Precautions Before Lowering the Drill Pipe into the Well

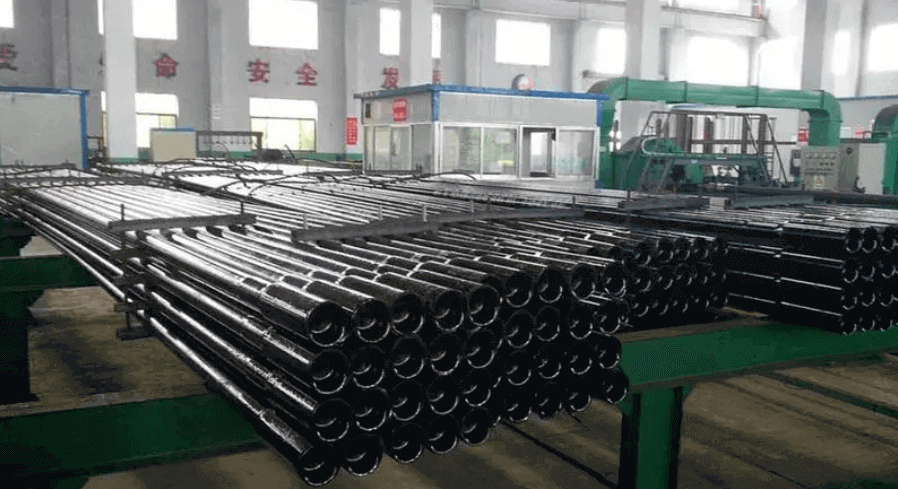

1. Storage and Preparation of Drill Pipes:

Before drill pipes are sent down the well, proper storage and preparation are imperative:

Drill pipes should be arranged according to specifications and neatly placed on mobile drill pipe racks with the internal threads of the joints facing the drilling rig, maintaining a distance of at least 0.3 meters above the ground.

Ensure that the drill pipe racks are kept parallel and on the same horizontal plane to prevent bending or deformation of the drill pipes.

Both ends of the drill pipes should be secured with blocks to prevent rolling and accidental falls.

2. Cleaning and Inspection:

Thorough cleaning and inspection are mandatory before sending drill pipes up the drilling rig:

Clean and inspect the threads of drill pipe joints and the sealing surfaces of the rig floor thoroughly, ensuring their integrity.

Confirm that there are no issues with the threads of the drill pipe joints and the rig floor sealing surfaces before proceeding.

During the process of hoisting drill pipes up and down the drilling rig, it is essential to wear thread protectors to prevent any damage to the threads and sealing surfaces during handling.

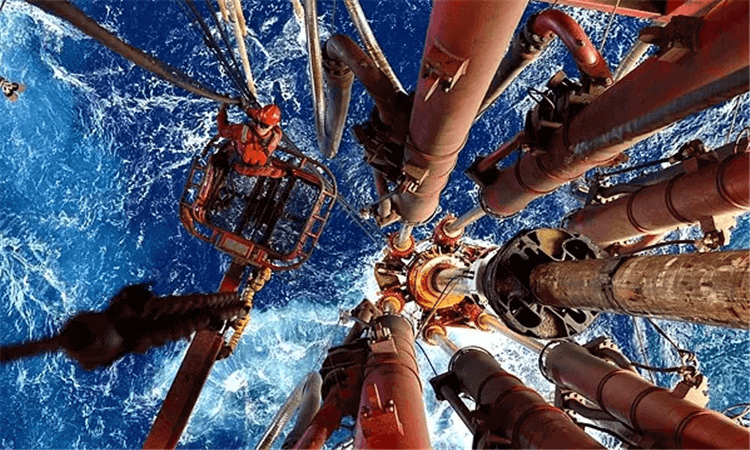

3. Safe Hoisting:

Safe hoisting measures must be taken when using a winch to send drill pipes up to the drilling rig:

Keep the winch as steady as possible to avoid vigorous swinging of the drill pipes during hoisting.

When the drill pipes are about to leave the slide track, use soft rope lines for manual control to prevent any collisions or damage.

4. Thread and Seal Application:

Before conducting single-joint operations at the wellhead, the following procedures must be followed:

Re-clean and re-inspect the threads of the drill pipe joints and the rig floor sealing surfaces, ensuring their cleanliness and integrity.

Apply an adequate amount of petroleum drilling-specific thread compound evenly to the threads of the drill pipe joints and the sealing surfaces of the rig floor. Ensure that it is applied uniformly to prevent damage to the threads and sealing surfaces.

Prevent dust and foreign particles from contaminating the thread compound to maintain its performance and to prevent scratching of the threads and sealing surfaces.

These precautions before lowering drill pipes down the well are essential to ensure the safety and performance of the equipment. Strict adherence to safety standards and best practices is paramount before any drilling operation to safeguard personnel and equipment.