How to improve the performance of drilling sucker rods?

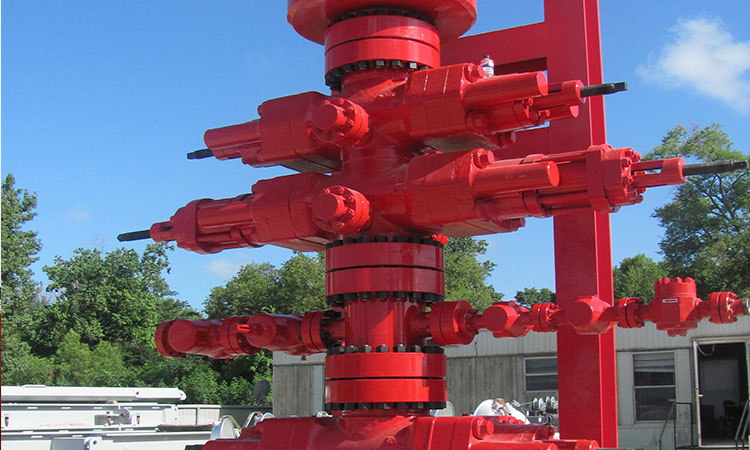

The main role of a sucker rod in drilling operations is to transmit power from the surface pumping unit to the downhole pump in a reciprocating motion. Sucker rods are part of the rod string, which connects the pumping unit at the surface to the downhole pump in the wellbore.

Overall, sucker rods play a crucial role in the artificial lift process, where they provide the mechanical means to lift fluids from the wellbore. Their proper selection, design, and maintenance are essential for efficient and reliable drilling operations.

To improve the performance of drilling sucker rods, you can consider the following strategies:

Material Selection: Choose high-quality materials with superior strength and durability. Common materials used for sucker rods include steel alloys such as AISI 4130 or 4140. Selecting the right material can enhance the rods' ability to withstand high stresses and corrosion.

Rod Design: Optimize the design of the sucker rods to maximize their performance. Consider factors such as rod diameter, length, taper, and thread profile. Engineering the rods for increased strength and reduced weight can enhance their drilling efficiency.

Heat Treatment: Apply appropriate heat treatment processes to the sucker rods to enhance their mechanical properties. Processes such as quenching and tempering can improve the rods' hardness, strength, and resistance to fatigue.

Lubrication and Maintenance: Proper lubrication is crucial to reduce friction and wear between the sucker rods and the tubing. Regular maintenance and inspection can help identify any defects or signs of wear and address them promptly, preventing failures and improving overall performance.

Corrosion Prevention: Implement effective corrosion prevention measures to protect the sucker rods from degradation. Coatings, such as zinc or other corrosion-resistant materials, can be applied to the rods to increase their lifespan and performance.

Rod String Design: Evaluate the overall design of the rod string, including the configuration and placement of the rods within the wellbore. Optimizing the rod string design can reduce stress concentrations, minimize rod buckling, and improve drilling efficiency.

Upgrading Pumping System: Consider upgrading the pumping system to ensure optimal performance of the sucker rods. This includes selecting the appropriate pumping unit and optimizing the rod string length, diameter, and weight to match the well's characteristics.

Training and Monitoring: Provide proper training to the drilling personnel to ensure correct handling and installation of the sucker rods. Implement monitoring systems to track the performance of the rods, including load monitoring, stress analysis, and fatigue monitoring.

By implementing these strategies, you can improve the performance, reliability, and longevity of drilling sucker rods, leading to increased drilling efficiency and reduced downtime.

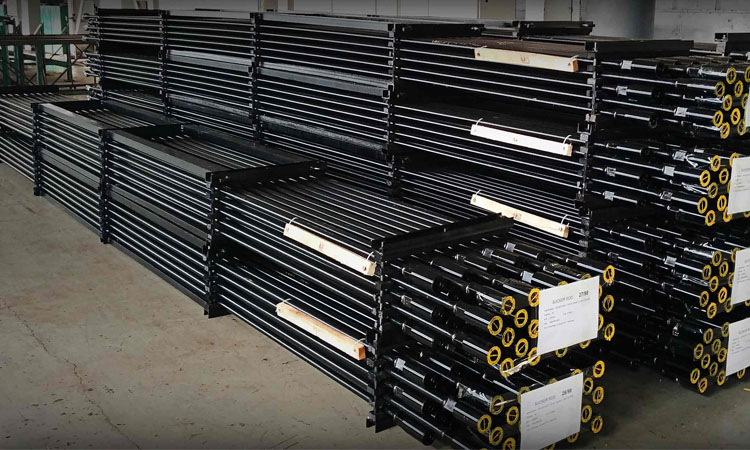

Sino Mechanical, as a Sucker Rods manufacturer, has more than 20 years extensive experiences in the performance, application and cost-effective manufacturing of Sucker Rods. We are global Sucker Rods supplier. We offer a wide range of drilling equipment and have Sucker Rods for sale. We also provide OEM services.

As a sucker rod manufacturer, our steel sucker rods, and pony rods are manufactured to the highest quality standards to ensure reliable, consistent operation in every well application.