How to Choose a Suitable Drilling Mud Tank System

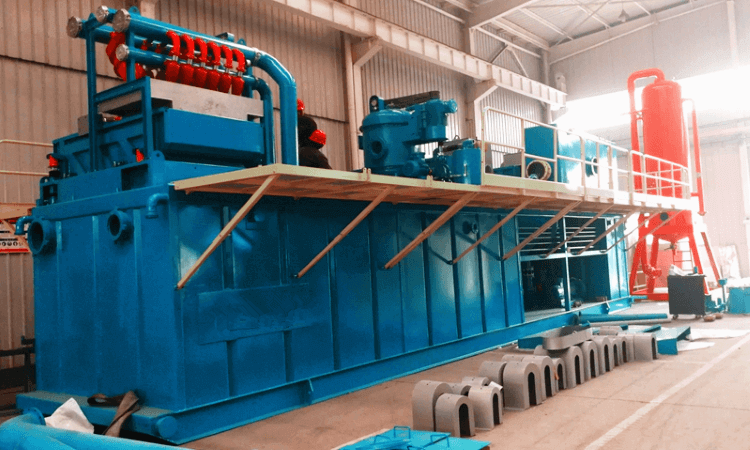

The Drilling Rig Mud Tank System is a critical component of modern oil drilling operations. It plays a pivotal role in storing, circulating, and conditioning drilling mud to ensure the smooth and efficient progress of drilling activities. As a reputable manufacturer of mud tanks, Sino Mechanical is committed to assisting customers in selecting the most suitable Drilling Rig Mud Tank System that caters to their specific drilling requirements. In this article, we will guide you through the essential factors to consider when choosing the right mud tank system for your drilling operations.

1.Evaluate Your Drilling Needs:

The first step in selecting the appropriate mud tank system is to assess your drilling needs thoroughly. Consider the scale of your drilling project, the volume of mud required, the type of drilling fluids, and any specific challenges or environmental conditions unique to your operation. This evaluation will help you determine the appropriate size, capacity, and features required for the mud tank system.

2.Understand Different Mud Tank Types:

Mud tank systems come in various types, each designed to cater to specific drilling requirements. Some common types include solid control system mud tanks, skid-mounted vehicle mud tanks, and buried tanks. Understand the unique features and benefits of each type to select the one that aligns best with your drilling project.

3.Quality and Material:

The quality of the mud tank system is of utmost importance to ensure its durability and reliability in demanding drilling environments. Sino Mechanical uses high-quality materials and adheres to industry standards to produce robust mud tanks capable of withstanding harsh conditions. Consider the manufacturing standards, corrosion-resistant coatings, and structural integrity of the tanks to ensure long-term performance.

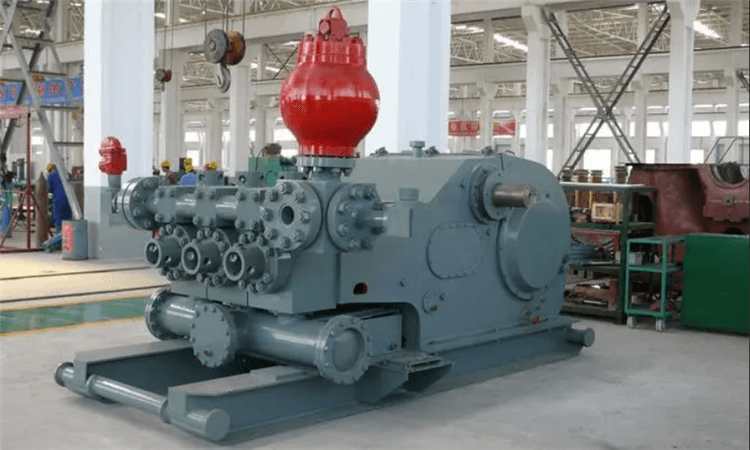

4.Supporting Equipment:

The effectiveness of a mud tank system is enhanced by the supporting equipment integrated into it. Ensure that the mud tank comes equipped with essential devices such as drilling fluid shale shakers, desanders, desilters, agitators, and mud pumps. These components are crucial for efficient solid control, mud conditioning, and circulation during drilling operations.

5.Safety and Environmental Considerations:

Safety is paramount in drilling operations. Ensure that the mud tank system is designed with safety features, such as non-slip surfaces, secure guardrails, and emergency shutdown systems. Additionally, choose a system with environmental safeguards to prevent spillage and minimize any ecological impact.

6.Customization Options:

Every drilling project is unique, and a one-size-fits-all approach may not suffice. Opt for a manufacturer like Sino Mechanical that offers customization options. This ensures that the mud tank system can be tailored to meet your specific operational requirements and enhance overall efficiency.

7.Technical Support and After-Sales Service:

Select a supplier that provides excellent technical support and after-sales service. Sino Mechanical offers comprehensive assistance, including installation guidance, maintenance support, and spare parts availability. Having reliable technical support ensures seamless integration of the mud tank system into your drilling operations.

Choosing the right Drilling Rig Mud Tank System is critical for the success and efficiency of drilling operations. By carefully evaluating your drilling needs, understanding different mud tank types, considering the quality and material, examining supporting equipment, prioritizing safety and environmental considerations, exploring customization options, and seeking reliable technical support, you can make an informed decision and select a mud tank system that optimally meets your drilling requirements. As a trusted manufacturer, Sino Mechanical is here to provide you with the ideal mud tank solution tailored to your drilling project's unique demands.