pumps for oilfield water injection

What is a reciprocating pump?

Reciprocating pumps are positive displacement pumps. That is to say, it also achieves the purpose of transporting liquid by means of periodic changes in the volume of the working chamber: the mechanical energy of the prime mover is directly converted into the pressure energy of the transported liquid through the pump; the flow rate of the pump only depends on the change value of the working chamber volume and its The number of changes (frequency) per unit time, independent of (theoretically) the discharge pressure. The difference between a reciprocating pump and other types of positive displacement pumps lies only in the way it changes the volume of the working chamber and its structural features: a reciprocating pump relies on the reciprocating motion of the piston (plunger) in the working chamber of the liquid cylinder (or through a diaphragm, The periodic elastic deformation of flexible elements such as bellows in the working chamber causes periodic changes in the volume of the working chamber. Structurally, the working chamber of the reciprocating pump is separated from the outside world by a sealing device, and communicates or is closed with the pipeline through the pump valve (suction valve and discharge valve).

Features of reciprocating water injection pump

(1) The instantaneous flow rate is pulsating. This is because in the reciprocating pump, the suction and discharge processes of the liquid medium (i.e., the volume change process) are carried out alternately, and the plunger's speed is constantly changing during the displacement process. middle. In a pump with only one working chamber (single-cylinder pump), the instantaneous flow rate of the pump not only changes with time, but also is discontinuous; in a pump with multiple working chambers (multi-cylinder pump), if the working chamber With appropriate phase arrangement, the pulsation amplitude of the instantaneous flow in the discharge collection pipe can be reduced, and can even reach a point where it can be considered as a stable flow in practice. Of course, the corresponding pump structure becomes complicated at this time. Because of this, the working chamber of the reciprocating pump should not be set too much. Therefore, the pulsation of the instantaneous flow rate of the reciprocating pump is inevitable, but the degree of pulsation varies depending on the pump type.

(2) The average flow rate (that is, the flow rate of the pump) is constant. It can be seen from the way and structural characteristics of the reciprocating pump that changes the working chamber volume. When the design of the pump is reasonable and the manufacturing quality is good, the flow rate of the pump only depends on the working chamber volume. The changing value and its frequency have nothing to do (in theory) with the discharge pressure, and have nothing to do with the temperature, viscosity and other physical and chemical properties of the transport medium (liquid). When the number of reciprocations of the pump per minute is constant, the flow rate of the pump is also constant. Due to the limitations of plunger sealing technology, pump valve, cylinder body and other design technologies and material strength, the working chamber volume of the reciprocating pump should generally not be too large (especially at high pressure), and the number of working chambers should not be too many. The number of reciprocations should not be too high. Therefore, the flow rate of the pump cannot be very large.

(3)The pressure of the pump depends on the pipeline characteristics

The flow rate and head of a centrifugal pump are limited by the pump itself, and the two are closely related. The reciprocating pump is different. Its discharge pressure cannot be limited by the pump itself, but depends on the pipeline characteristics of the pump device and has nothing to do with the flow rate. In other words, no matter how much hydraulic resistance the pipeline of the pump device has, in principle the pump can discharge at a constant flow rate determined by its main structural parameters. That is to say, if the transported liquid is considered to be incompressible (because the compressibility of the liquid is very small, this can usually be considered, but under high or ultra-high pressure, the compressibility of the liquid cannot be ignored), then in theory it can be considered as reciprocating The discharge pressure of the pump will not be subject to any restrictions, and any required discharge pressure of the pump can be established according to the piping characteristics of the pump device.

Of course, when the reciprocating pump actually leaves the factory, there is a regulation on the discharge pressure of the pump. This does not mean that the discharge pressure of the pump will not increase again, but it just means that due to the rated power of the prime mover (or other power Source parameters) and the structural strength of the pump itself (including all pressure-bearing and force-bearing parts at the liquid end and transmission end) do not allow use above this discharge pressure.

(4) It has strong adaptability to the transported medium (liquid). In principle, the reciprocating pump can transport any medium and is almost not limited by the physical or chemical properties of the medium. Of course, in practical applications, sometimes we encounter situations that cannot be adapted. However, when encountering this situation, it is mostly because the materials, manufacturing processes and sealing technology of the liquid end cannot be solved for the time being.

(5) Sino mechanical water injection pump has automatic protection function: Sino mechanical water injection pump is equipped with three automatic protection devices. When: discharge pressure is too high; suction pressure is too low; crankcase oil temperature is too high, the pump will automatically stop.

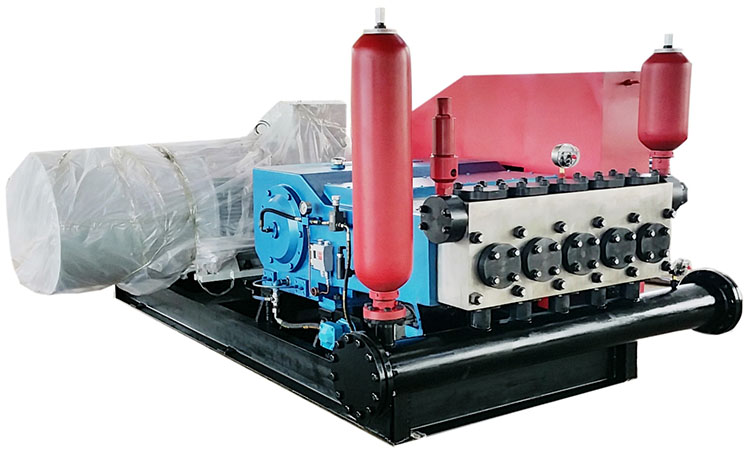

Structural composition of reciprocating water injection pump

The reciprocating water injection pump mainly consists of the power end assembly, the hydraulic end assembly, the base assembly and other parts.

The power end assembly consists of crankshaft, connecting rod assembly, crosshead assembly, connecting clip, plunger and other parts.

The connecting rod assembly is composed of connecting rod cover, connecting rod body, connecting rod shoe and other parts.

The crosshead assembly consists of a crosshead, crosshead bushing, crosshead pin, crosshead lifter, protective plate, plunger clip and other parts.

The liquid end assembly is mainly composed of pump head body, suction and discharge valve and other parts.

The packing box assembly is mainly composed of packing box, plunger, sealing packing and other parts.

Supplier of oilfield water injection pump

Sino Mechanical Equipment is a supplier of oilfield water injection pumps, providing reciprocating pumps,plunger pumps, diaphragm pumps,centrifugal pumps, screw pumps, etc. Sino Mechanical Equipment is based on Shengli Oilfield, the second largest oil field in China, and provides high-quality petroleum equipment and services to the world.