Precautions when installing the jet mixing device of Sino Mechanical solid control equipment

Sino Mechanical Jet mixing device Introduction

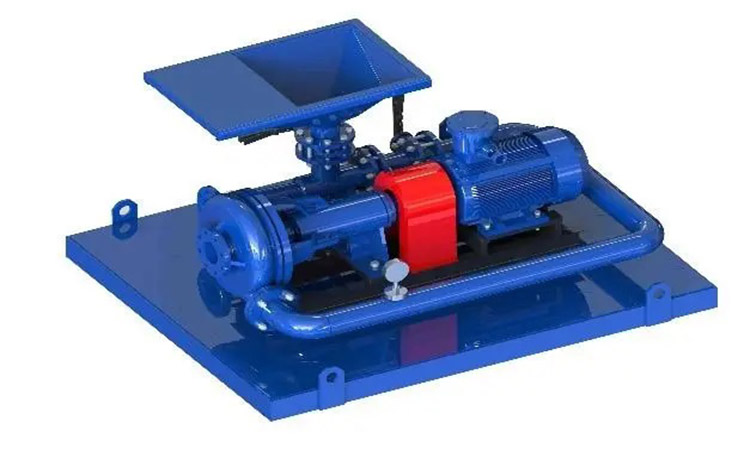

Jet mixing device is also called mud mixing Hoppers,Sino Mechanical mud mixing Hoppers are a kind of equipment specially used for mixing mud. They are a kind of equipment for adding drugs to the mud tank of oilfield drilling. They are mainly used for configuring and weighting drilling fluid, including single-jet mud mixing Hoppers and double-jet mud mixing Hoppers. The main components of mud mixing Hoppers include nozzles, mixing chambers, venturi tubes, hoppers and butterfly valves. This equipment plays an important role in oilfield drilling and other related fields

Precautions when installing the jet mixing device of Sino Mechanical solid control equipment

We all know that, like all equipment, the jet mixing device and related equipment of Sino Mechanical solid control equipment can only achieve ideal working performance if they are correctly selected, calibrated and reasonably installed.

(1) To meet the requirements of on-site slurry mixing. Generally, the processing capacity of the jet mixing device installed on Sino Mechanical solid control equipment shall not be less than 150m3/h. For special wells with large circulation tanks and high power of pump groups, a mixing funnel with a slurry mixing capacity of 300m3/h can also be selected. To ensure the need for well killing, it is recommended that each well team is equipped with a set of spare mixing funnels, which are connected to the system in parallel in most cases.

Once the drilling fluid funnel is determined, the pump, motor, feed pipeline and discharge pipeline must be reasonably designed to have a suitable flow rate under the recommended pressure head. For example, assuming that the displacement of the drilling fluid funnel is strictly required to be 2082l/min under a pressure head of 23m, the feed and discharge pipeline sizes should be selected according to the equipment instructions. The friction head loss of all pipelines and connections at a flow rate of 2082L/min must be determined, so the pressure head of 23m should be added to the funnel; the next step is to select a pump and impeller that can provide 2082L/min at the required total pressure head. When the pump is selected, the model of the motor that adapts to the drilling fluid density can be determined. If the maximum available drilling fluid density is unknown, it is recommended to use 2.4g/cm3 drilling fluid as the calculation basis.

(2) Minimize the resistance along the inlet and outlet pipelines, so the pipelines should be short and thick with smooth elbows. The jet funnel equipped with a corresponding venturi tube can improve the processing capacity, accelerate the solid phase diffusion and prevent agglomeration.

(3) Strengthen maintenance. In most cases, the back pressure should not be greater than 20% of the input pressure.

Another important consideration for installing equipment is the required height of drilling fluid lifting. If the discharge is to enter a tank on a different deck or a very high tank and funnel, the mixing rate will be reduced.

When the height is from 1.83-3.66m, the barite addition rate will decrease by 17%. If the lifting requirement is very high and the pump capacity is insufficient, the mixing capacity will be greatly reduced.

Supplier of mud mixing Hoppers

Sino Mechanical Equipment is a supplier of mud mixing Hoppers, providing various types ofSolids Control Systems, such as: Shale Shakers, Mud Cleaner, Decanter Centrifuge, Desanders and mud cleaner, Vacuum Degassers, Sand Pump, Mud Gas Separators, etc. Sino Mechanical Equipment is based in Shengli Oilfield, the second largest oilfield in China, and provides high-quality oil equipment and services to the world.