How to Efficiently Remove Drill Cuttings from Drilling Mud?

Efficient removal of drill cuttings from drilling mud is a crucial aspect of drilling operations. It helps maintain the performance and quality of the drilling fluid, enhances drilling efficiency, and reduces potential issues. Here are some methods to effectively remove drill cuttings from drilling mud:

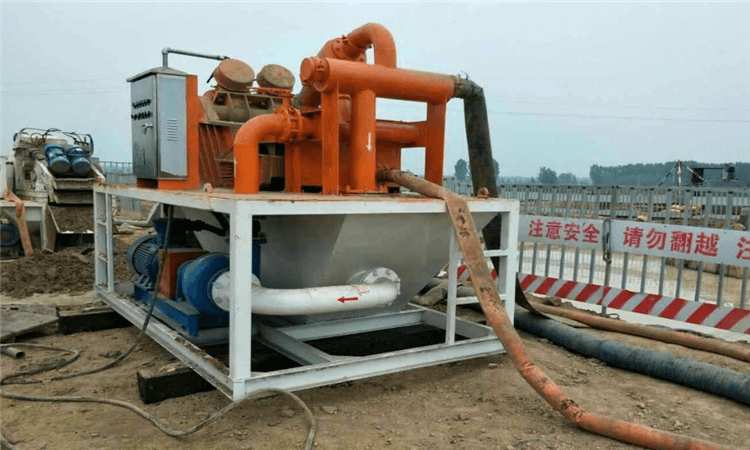

Use of Mud Cleaners: Mud cleaners are specialized equipment designed to remove solid particles, including drill cuttings, from drilling mud. They use a combination of screens and hydrocyclones to separate and clean the mud, ensuring that it remains free of larger particles.

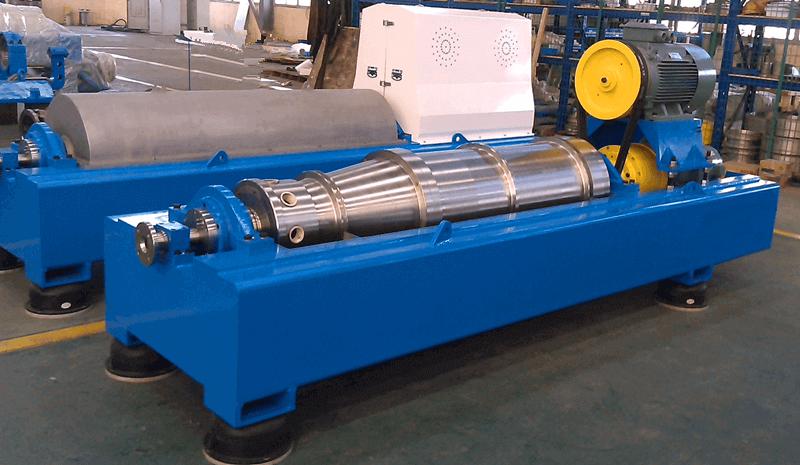

Decanter Centrifuges: Decanter centrifuges are powerful tools that use centrifugal force to separate solids from drilling mud. They can effectively remove fine particles, including drill cuttings, from the mud, ensuring a cleaner drilling fluid.

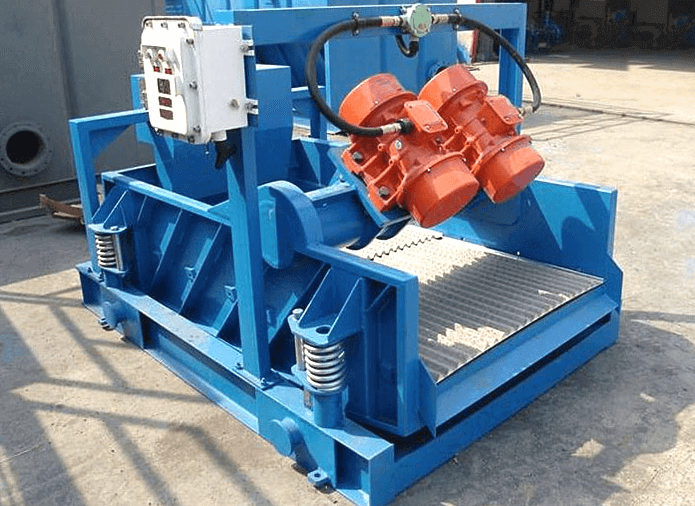

Shale Shakers: Shale shakers are commonly used to remove larger drill cuttings from the drilling mud. They use a vibrating screen to separate the cuttings from the mud, allowing the clean mud to flow back into the system.

Proper Mud Mixing and Dilution: Maintaining the right mud density and viscosity through proper mixing and dilution can help prevent the accumulation of drill cuttings. Diluted mud is more effective at carrying cuttings to the surface.

Continuous Monitoring: Regularly monitor the drilling mud properties, including density, viscosity, and solid content. Adjustments can be made in real-time to ensure that the mud remains effective at removing and carrying cuttings.

Optimized Drilling Practices: Implement drilling practices that minimize the generation of cuttings. This may include optimizing drilling parameters, such as the type of bit and the rate of penetration.

Efficient Mud Removal and Cleaning: Implement efficient methods for removing and cleaning the drilling mud as it returns to the surface. This may involve the use of mud pits, mud cleaning equipment, and proper disposal practices.

Periodic Mud Replacement: While continuous cleaning is important, periodically replacing a portion of the drilling mud with fresh mud can help maintain its effectiveness in carrying cuttings.

Advanced Filtration Techniques: Consider using advanced filtration techniques, such as cartridge filters or mesh screens, to further remove fine particles from the drilling mud.

Operator Training: Ensure that drilling personnel are trained in proper drilling practices and mud management techniques to minimize the generation and accumulation of drill cuttings.

By incorporating these strategies, drilling operations can effectively manage and remove drill cuttings from the drilling mud, ensuring a cleaner and more efficient drilling process. Proper management of drill cuttings contributes to improved drilling performance, reduced equipment wear, and enhanced environmental responsibility.