Oilfield water injection pump

What is an oilfield water injection pump?

Oilfield water injection pump is one of the indispensable equipment in the oilfield exploitation process. It is mainly used to inject water into the bottom of the oil field through a high-pressure pump to form water column pressure, thereby driving the crude oil to rise to the surface and increasing oil field production. Oilfield water injection pumps usually include electric pumps and diesel pumps. The pumps are in the form of multi-stage centrifugal pumps and reciprocating pumps and etc..

Main types of oilfield water injection pumps

1. Centrifugal pump

Centrifugal pumps are one of the most widely used pumps in oil fields. It uses centrifugal force to pump liquid from the inlet to the outlet. It is generally installed on the ground and can be used to transport liquid oil and water. Because it has the characteristics of large flow, high lift, high efficiency and convenient use and maintenance, it has been widely used in different oil well projects.

2. Reciprocating pump

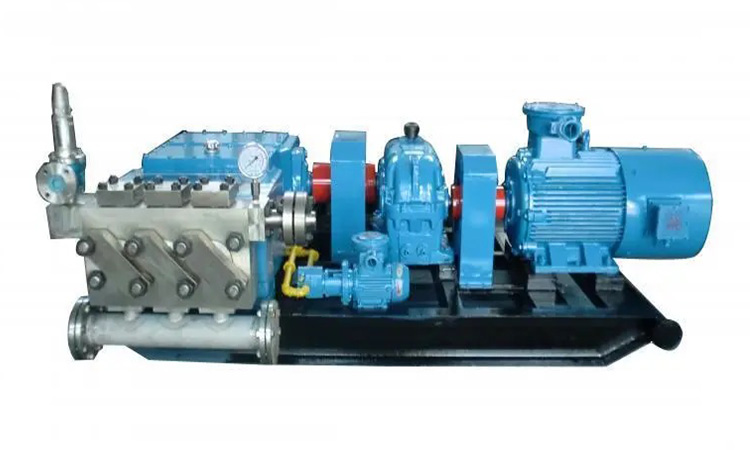

The plunger pump is a type of reciprocating pump that can work in high temperature and high pressure environments. It is mainly composed of hydraulic end, pump body and power mechanism. In oil fields, plunger pumps are mainly used for pressure control in water injection wells, oil production wells and fracturing wells. It can quickly compress, attract and deliver fluid to the pump head, and is suitable for high-pressure and low-flow delivery.

3. Screw pump

The screw pump is one of the pumps widely used in oil fields. It uses internal and external counter-rotating spiral gears to suck the oil from the inlet and then transport it to the outlet. The screw pump has the characteristics of small size, light weight, low power, high efficiency and low noise, and is suitable for excessive suction and transportation of high-viscosity liquids.

4. Diaphragm pump

The basic principle of a diaphragm pump is to use the lifting and lowering of the diaphragm to change the flow rate through a combination valve. It can work without oil and can also transport gas-containing or magnetic oil. In oil fields, diaphragm pumps are usually used in water irrigation, calcium carbonate, mud, etc.

The function of oilfield water injection pumps

1. Increase oil field production

Oilfield water injection pumps help crude oil rise to the surface by injecting water into the bottom of the well to create water column pressure. Since crude oil production is directly proportional to bottom-hole pressure, increasing bottom-hole pressure through a water injection pump can greatly increase the production of oil fields.

2. Protect oil wells

Various problems may occur during the production of oil wells. For example, insufficient formation pressure leads to a decrease in bottom hole pressure, resulting in a reduction in production. By injecting an appropriate amount of water, the oil well can be protected while increasing the bottom hole pressure, thereby extending the life of the oil well.

3. Promote comprehensive utilization

Oilfield water injection pumps can not only be used to increase the production of oil fields, but can also be used to inject cement to fix well walls, inject acid to corrode formations, inject hydraulic sand to advance fractures, and other purposes to promote comprehensive utilization of oil fields.

3. Precautions for oilfield water injection pumps

When using oilfield water injection pumps, you need to pay attention to the following points:

1. The amount of water injected should be reasonably configured according to the oil field conditions and water quality to ensure an increase in production.

2. The water injection pump needs to be inspected and maintained regularly to ensure its normal operation.

3. When selecting an oilfield water injection pump, it is necessary to make a reasonable selection based on well depth, pressure, pump efficiency, etc., to avoid waste or loss caused by selecting an inappropriate pump.

4. Keep the water in the oil well clean to avoid problems such as impurities and sediments that affect production.

Summary of oilfield water injection pumps

As one of the important equipments in oilfield exploitation, oilfield water injection pump increases the bottomhole pressure by injecting water into the bottom of the well, thereby helping the crude oil rise to the surface and promoting the exploitation and comprehensive utilization of the oilfield. When using a water injection pump, certain precautions need to be followed to ensure the normal operation of the equipment and increase oil field production.

Supplier of Oilfield water injection pumps

Sino Mechanical Equipment is a supplier of oilfield water injection pumps, providing centrifugal pumps, plunger pumps, screw pumps, diaphragm pumps, etc. Sino Mechanical Equipment is based on Shengli Oilfield, the second largest oil field in China, and provides high-quality petroleum equipment and services to the world.