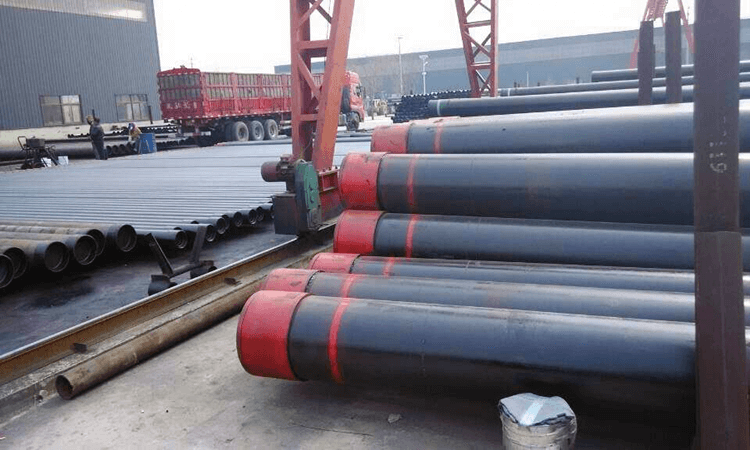

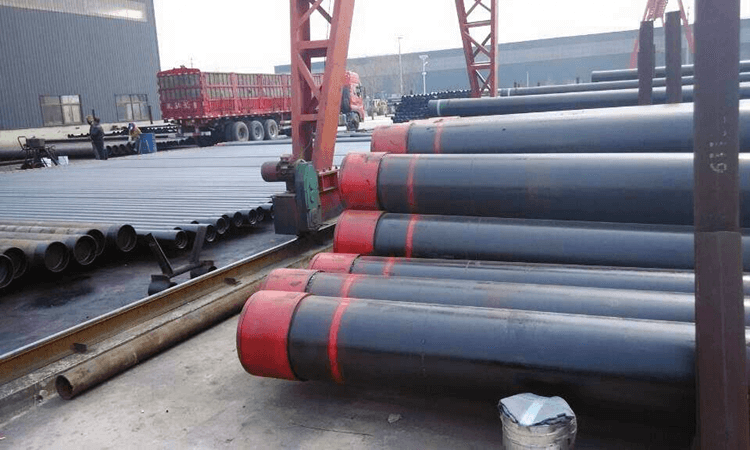

Excellent Application of Steel Casing Pipes in Deep Oil and Gas Drilling

An international petroleum company planned an exploratory well in a deep oil and gas reservoir, anticipating a well depth of several thousand meters. Due to the depth of the reservoir, geological characteristics, and well depth requirements, high-strength, corrosion-resistant steel casing pipes were chosen as key components for wellbore protection and formation stability.

The client selected high-strength, corrosion-resistant API 5CT N80 or L80 grade steel casing pipes. These pipes not only possess sufficient strength to withstand the challenges of deep well environments but also ensure the long-term stability of the wellbore through their corrosion-resistant properties.

During the drilling process, one of the primary roles of steel casing pipes is to ensure the stability of the wellbore. As the well depth increases, the wellbore faces increased formation pressure and the risk of wellbore collapse. The correct selection of appropriately sized casing pipes helps maintain the integrity of the wellbore and prevents formation collapse.

Deep oil and gas reservoirs typically contain various types of formations, including organic-rich shale, sandstone, and more. Steel casing pipes form an effective barrier in the wellbore, preventing the infiltration of groundwater, oil, and gas, thereby safeguarding the stability of the formation. This is crucial for protecting mineral resources within the reservoir and ensuring the long-term sustainable extraction of the well.

Throughout the drilling process, the engineering team monitored the performance of the steel casing pipes, including wellbore stability, corrosion resistance, and overall structural integrity, validating the excellent performance of the pipes in deep well environments. The steel casing pipes successfully navigated various geological and engineering challenges, ensuring the smooth progress of the drilling project.

By correctly selecting and applying steel casing pipes, the oil and gas drilling project successfully achieved its objectives. Wellbore stability was ensured, the formation received effective protection, and no major technical failures occurred during the entire drilling process. This not only increased production efficiency but also lowered operational costs, ensuring the sustainable extraction of the well in the future.

This project case highlights the critical importance of correctly selecting and applying high-quality steel casing pipes to ensure the success and economic benefits of drilling. Sino Mechanical supplies tubing and casing that comply with API 5CT standards, ensuring rapid delivery and optimal prices.