Reasons and Solutions for Seal Failure of Double Ram Blowout Preventers

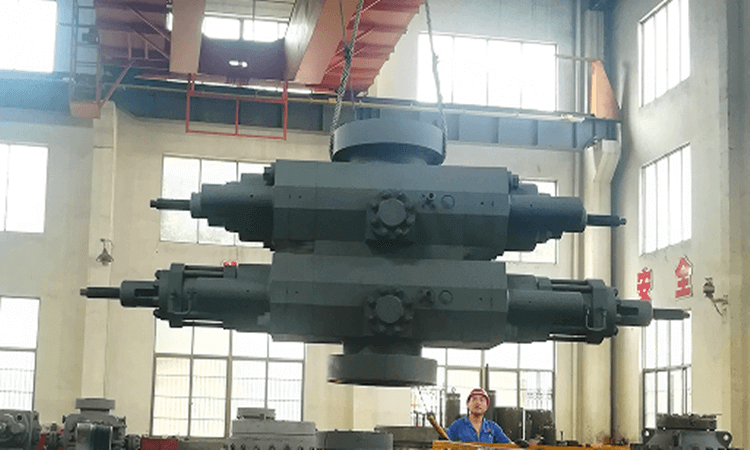

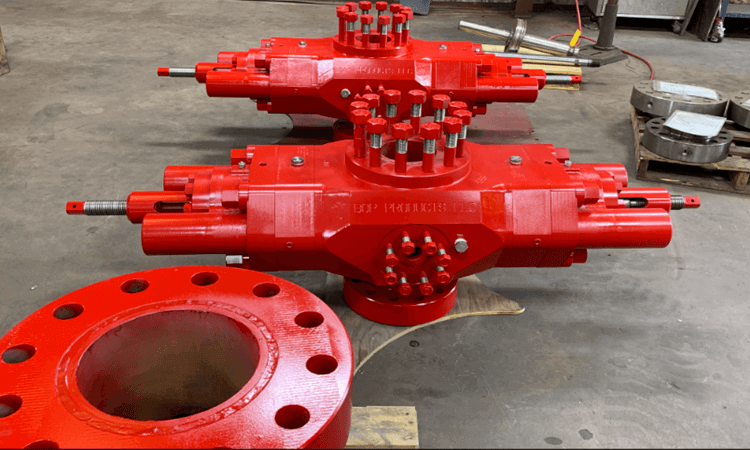

Blowout preventers (BOPs) are critical safety devices used in the oil and gas industry to control wellbore pressure and prevent uncontrolled oil or gas releases during drilling operations. Among the various types of BOPs, the Double Ram Blowout Preventer plays a crucial role in well control. However, ensuring the integrity of its seals is paramount to prevent potential blowouts. In this article, we will explore the reasons behind seal failures in Double Ram Blowout Preventers and propose effective solutions to mitigate these issues.

Types of Seals in Double Ram Blowout Preventers

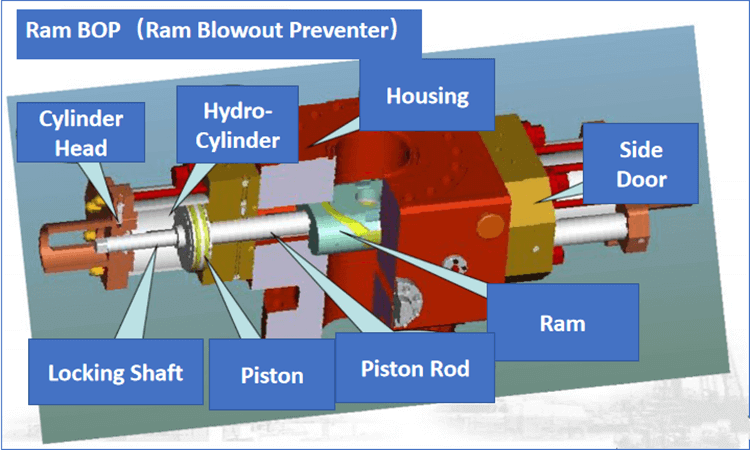

A Double Ram Blowout Preventer consists of multiple seals designed to isolate wellbore pressure effectively. The primary seals include:

Ram Seals: These are the central sealing elements that close around the drill pipe, casing, or other tubular components in the wellbore. Ram seals are pivotal for well control and preventing fluid escape.

Bonnet Seals: These seals are located between the upper and lower bodies of the BOP and are essential for maintaining the pressure integrity of the preventer.

Causes of Seal Failure

Seal failures in Double Ram Blowout Preventers can lead to catastrophic consequences. Several factors can contribute to these failures:

Wear and Tear: The constant opening and closing of the rams can lead to wear and tear on the seals over time. This wear can eventually compromise their sealing ability.

Improper Installation: Incorrect assembly or installation of the BOP can result in misalignment of the rams and seals, leading to leaks.

High Pressure and Temperature: Harsh drilling conditions involving high pressure and temperature can put excessive stress on the seals, causing deformation or material fatigue.

Corrosion and Erosion: The corrosive nature of drilling fluids or the presence of abrasive materials in the wellbore can lead to corrosion or erosion of the seal materials.

Solutions and Preventive Measures

To prevent seal failures in Double Ram Blowout Preventers, operators and drilling teams can take the following proactive steps:

Regular Inspections: Implement routine inspections of the BOP's seals, paying close attention to wear and tear. Replace worn seals promptly to maintain integrity.

Proper Installation: Ensure that the BOP is correctly assembled and installed following manufacturer guidelines and industry best practices to prevent misalignment.

Material Selection: Consider using high-quality, corrosion-resistant materials for seals when operating in corrosive environments. Consult with the manufacturer for suitable options.

Temperature and Pressure Management: Monitor and control wellbore conditions to prevent exposure to extreme temperatures and pressures that can damage seals.

Maintenance Training: Train personnel on proper BOP maintenance procedures, including the inspection and replacement of seals. Ensure that team members are knowledgeable about emergency response measures.

Seal failure in Double Ram Blowout Preventers can pose significant risks during drilling operations. By conducting regular inspections, following proper installation procedures, selecting appropriate materials, and providing training for maintenance and emergency scenarios, the industry can mitigate the risk of seal failures. This proactive approach ensures the safety and integrity of well control systems, preventing potentially disastrous blowouts in the oil and gas sector.